A kind of fermented compound feed of seed melon rind and its preparation method

A compound feed, seed melon rind technology, applied in the field of livestock and poultry feed resources development, can solve the problems of destroying the ecological balance of farmland, waste of resources, discarding, etc., and achieve significant effects and feed utilization, and the effect of enriching amino acids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]Example 1: Preparation of Fermented Compound Feed with Seed Melon Skin and Pulp

[0036] Select fresh non-rotten seed melon rind, crush the seed melon rind into 1-2mm particles, beat the seed melon pulp, and set aside; grind dry wheat straw to 2-3mm, and crush soybean meal to 200-300μm for later use; bacterial agent preparation: average the number of live bacteria for 10 6 —10 7 Lactobacillus acidophilus, Saccharomyces cerevisiae and Bacillus subtilis are activated and mixed according to the weight ratio of 1:1:1 to prepare the fermentation agent; inoculation and fermentation: prepare the prepared seed melon husk, dried wheat straw and soybean meal in a weight ratio of 7:2 : Mix in a ratio of 1, sprinkle into the fermentation agent according to the weight ratio of 2%, fully stir and evenly mix the fermentation raw materials, and then put it into a fermentation bag with an amount of 30Kg / bag, and step on it once for each 20cm height, and seal it. For each group, do 3 gr...

Embodiment 2

[0052] Example 2: Evaluation of the quality and effectiveness of fermented compound feed with different preparation process parameters

[0053] See Table 5 for the evaluation of the quality and effectiveness of the fermented compound feed with seeds and melon peel and pulp under the implementation of the above-mentioned Example 1.

[0054] Table 5: Efficacy Scoring Criteria (Full Score 30 Points)

[0055]

[0056] Note: The total score is the sum of the scores of each indicator

[0057] Response surface method optimized formula, test factors and levels are shown in Table 6:

[0058] Table 6: Table of Factors and Levels of Response Surface Test

[0059]

[0060] Table 7: Response Surface Experiment Design and Results

[0061]

[0062]

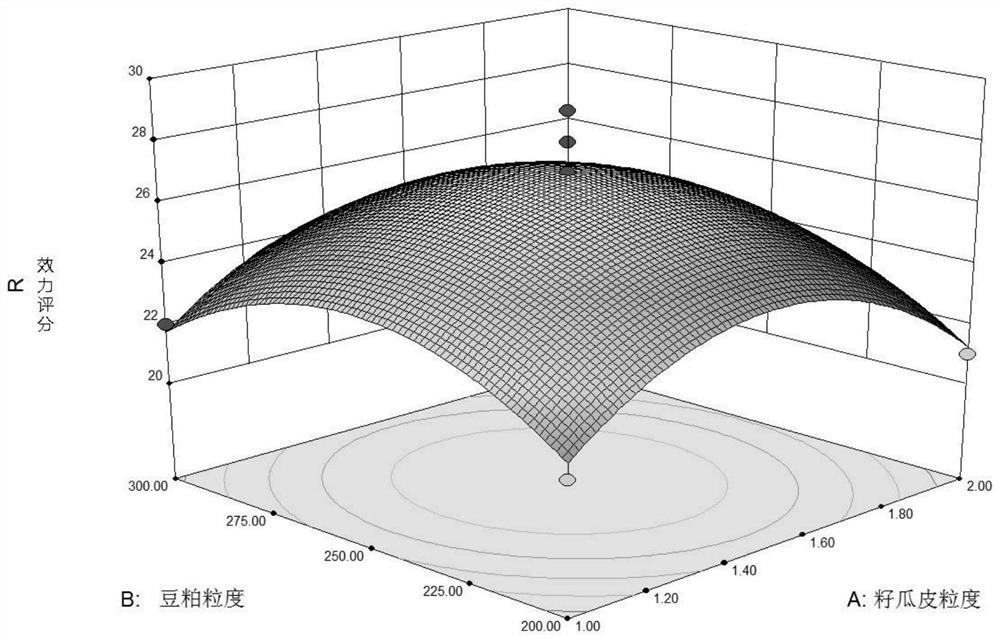

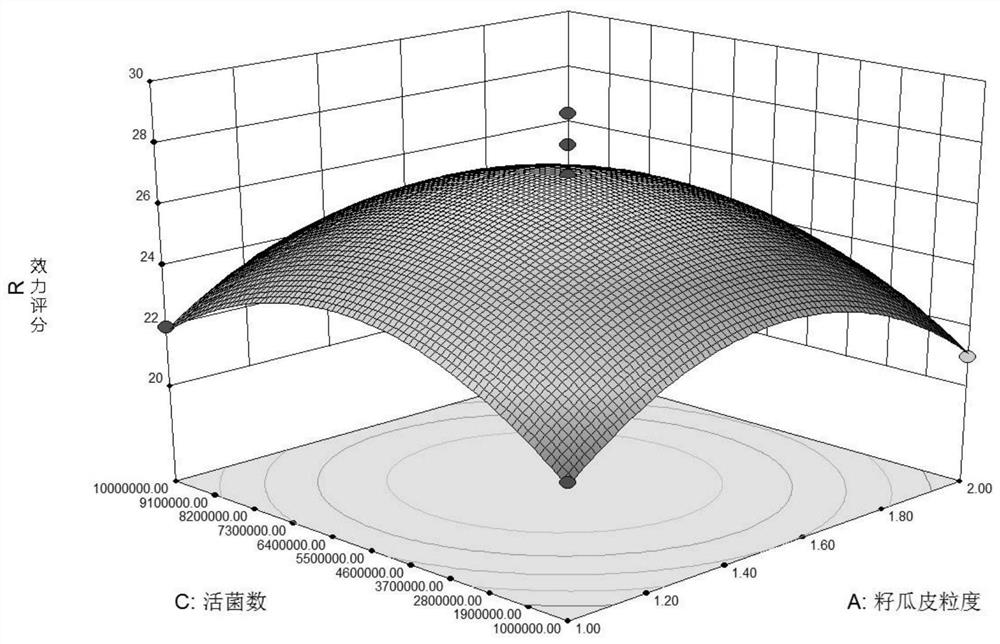

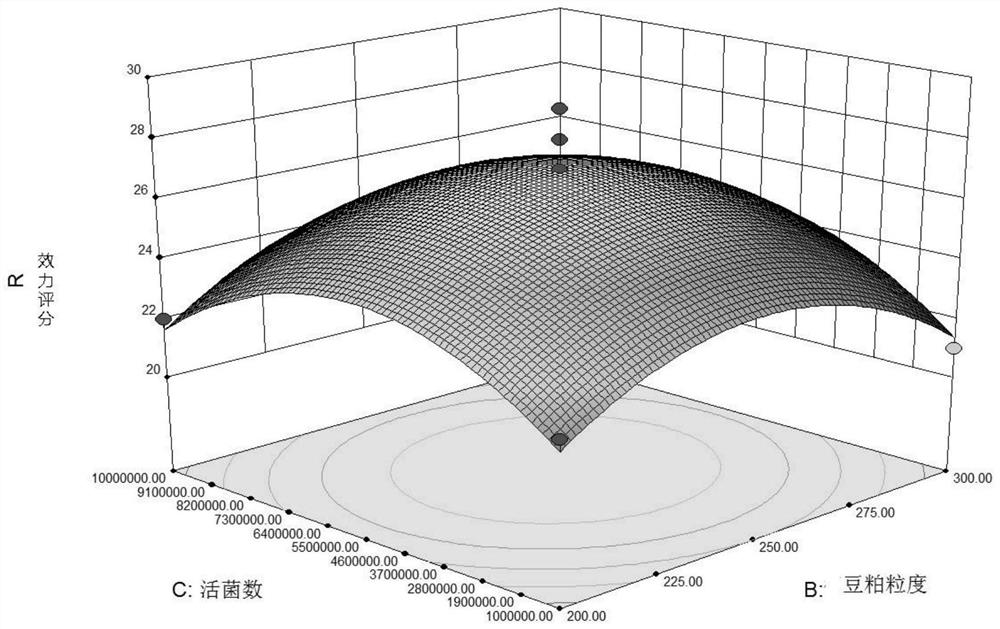

[0063] Response Surface Experiment Design and Results:

[0064] According to the Box-Benhnken central combination design principle, the experimental design analysis is carried out, and the results are shown in Table 7. The exper...

Embodiment 3

[0067] Example 3: Feeding Effect of Fermented Compound Feed with Seed Melon Skin and Pulp

[0068] Based on the fermented compound feed of seeds and melon pulps implemented in Example 1, it was added to the diet at a ratio of 5% to feed sheep. The sheep breed in this experiment is Xinjiang fine-wool sheep, aged 120 days, passed the 60-day feeding experiment, the daily gain (g) was 101.8+28.9, the daily feed intake was 1554.8+153, and the daily dry matter intake was 716.9+79.5 , feed efficiency 15.3+5.3, dry matter feed efficiency 7.0+2.7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com