Lead-acid cell cathode lead-paste modified by grapheme dispersion liquid, and preparation method thereof

A graphene dispersion, lead-acid battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as low specific energy of lead-acid batteries, reduce current density, reduce electrochemical polarization, and be suitable for large-scale production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

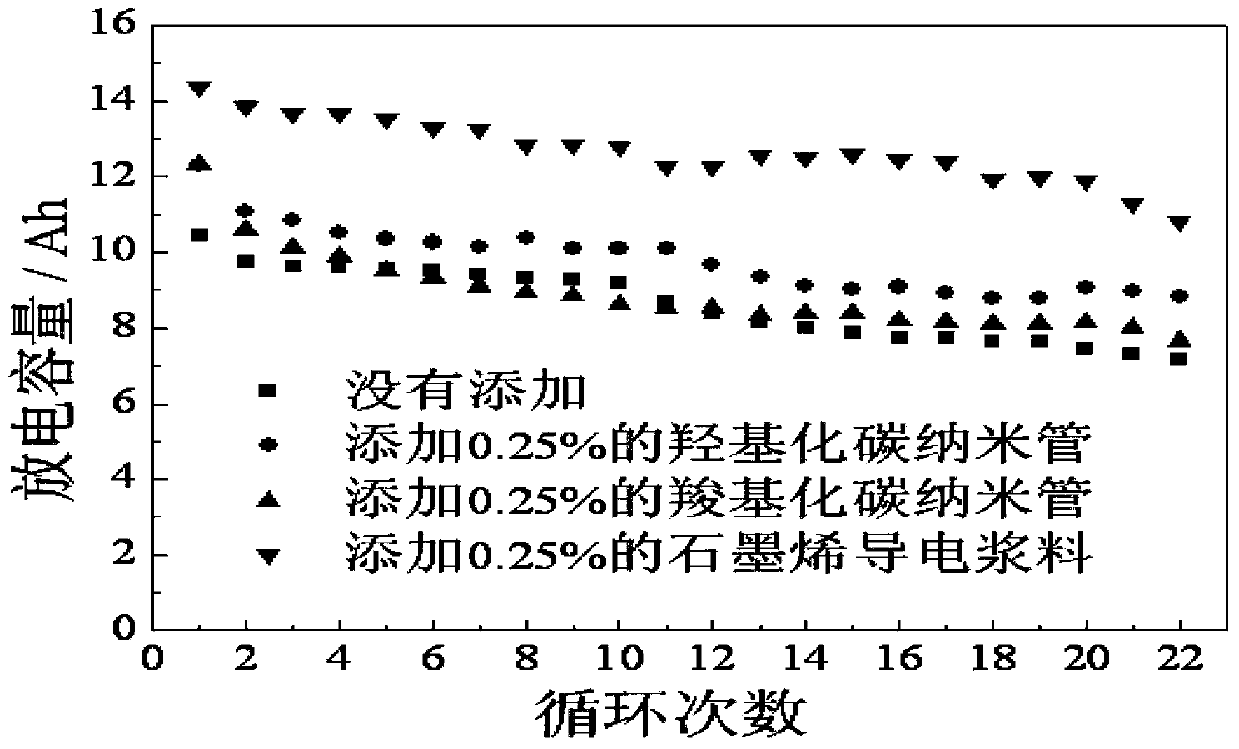

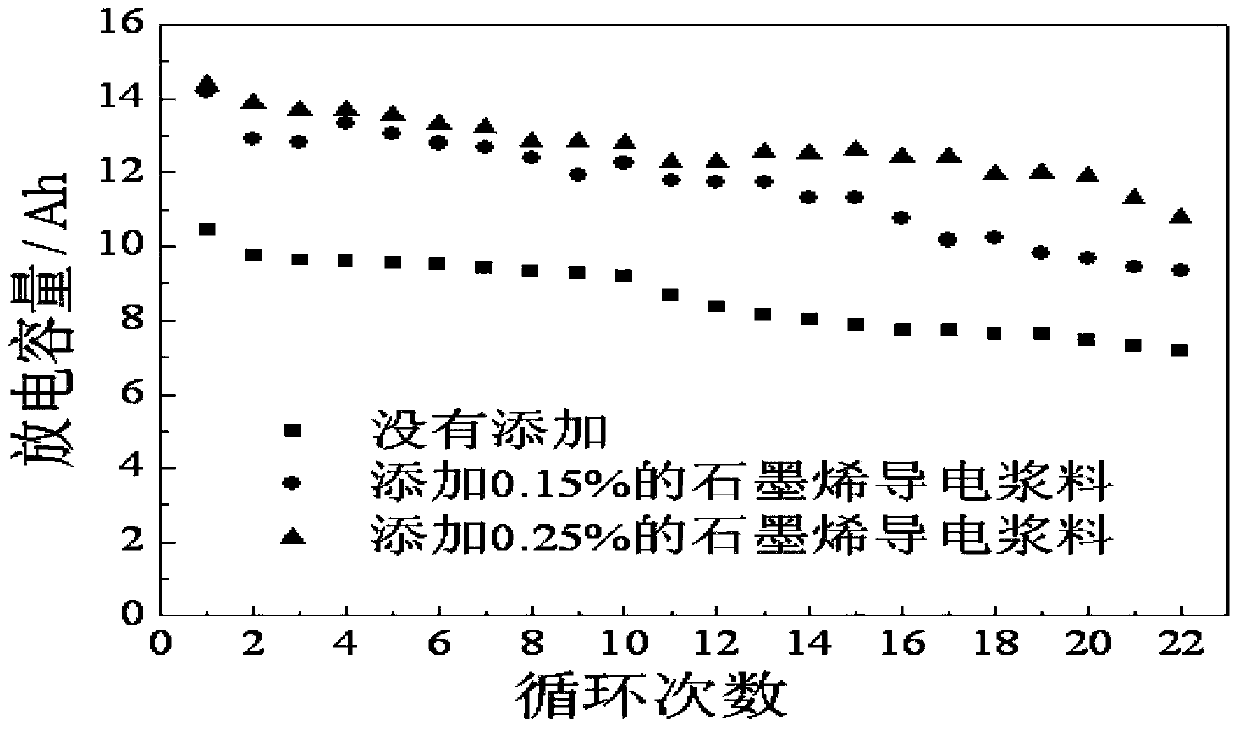

[0022] Preparation of lead-acid battery: The mass of lead powder in the paste formula of the negative electrode test is 3000g, the fiber is 2.1g, the acetylene black is 15g, and the barium sulfate is 24g. Mix for 10 minutes, then add the dispersed graphene aqueous dispersion into the paste mixer (according to the mass of the hydrophilic treated graphene is 0.15% of the mass of the lead powder), then add 270g of dilute sulfuric acid, and mix for 10 minutes , measure the apparent density, the apparent density should be 4.0g / cm 3 Add water according to the measured apparent density. Coat the reconciled lead paste on the negative grid. The weight of each wet plate is controlled at 320±3g. 3000g of lead paste can coat about 15±1 plates. Assembled into a 12Ah 2V lead-acid battery, with glass fiber cotton as the diaphragm, and the filling density is 1.325g / cm 3 The sulfuric acid aqueous solution is used as the electrolyte, and the battery is internalized to form a good lead-acid ba...

Embodiment 2

[0024] Preparation of lead-acid battery: The mass of lead powder in the paste formula of the negative electrode test is 3000g, the fiber is 2.1g, the acetylene black is 15g, and the barium sulfate is 24g. Mix for 10 minutes, then add the dispersed graphene aqueous dispersion into the paste mixer (according to the mass of the hydrophilic treated graphene is 0.25% of the mass of the lead powder), then add 270g of dilute sulfuric acid, and mix for 10 minutes , measure the apparent density, the apparent density should be 4.0g / cm 3 Add water according to the measured apparent density. Coat the reconciled lead paste on the negative grid. The weight of each wet plate is controlled at 320±3g. 3000g of lead paste can coat about 15±1 plates. Assembled into a 12Ah 2V lead-acid battery, with glass fiber cotton as the diaphragm, and the filling density is 1.325g / cm 3 The sulfuric acid aqueous solution is used as the electrolyte, and the battery is internalized to form a good lead-acid ba...

Embodiment 3

[0026] Preparation of lead-acid battery: The mass of lead powder in the paste formula of the negative electrode test is 3000g, the fiber is 2.1g, the acetylene black is 15g, and the barium sulfate is 24g. Mix for 10 minutes, then add the dispersed graphene aqueous dispersion into the paste mixer (according to the mass of the hydrophilic treated graphene is 0.20% of the mass of the lead powder), then add 270g of dilute sulfuric acid, and mix for 10 minutes , measure the apparent density, the apparent density should be 4.0g / cm 3 Add water according to the measured apparent density. Coat the reconciled lead paste on the negative grid. The weight of each wet plate is controlled at 320±3g. 3000g of lead paste can coat about 15±1 plates. Assembled into a 12Ah 2V lead-acid battery, with glass fiber cotton as the diaphragm, and the filling density is 1.325g / cm 3 The sulfuric acid aqueous solution is used as the electrolyte, and the battery is internalized to form a good lead-acid ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com