Full-automatic hydraulic pile breaker

A pile cutting machine, fully automatic technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems affecting the strength of the pile, noise pollution of the surrounding environment, damage to the integrity of the pile, etc., and achieve a wide range of product adaptability , The effect of ensuring the lifting strength and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

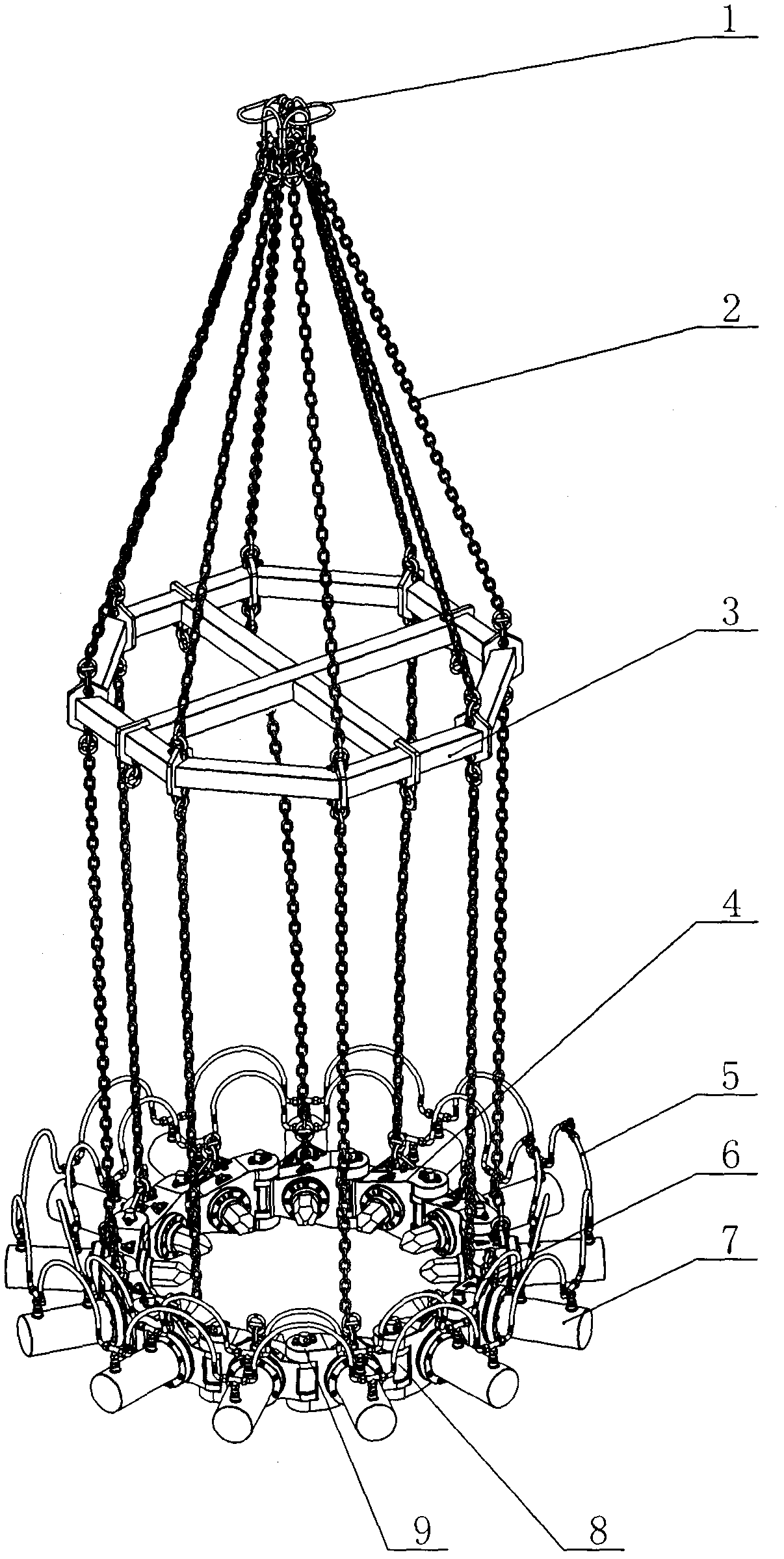

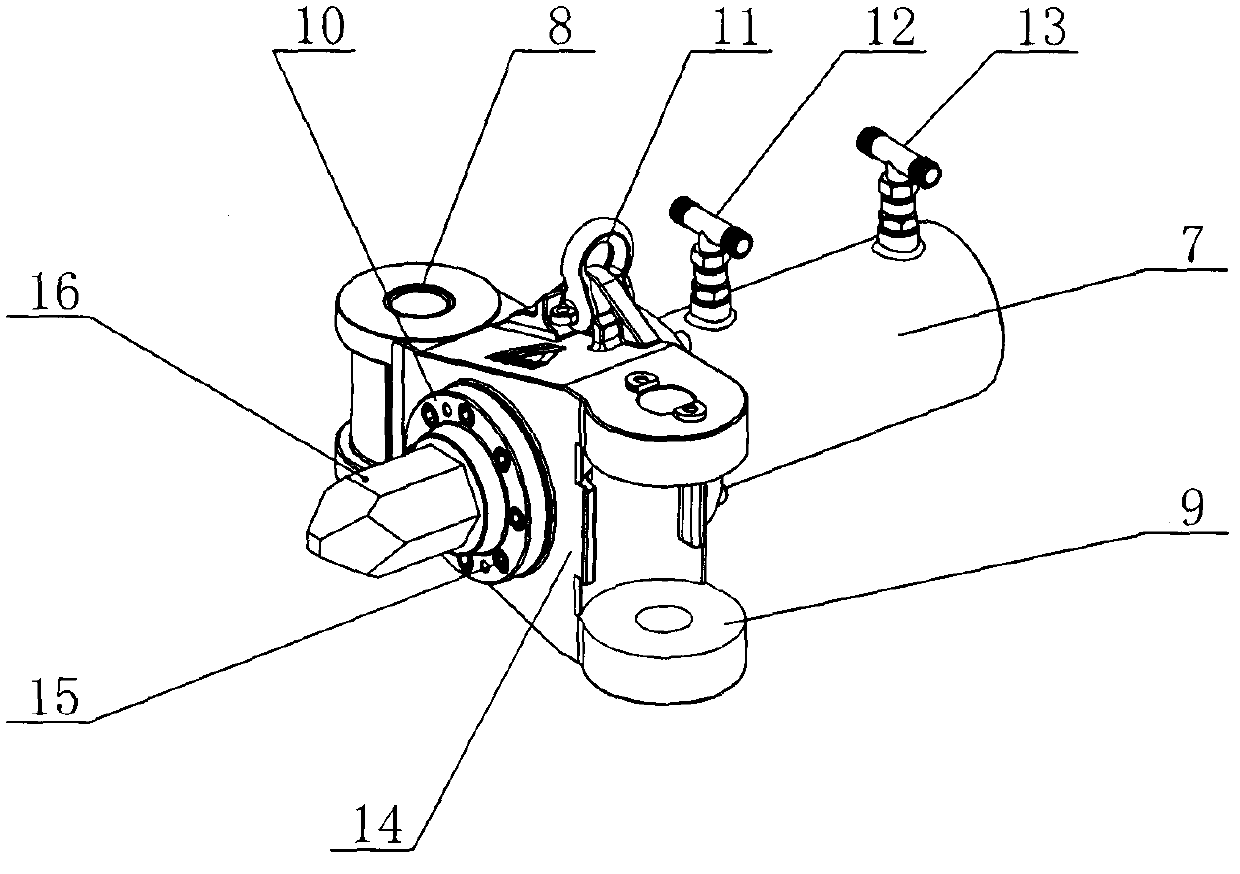

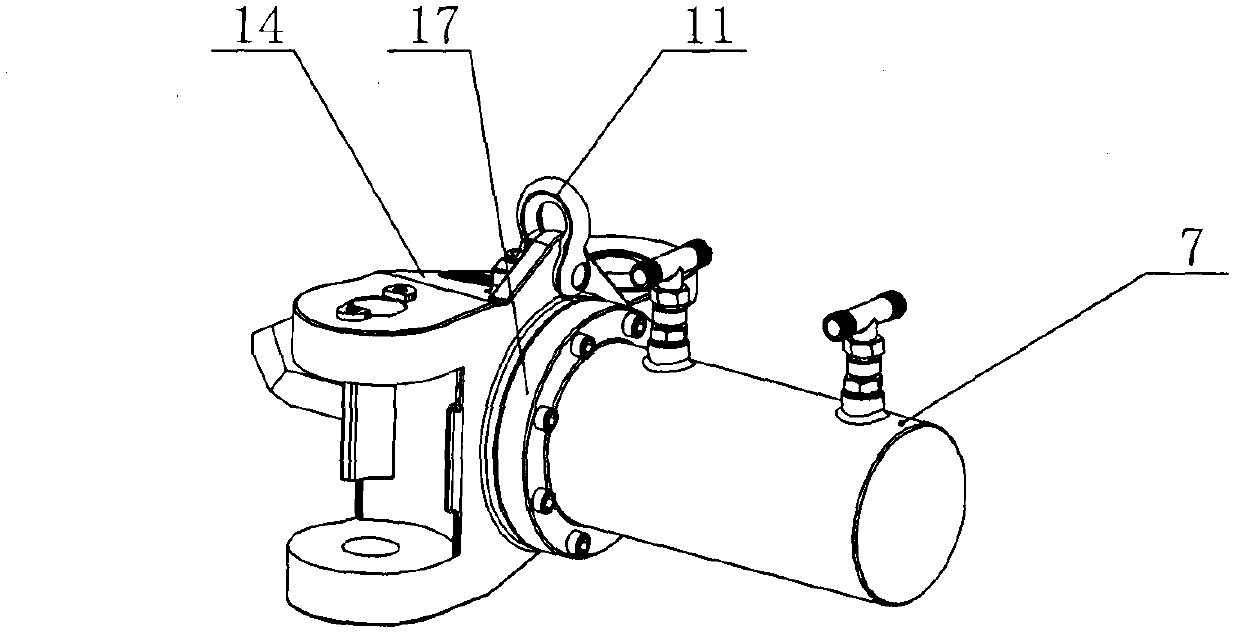

[0018] exist figure 1 Middle: The suspension chain assembly 1 is composed of eight chains 2 in the shape of a pagoda. The eight chains 2 are evenly distributed on the hanger 3. The hanger 3 is octagonal and welded with steel pipes. The hanger The center of 3 is provided with a cross support, the chain 2 on the hanger 3 is connected to the hanging chain ring 11 on the lower end drill rod device 4, and the upper and lower holes of the connection seat B8 and the connection seat A9 are provided with oil-free bearings. The connecting seat B8 is connected with the connecting seat A9 on each drill rod device 4 and fixed with the connecting seat pin 6 to form a circular shape. The oil cylinder 7 of each drill rod device 4 is provided with an oil inlet pipe 12 and an oil outlet pipe 13. The oil inlet pipe 12 and the oil inlet pipe 12 on each chisel device 4 are connected to each other with the hydraulic oil pipe 5, and the oil outlet pipe 13 and the oil outlet pipe 13 are also connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com