Method for preparing semi-solid slurry or billet of near-eutectic aluminum-silicon alloy

A technology of semi-solid slurry and aluminum-silicon alloy, which is applied in the field of preparation of semi-solid slurry or blank of near-eutectic aluminum-silicon alloy, which can solve the problem of narrow solidification range of aluminum-silicon binary eutectic point, semi-solid slurry or blank Preparation difficulties and other issues, to achieve the effect of large market promotion value, good surface quality, and simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

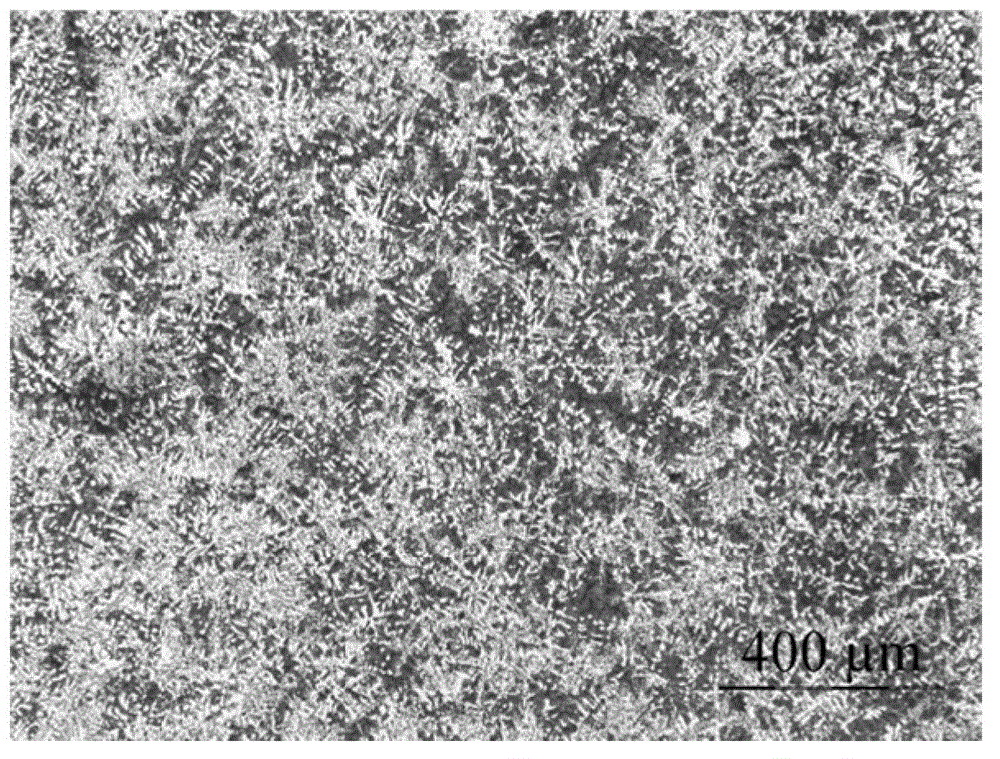

Embodiment 1

[0032] This embodiment relates to a method for preparing a semi-solid slurry of a near-eutectic aluminum-silicon alloy; the method includes the following steps:

[0033] Step 1. Preheat the Japanese brand ADC12 aluminum-silicon alloy produced by Runhui Metal Materials Co., Ltd., whose liquidus temperature is 570-580°C, at a temperature of 100-200°C for 1 hour;

[0034] Step 2, take the aluminum-silicon alloy and add it to the crucible resistance furnace, after the ADC12 aluminum-silicon alloy is melted, let it stand still to obtain the alloy liquid;

[0035] Step 3, take Hongguang HGJ-1 refining agent for refining, add it to the alloy liquid, stir and remove the slag, let it stand for 5-10 minutes, and adjust the temperature of the alloy liquid so that the temperature is 20°C to 50°C higher than the alloy liquidus temperature ℃;

[0036] Step 4. Preheat the mechanical roller coated with casting aluminum alloy coating of Weifang Huashi Casting Materials Co., Ltd. at 250-300°C....

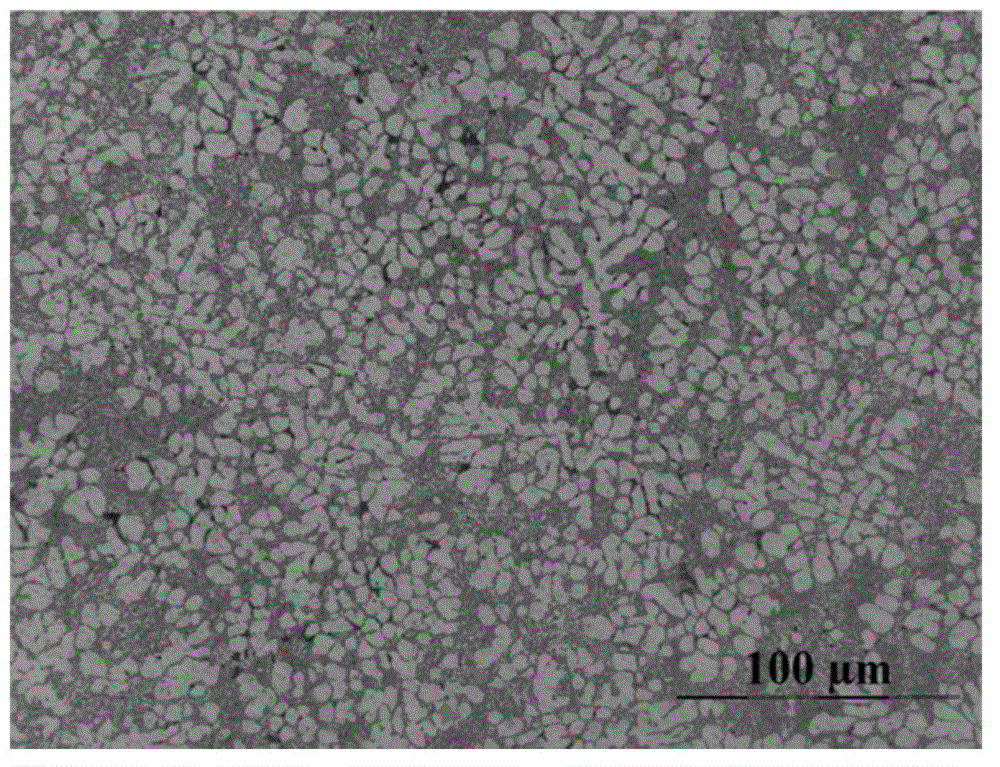

Embodiment 2

[0038] This embodiment relates to a method for preparing a semi-solid slurry of a near-eutectic aluminum-silicon alloy; the method includes the following steps:

[0039] Step 1. Preheat the Japanese brand ADC12 aluminum-silicon alloy produced by Runhui Metal Materials Co., Ltd., whose liquidus temperature is 570-580°C, at a temperature of 100-200°C for 1 hour;

[0040] Step 2, take the aluminum-silicon alloy and add it to the crucible resistance furnace, after the ADC12 aluminum-silicon alloy is melted, let it stand still to obtain the alloy liquid;

[0041] Step 3, take Hongguang HGJ-1 refining agent for refining, add it to the alloy liquid, stir and remove slag, let stand for 5-10 minutes,

[0042] Adjust the temperature of the alloy liquid to 620°C;

[0043] Step 4, preheat the mechanical roller coated with the casting aluminum alloy coating of Weifang Huashi Casting Materials Co., Ltd. at 250-300°C; the aluminum alloy casting coating used in this example belongs to the co...

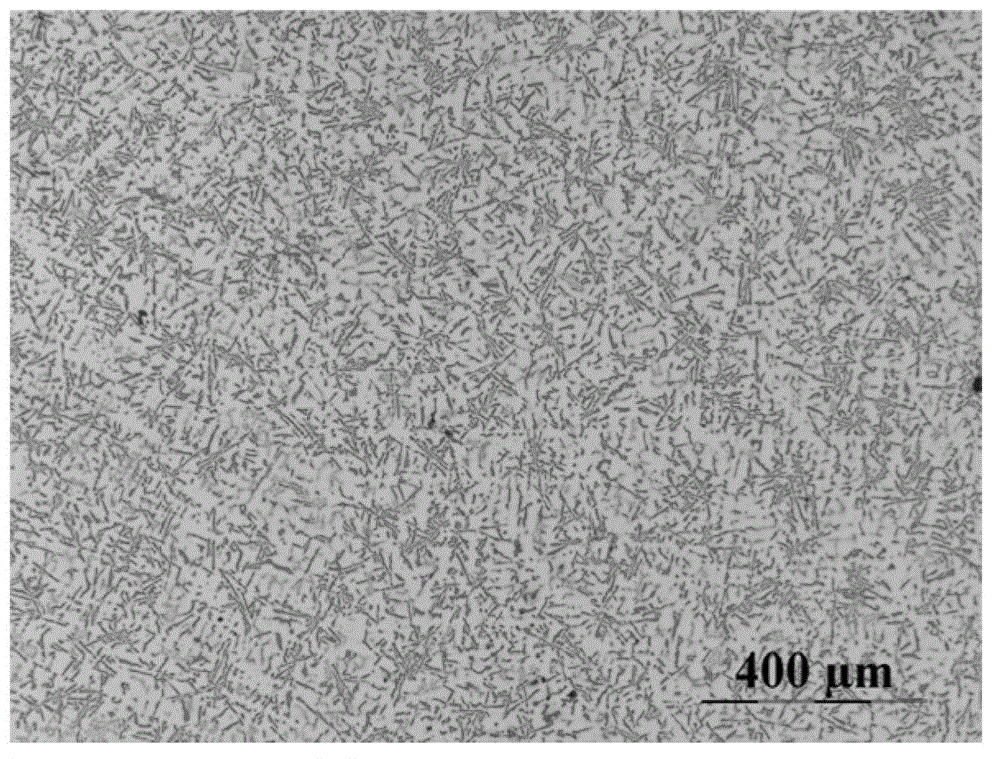

Embodiment 3

[0045] This embodiment relates to a method for preparing a semi-solid blank of a near-eutectic aluminum-silicon alloy; the method includes the following steps:

[0046]Step 1. Preheat the Japanese brand ADC12 aluminum-silicon alloy produced by Runhui Metal Materials Co., Ltd., whose liquidus temperature is 570-580°C, at a temperature of 100-200°C for 1 hour;

[0047] Step 2, take the aluminum-silicon alloy and add it to the crucible resistance furnace, after the ADC12 aluminum-silicon alloy is melted, let it stand still to obtain the alloy liquid;

[0048] Step 3, take Hongguang HGJ-1 refining agent for refining, add it to the alloy liquid, stir and remove slag, let it stand for 5-10 minutes, and adjust the temperature of the alloy liquid to 620°C;

[0049] Step 4, preheat the mechanical roller coated with casting aluminum alloy coating of Weifang Huashi Casting Materials Co., Ltd. at 250-300°C; the aluminum alloy casting coating used in this example belongs to the common know...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com