Manufacturing method of plastic fuel tank containing EVOH (Ethylene-Vinyl Alcohol Copolymer) barrier layer

A manufacturing method and fuel tank technology, applied to chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems of complex molding process and large degree of freedom in modeling design of plastic fuel tanks, and achieve easy processing The control and preparation methods are simple and easy, and the effect of fewer layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

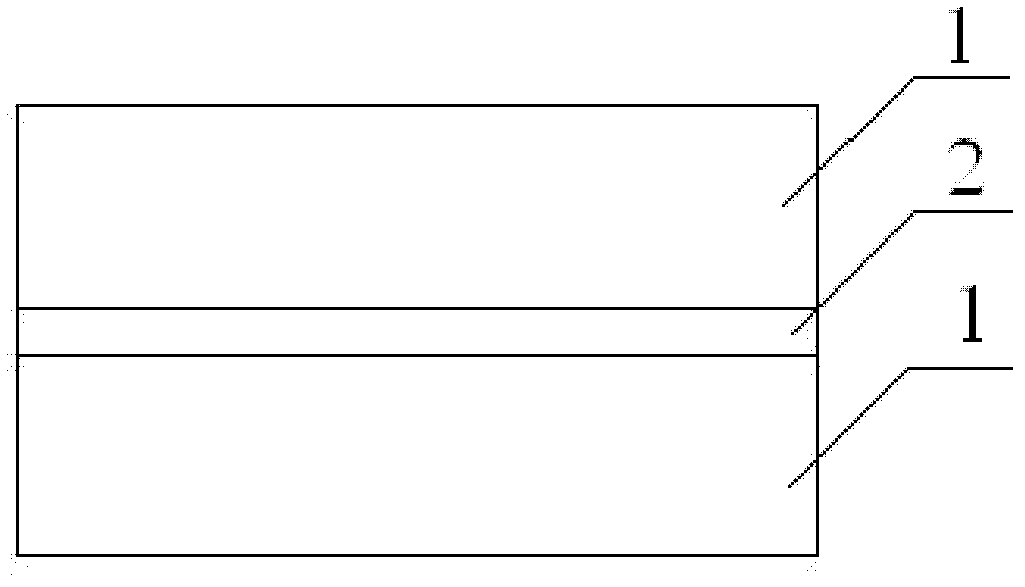

[0028] A method for making a plastic fuel tank containing an EVOH barrier layer. The polyethylene resin sheet 1 and the ethylene-vinyl alcohol copolymer film 2 are compounded by a compound machine to form a top-down structure in sequence of polyethylene resin layer, ethylene-ethylene The three-layer sheet of alcohol copolymer layer and polyethylene resin layer, the working pressure of the compound machine is 15MPa, the three-layer sheet is sent into the pressing mold of the plastic fuel tank, the molding temperature is controlled at 150 ° C, and the molding is produced. Plastic fuel tank.

[0029] In this implementation, the polyethylene resin sheet used is HDPE resin (grade: Iran Petrochemical HDPE 52518), which is plasticized and melted at a temperature of 170-200°C, and extruded to obtain HDPE sheet. The grade of EVOH film pre-coating adhesive is Mitsui ADMERNF528H, two pieces of HDPE sheets and EVOH film are compounded by a compound machine to form a three-layer sheet with...

Embodiment 2

[0031] A method for making a plastic fuel tank containing an EVOH barrier layer, in which a polyethylene resin sheet and an ethylene-vinyl alcohol copolymer film are compounded by a compound machine to form a top-down structure, followed by polyethylene resin layer, ethylene-vinyl alcohol copolymer Material layer, polyethylene resin layer three-layer board, the working pressure of the composite machine is 16MPa, the three-layer board is sent to the pressing mold of the plastic fuel tank, the molding temperature is controlled at 160 ° C, and the plastic fuel tank is produced by molding. box.

[0032] In this implementation, the polyethylene resin sheet used is HDPE resin (grade: Fushun ethylene HDPE 2911), which is plasticized and melted at a temperature of 170-200°C, and then extruded to obtain a HDPE sheet. The grade of the EVOH film pre-coated adhesive is Mitsui ADMER AT1809, two pieces of HDPE sheet and EVOH film are compounded by a compound machine to form a three-layer sh...

Embodiment 3

[0034] A method for making a plastic fuel tank containing an EVOH barrier layer. The polyethylene resin sheet 1 and the ethylene-vinyl alcohol copolymer film 2 are compounded by a compound machine to form a top-down structure in sequence of polyethylene resin layer, ethylene-ethylene Alcohol copolymer layer, polyethylene resin layer three-layer plate, the working pressure of the composite machine is 18MPa, such as figure 1 shown. The three-layer board is fed into the pressing mold of the plastic fuel tank, the molding temperature is controlled to be 150° C., and the plastic fuel tank is produced by molding.

[0035] Wherein, the polyethylene used is a high-density polyethylene resin, and the high-density polyethylene is extruded to obtain a polyethylene resin sheet, and the ethylene-vinyl alcohol copolymer film and the polyethylene resin sheet are bonded by an adhesive maleic anhydride. The plastic fuel tank press mold is composed of an upper mold for making the upper part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com