Continuous-fiber-enhanced thermoplastic resin wound pipe and method for forming same

A technology for reinforcing thermoplastic and continuous fibers, applied in rigid pipes, pipes, pipes/pipe joints/fittings, etc., can solve the problems of difficult preparation technology, no substantial progress, difficult hardness, etc., and achieve short molding cycle, light weight, The effect of good impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Take continuous glass fiber reinforced polypropylene prepreg tape as raw material, first process the prepreg tape into a strip with a width of 30 mm, coil it on the unwinding device, and then pull the prepreg tape through the guide roller and tension control device To the top of the winding mandrel, the winding equipment adopts a self-designed three-axis linkage CNC winding machine. The heating method adopts combined use of infrared light box heating and hot air gun. The infrared light box heating is a pre-heating process. Winding speed, the heating temperature used is 300°C, and then heated by a heat gun. The heating position is at the contact joint between the prepreg tape and the winding mandrel. The heating temperature is to make the surface temperature of the prepreg tape 180°C. During the winding process, the pressure roller Apply 0.1MPa pressure. The winding speed was 5 m / min. Cross winding 10 layers of prepreg tape, the shape of the winding tube is round. Aft...

Embodiment 2

[0031] Take continuous glass fiber reinforced polyethylene prepreg tape as raw material, first process the prepreg tape into a strip with a width of 30 mm, coil it on the unwinding device, and then pull the prepreg tape through the guide roller and tension control device To the top of the winding mandrel, the winding equipment adopts a self-designed three-axis linkage CNC winding machine. The heating method adopts combined use of infrared light box heating and hot air gun. The infrared light box heating is a pre-heating process. Winding speed, the heating temperature used is 280°C, and then heated by a heat gun, the heating position is at the contact joint between the prepreg tape and the winding mandrel, and the heating temperature is to keep the surface temperature of the prepreg tape at 150°C. The winding speed was 5 m / min. Cross winding 10 layers of prepreg tape, the shape of the winding tube is round. After the winding is completed, heat the pipe surface at 280°C and ap...

Embodiment 3

[0033] A continuous fiber reinforced thermoplastic resin winding pipe forming method, comprising the following steps:

[0034] (1) Use infrared ceramics to heat the fiber-reinforced resin prepreg sheet, the fiber in the sheet is carbon fiber, and melt the polymethyl methacrylate resin in the prepreg sheet to soften the entire prepreg sheet , the prepreg sheet used can use the prepreg material produced by Liaoning Jieshijie New Material Co., Ltd.;

[0035] (2) Apply tension to the prepreg tape after heating, so that the prepreg tape is tensioned under the action of tension, and wind ten layers on the circular winding mandrel at a winding angle of 70°, and the number of winding layers is based on the Depending on the requirements of the pipe pressure;

[0036] (3) During the winding process, apply a pressure of 0.1MPa on the surface of the pipe by the pressure roller to increase the bonding strength of the pipe;

[0037] (4) After the winding is completed, heat the surface of ...

PUM

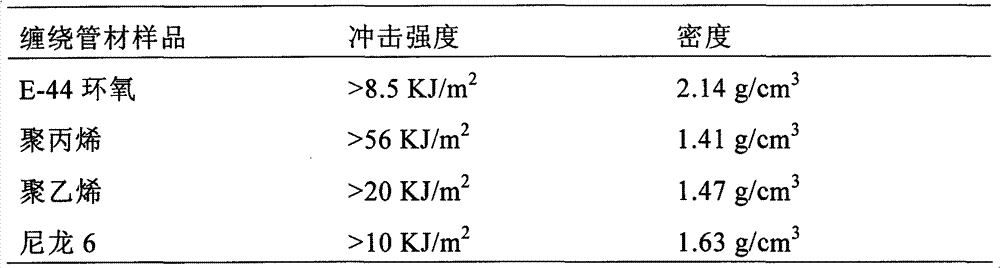

| Property | Measurement | Unit |

|---|---|---|

| Winding angle | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com