Novel principle and method for measuring diffusion coefficient of hydrogen in metal melt

A metal melt and diffusion coefficient technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as complicated operation and difficulty in obtaining hydrogen diffusion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

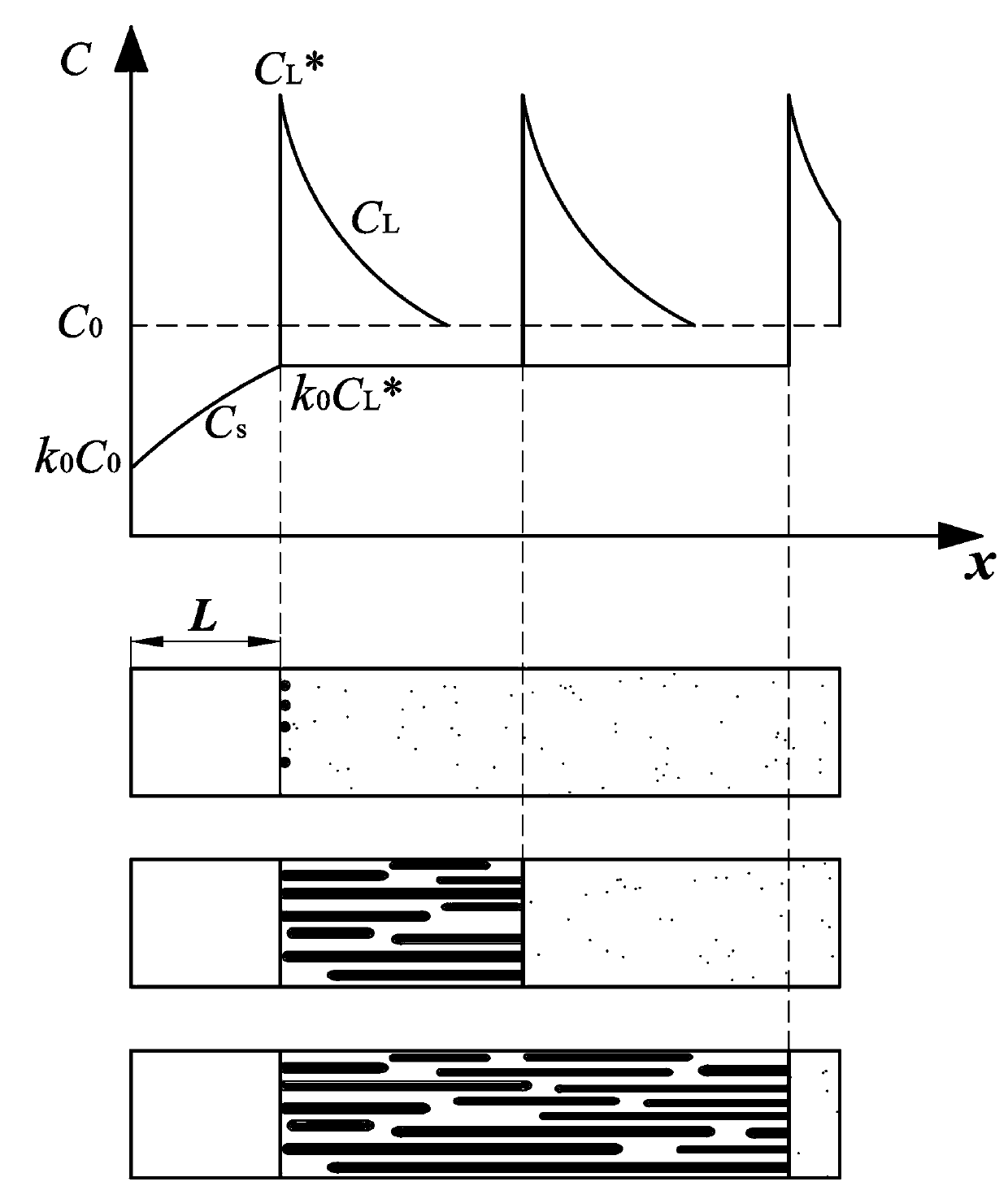

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

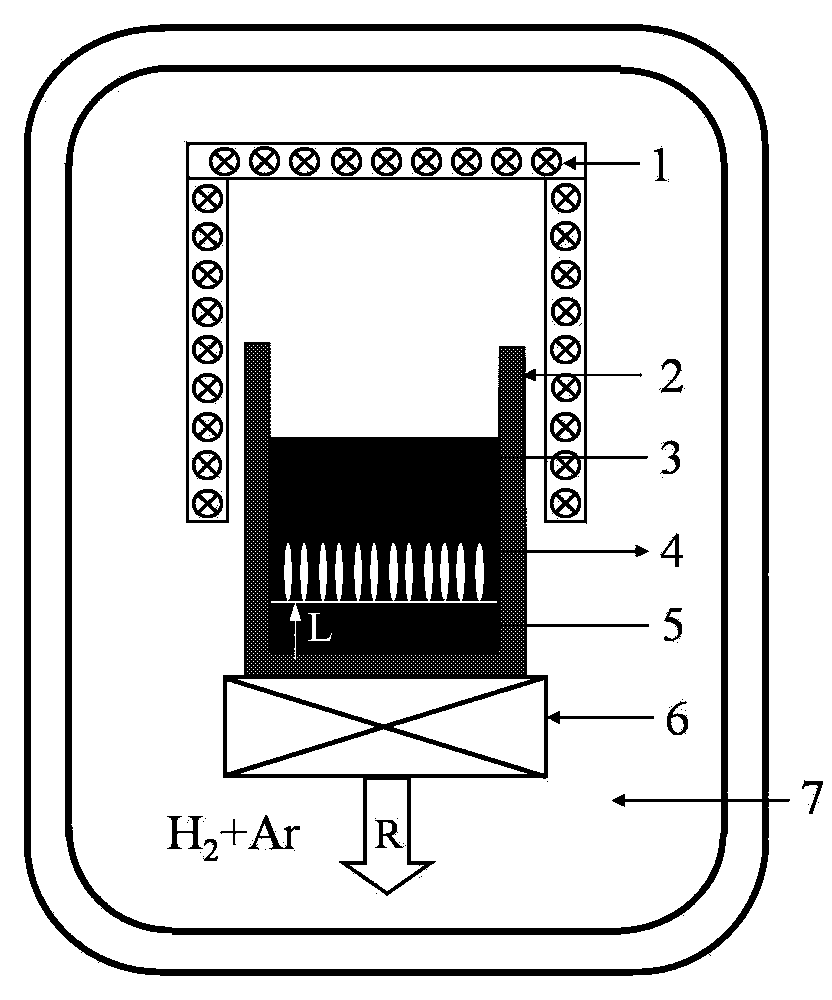

[0040] (1) Prepare a metallic copper sample with a certain thickness of initially solidified non-bubble layer

[0041] Put a certain quality of pure copper (99.99%) into the crucible down-moving vacuum induction melting furnace and vacuumize. Heat the copper material to about 1400K (overheating 50K), fill it with 1×10 5 Pa hydrogen and 5×10 5 Argon gas of Pa, after holding for a period of time, put the crucible in contact with the water-cooled copper bottom to achieve directional solidification, and then cool down and take samples. Use the wire cutting method to cut the sample along the longitudinal section, and measure the initial bubble-free layer thickness L of the porous copper sample to be about 5mm, as shown in the attached image 3 shown.

[0042] (2) Calculate the diffusion coefficient of hydrogen near the melting point of metallic copper

[0043] Calculate the initial hydrogen concentration in the melt:

[0044] C 0 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com