Free-form surface micro lens array for LED (light-emitting diode) headlamp of automobile

A technology of automotive headlights and microlens arrays, which is applied to the components of lighting devices, lighting devices, lighting and heating equipment, etc., can solve the problems of chip array influence, complex optical design, and complex optical system, etc., to achieve light control Direction, high design flexibility, and the effect of reducing the loss of light energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

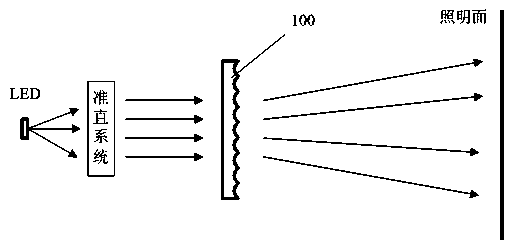

[0043] The light distribution principle of the free-form surface optical microlens array 100 for the LED automobile headlamp provided by the present invention is as follows: figure 1 (the arrow in the figure indicates the direction of the beam). Since the national standard GB25991-2010 imposes light distribution requirements on both the low beam and the high beam of LED automobile headlamps, and the requirements for the low beam are particularly strict, the specific implementation is described by taking the design of the low beam as an example.

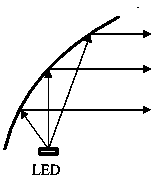

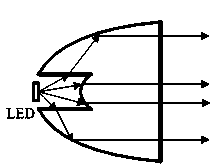

[0044] First of all, the light emitted by the LED light source needs to be collimated. The collimation effect can be achieved by reflection or refraction, such as Figure 2a , Figure 2b As shown, the light is collimated and exits as a parallel beam.

[0045] Then, mesh the illuminated area ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com