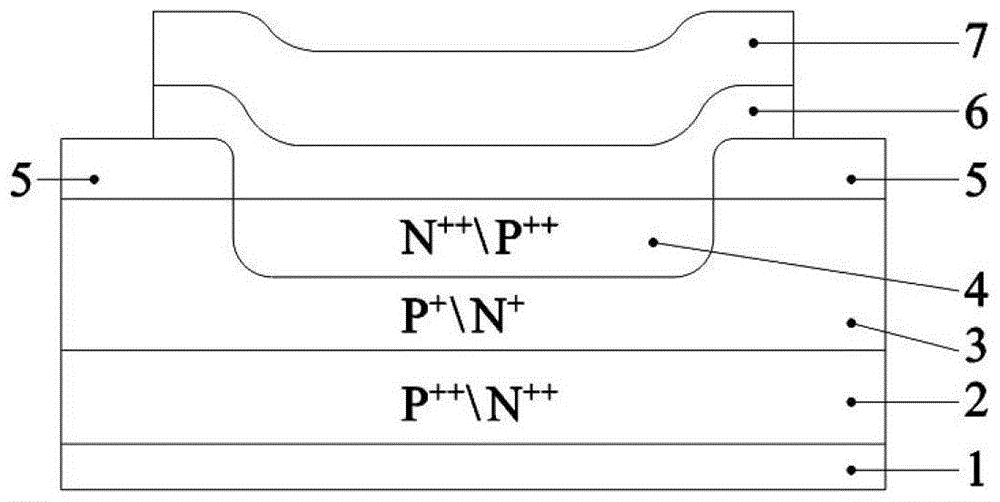

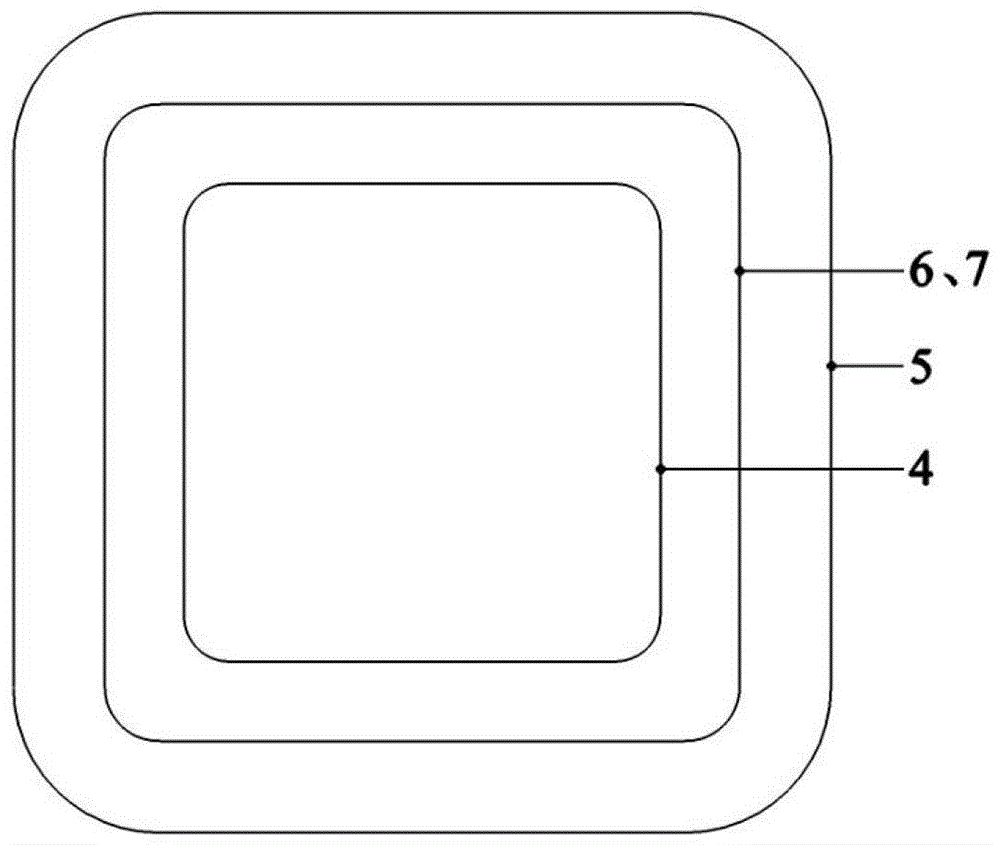

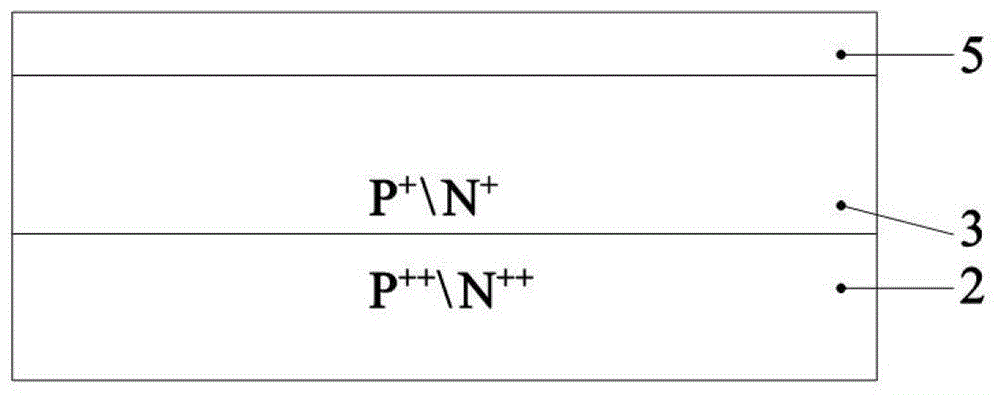

A kind of low voltage diode and its manufacturing method

A manufacturing method and diode technology, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve problems such as increased formation defects and poor performance of diodes, so as to simplify the process, improve production efficiency, and reduce unstable product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0067] Using the above-mentioned manufacturing method, make a size of 0.2×0.2mm, the reverse breakdown voltage is 5.8V≤VR≤7.6V, when VR=5V, the leakage current IR≤100nA, can discharge the surge current Ipp ≥10A, low voltage diode with antistatic level up to 8kV. In this diode, the doping type of the epitaxial region is P-type, the resistivity is about 0.015-0.02Ω·cm, the thickness is about 6 μm, the doping type of the inverse doping active region is N-type, and the doping dose is about 1× 10 15 cm -2 , with a depth of about 1 μm. The material of the front metal electrode layer is aluminum, and the interlayer protective layer is a nickel-chromium metal layer with a thickness of 1.5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com