Method for preparing reinforced fluoropolymer composites comprising surface functionalized nanocrystalline cellulose

A nano-microcrystalline and cellulose technology, applied in the field of nano-microcrystalline cellulose, can solve the problems of limited filler properties and difficult dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0090] 1. A method of preparing a reinforced fluoropolymer composite, the method comprising:

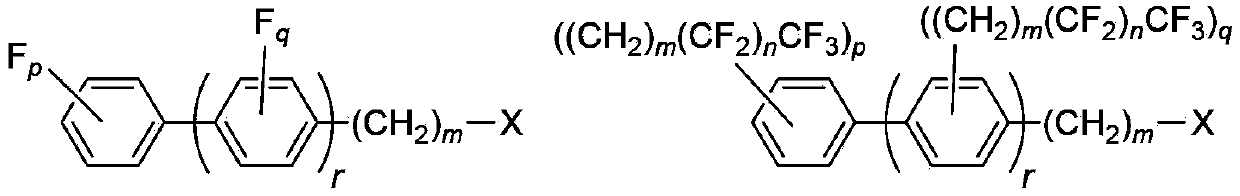

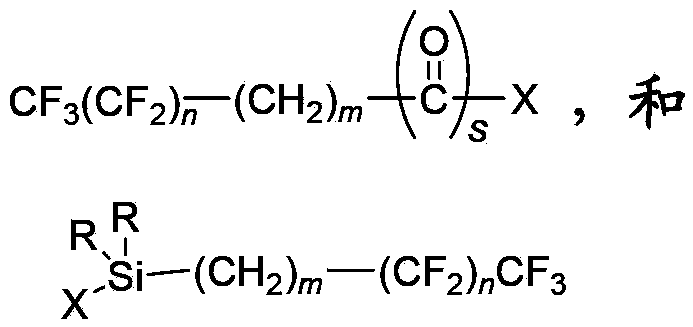

[0091] reacting the surface of nanocrystalline cellulose with a fluorinated electrophile to form fluorine-functionalized nanocrystalline cellulose, wherein the periphery of the nanocrystalline cellulose is functionalized with a fluorine-containing substrate; and

[0092] The fluorofunctionalized nanocrystalline cellulose is contacted with a fluoropolymer to form a fluoropolymer composite.

[0093] 2. The method of 1 above, wherein the reaction of the fluorinated electrophile and the nanocrystalline cellulose is carried out under heterogeneous conditions.

[0094] 3. The method of 1 above, wherein the nanocrystalline cellulose is rod-shaped crystalline nanoparticles having a crystal structure.

[0095] 4. The method of 1 above, wherein the reaction of the surface of the nanocrystalline cellulose with the fluorinated electrophile does not reduce the size of the nanocrystalline cellulo...

Embodiment 1

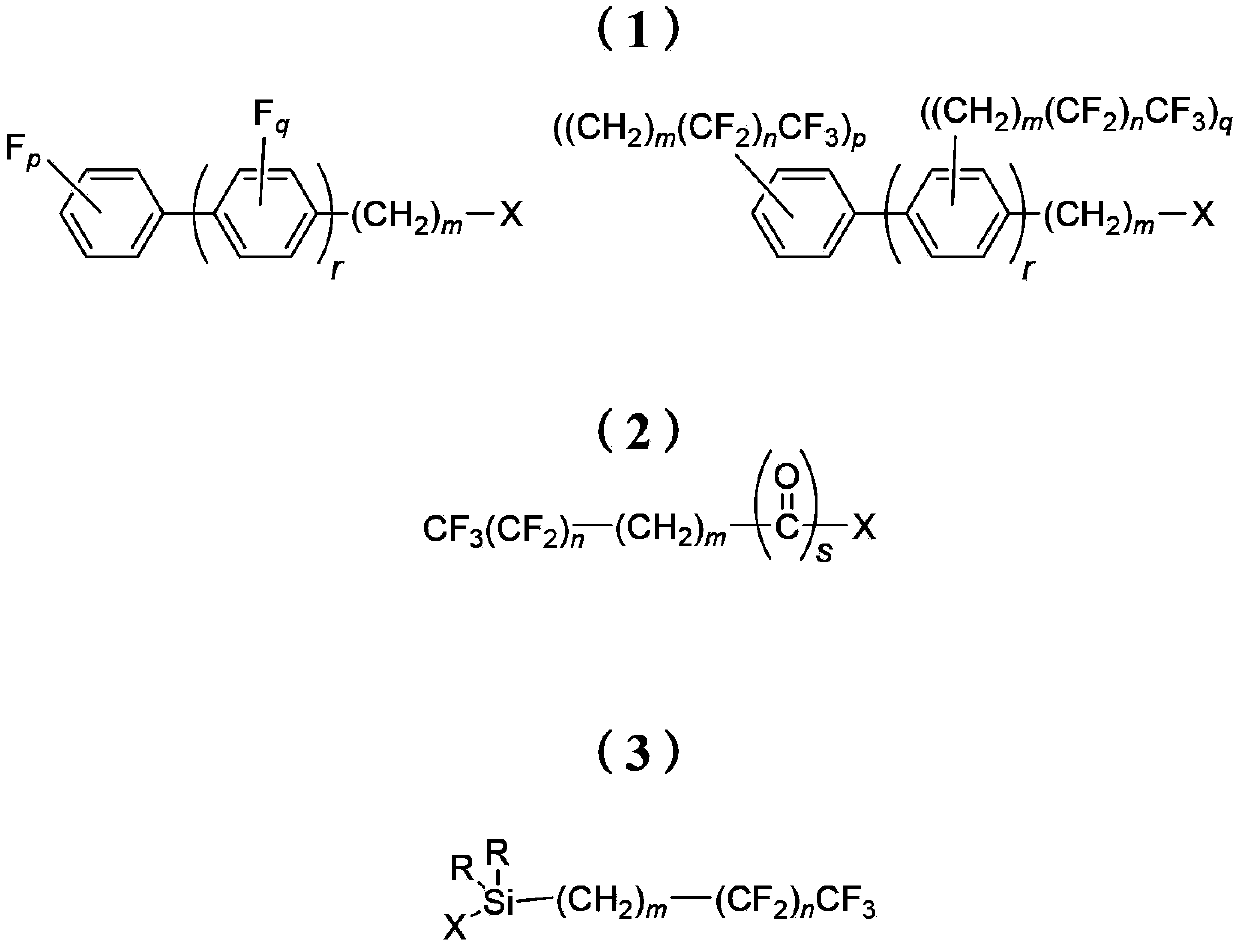

[0131] Example 1 - Functionalization of NCC surfaces using perfluoroalkyldimethylchlorosilanes

[0132] The suspension with the desired amount of nanocrystalline cellulose (2 g in 100 g of methanol; 2% by weight) was solvent exchanged into acetone by several successive centrifugations and redispersions and subsequently dried toluene. Sonication was performed after each solvent exchange. The suspension was transferred to a three-neck round bottom flask and filled with argon. Excess heptadecafluoro-1,1,2,2-tetrahydrodecyldimethylchlorosilane (purchased from Gelest Inc.) was added dropwise to the stirring suspension. A solution of an organic amine base (eg imidazole) is added dropwise after the addition of the silane and the reaction temperature is monitored so that the reaction does not exceed 50°C. The reaction was stirred at room temperature for 16 hours. Subsequently, the modified material was separated by centrifugation and washed with ethanol four times at 10000 rpm per ...

Embodiment 2

[0133] Example 2 - Functionalization of NCC surfaces using 2H,2H,3H,3H-perfluorodecanoic acid

[0134] The suspension with the desired amount of nanocrystalline cellulose (2 g in 100 g of methanol; 2% by weight) was solvent exchanged into acetone by several successive centrifugations and redispersions and subsequently dried to toluene. Sonication was performed after each solvent exchange. The suspension was transferred to a three-neck round bottom flask and excess 2H,2H,3H,3H-perfluorodecanoic acid (purchased from SynQuest Laboratories) was added to the stirring suspension followed by a catalytic amount of p-toluenesulfonate acid. Surface modification of cellulose nanostructures was performed at 105°C for up to 24 hours. After surface treatment, the material was purified and dried in the same manner as in Example 1.

[0135] Formation of the NCC complex

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com