Internal reflective vacuum heat collector, forming device and close-packed heat collector

A vacuum heat collecting tube and forming device technology, which is applied in heating devices, solar thermal devices, forming tools, etc., can solve the problems of large heat capacity, light leakage, and water storage in heat collecting tubes, and achieve the effect of small heat capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

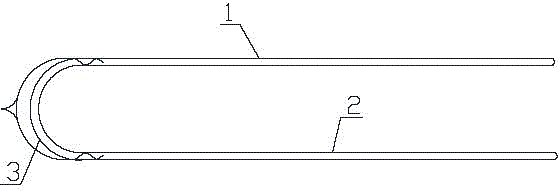

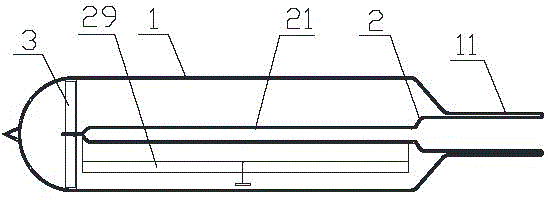

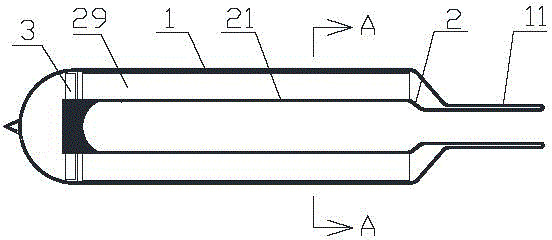

[0042] Such as figure 2 , image 3 with Figure 4 As shown, an internally reflective vacuum heat collecting tube of the present invention includes an outer tube 1, an inner tube 2 and a retaining spring 3, the inner tube 2 fits inside the outer tube 1, and the outer surface of the inner tube is coated with non- White selective light-to-heat conversion coating, the circlip 3 is arranged between the outer tube 1 and the inner tube 2 and is located at the tail end of the inner tube 2, the top ends of the outer tube 1 and the inner tube 2 are welded and sealed, and the outer The interlayer between the tube 1 and the inner tube 2 is a vacuum, and also includes a reflector 29. The diameter of the front section of the outer tube 1 is smaller than the diameter of the rear section to form a reduced diameter section 11, and the inner tube 2 is in the corresponding reduced diameter section of the outer tube 1. Below 11 is a flat tube 21, the reflector 29 is arranged in the interlayer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com