Feeding attractant for piglets and production method thereof

A feed attractant, piglet technology, applied in the application, animal feed, animal feed and other directions, to achieve the effect of simplifying control methods, promoting appetite, and increasing concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This example describes the method for culturing the microorganisms used in the present invention.

[0051] 1. Culture of Lactobacillus delbrueckii subsp. bulgaricus:

[0052] 1-1. Activation of strains: use an inoculation needle to take a loop of strains and insert them into 5 mL of activated medium. The composition of the activated medium: 10.0 g of casein peptone, 10.0 g of beef extract, 5.0 g of yeast extract, 5.0 g of glucose, Sodium acetate 5.0g, diamine citrate 2.0g, Tween 80 1.0g, K 2 HPO 4 2.0g, MgSO 4 .7H 2 O 0.2g, MnSO 4 .H 2 O 0.05g, CaCO 3 20.0g, agar 15.0g, distilled water 1.0L, pH 6.8. Sterilize at 121°C for 20 minutes; place in a biochemical incubator at 43°C for static culture for 16 hours.

[0053] 1-2. Strain culture for fermentation: Take 5mL of activated strains and put them into 100mL of seed medium. The composition of seed medium: 30g of soybean meal, 10g of glucose, 1.0L of distilled water, natural pH, sterilized at 115°C 20 minutes. It...

Embodiment 2

[0058] This example describes a preferred production method of the food attractant.

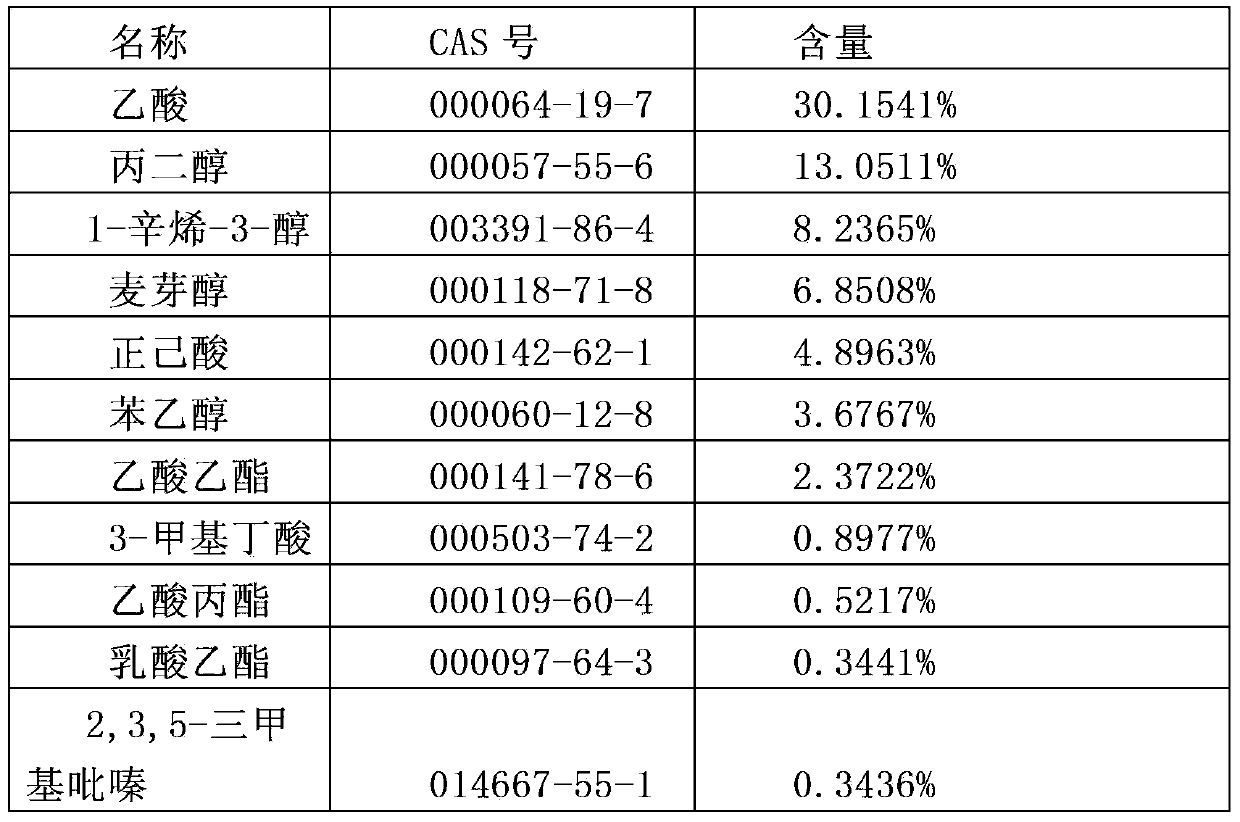

[0059] After mixing 50 parts by weight of soybean meal, 30 parts by weight of glucose, and 20 parts by weight of milk powder, add warm water at 38 ° C to make the water content of the mixture at 40%, add 10% (v%, refer to solids (soybean meal, Saccharomyces cerevisiae cultivated in step 2 of seed solution = w: v%), incubated for 16 hours, and 30% (v%) of the lactic acid bacteria cultivated in step 1 were connected to solids (soybean meal, Glucose and milk powder): seed solution = w: v%), incubated at 43°C for 60 hours. After the cultivation, the materials are dried with a vibrating fluidized bed, and a tubular cooler is used for the water evaporated during the drying process (the design standard of the cooler: the inlet temperature is 115°C, and the outlet temperature is adjustable at 50-90°C) Cool, collect the cooling liquid cooled by the cooler, filter and concentrate the cooling liquid th...

Embodiment 3

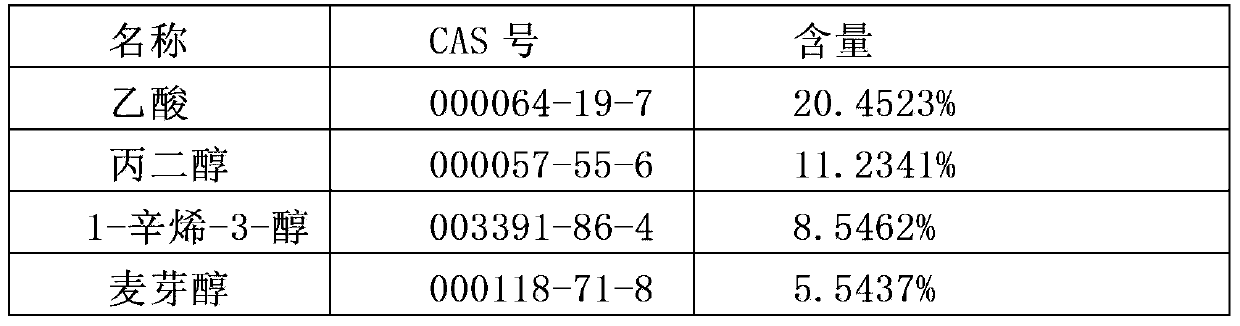

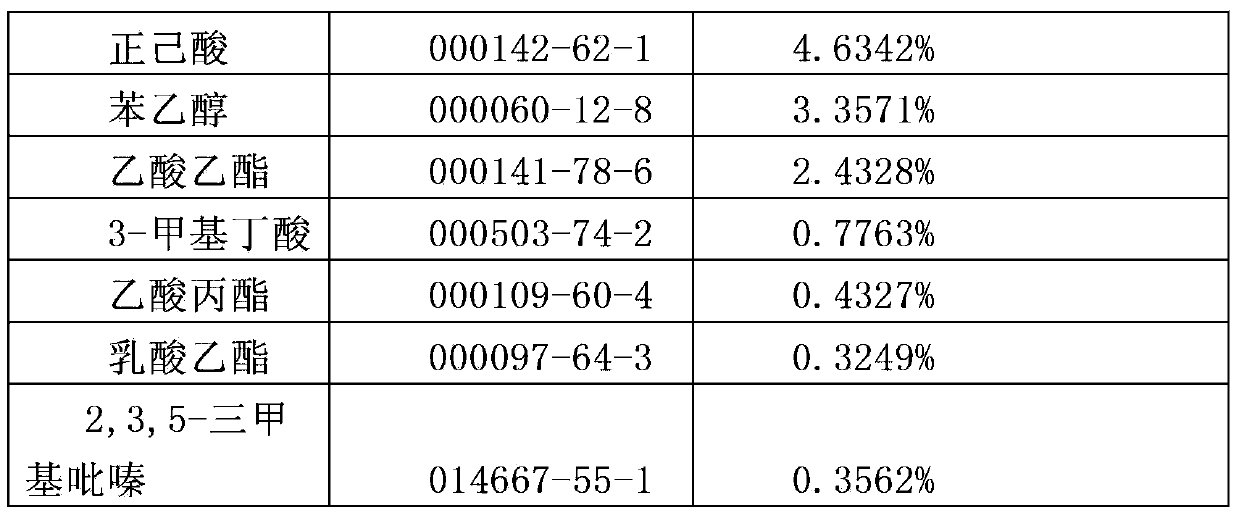

[0063] This example describes a preferred production method of the food attractant.

[0064] After mixing 80 parts by weight of soybean meal, 10 parts by weight of glucose, and 10 parts by weight of milk powder, add warm water at 38 ° C to make the water content of the mixture at 60%, add 10% (v%, refers to solids (soybean meal, Saccharomyces cerevisiae cultivated in step 2 of seed solution = w: v%), incubated at rest for 16 hours, and connected to 2% (v%) of lactic acid bacteria cultivated in step 1, referring to solids (soybean meal, Glucose and milk powder): seed solution = w: v%), incubated at 43°C for 60 hours. After the cultivation, the materials are dried with a vibrating fluidized bed, and a tubular cooler is used for the water evaporated during the drying process (the design standard of the cooler: the inlet temperature is 115°C, and the outlet temperature is adjustable at 50-90°C) Cooling, collecting the cooling liquid cooled by the cooler, filtering and concentrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com