Method and device for fitting touch control display panel

A technology for touch display panels and bonding devices, which is applied in lamination devices, chemical instruments and methods, instruments, etc., and can solve problems affecting the production capacity of bonding processing, high defect rate, and inability to cover side areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

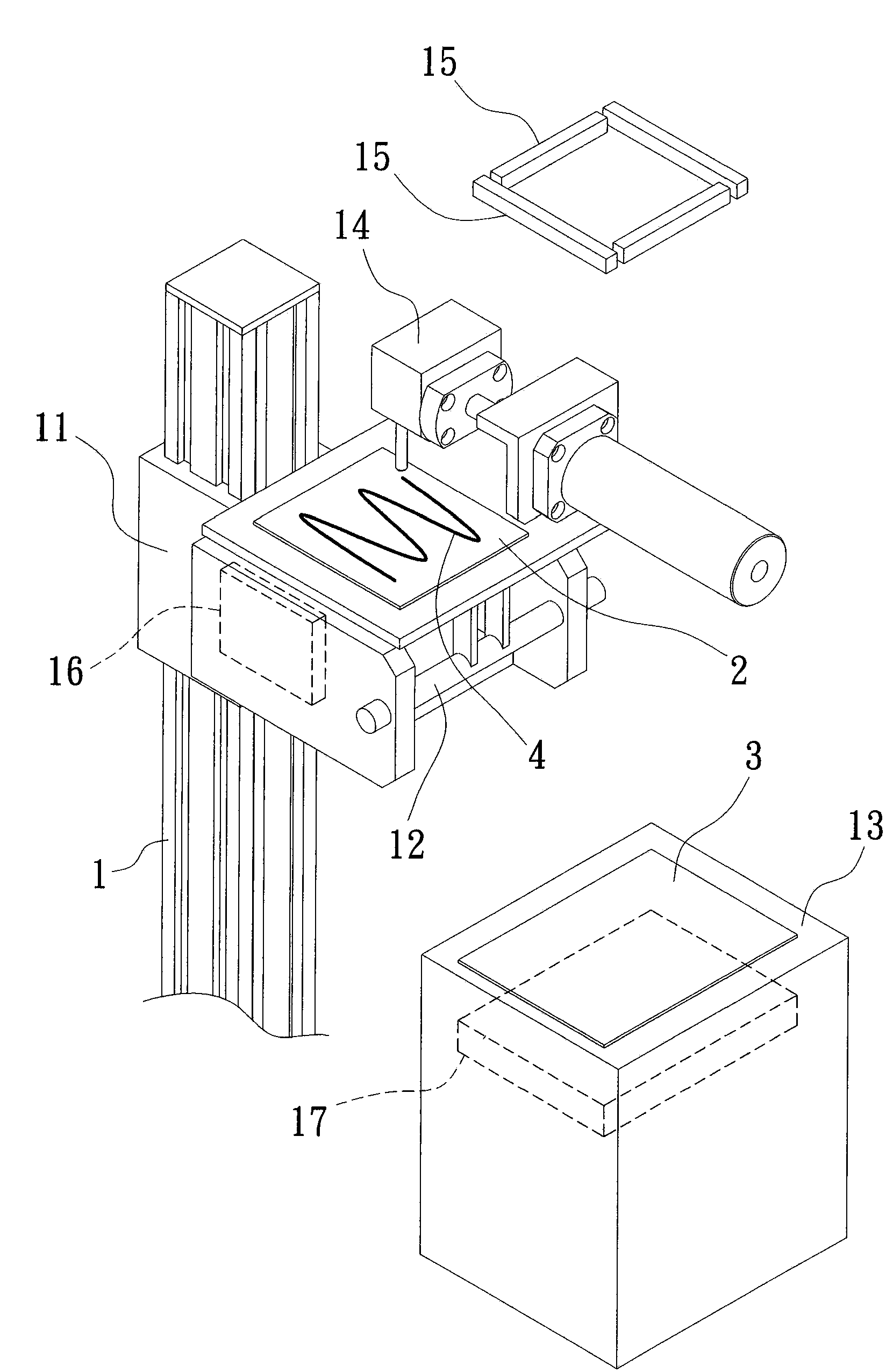

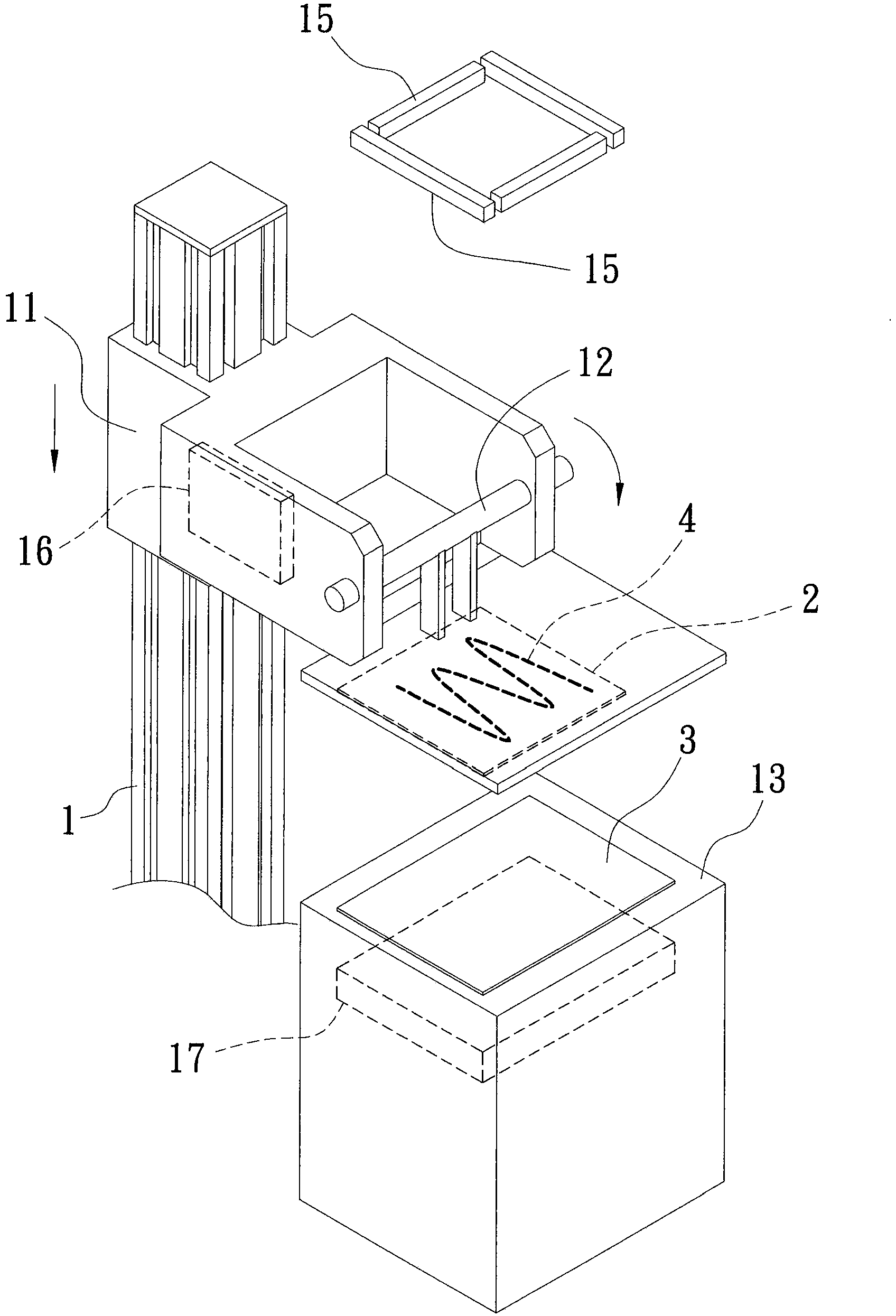

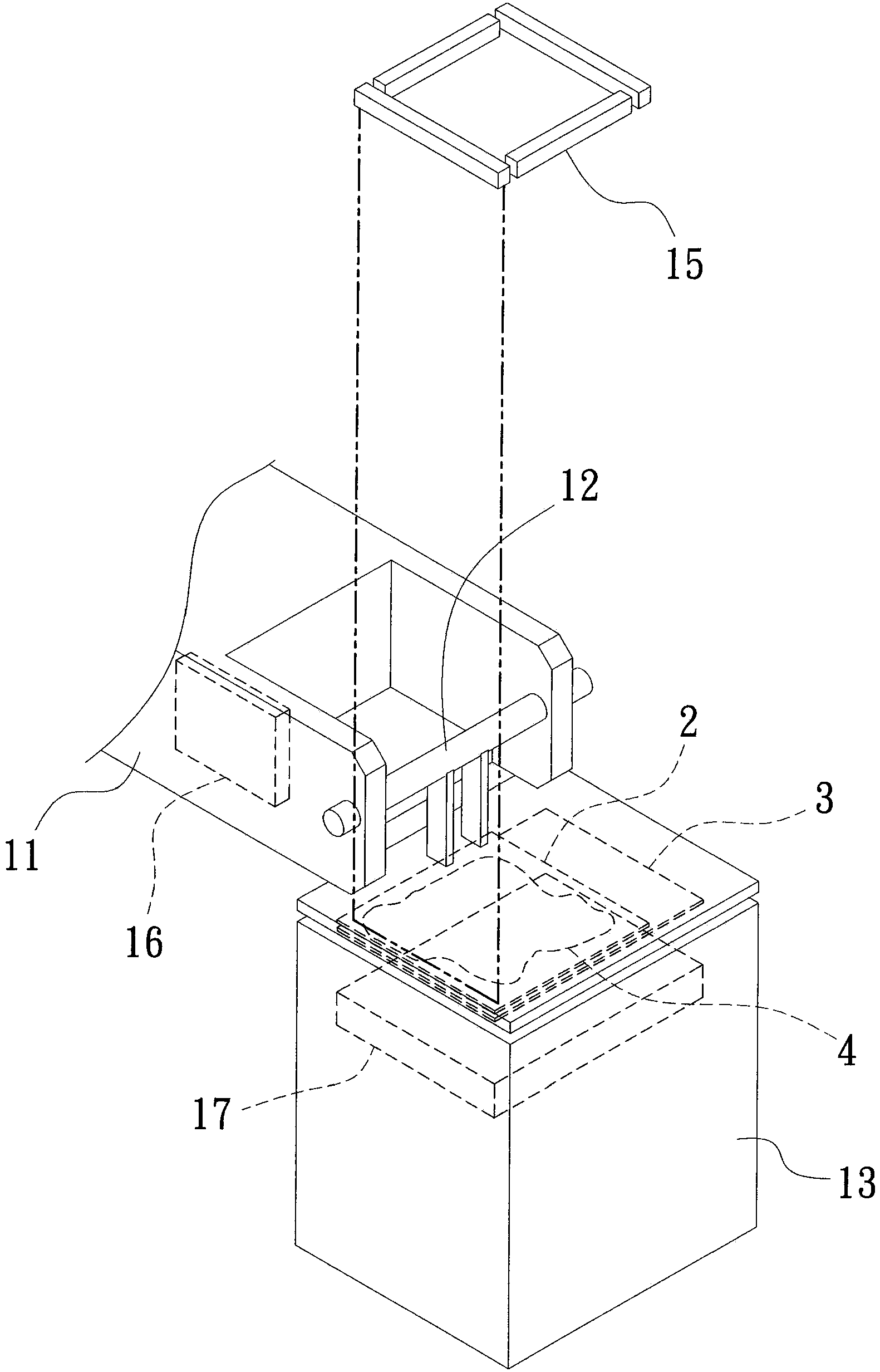

[0031] First, see figure 1 As shown, it is a preferred embodiment of the touch display panel bonding device of the present invention, which mainly includes:

[0032] a base 1;

[0033] A lifting device 11, set on the base 1;

[0034] A first positioning mechanism 12 is pivotally arranged on the lifting device 11, and a first workpiece 2 is fixed on it through the first positioning mechanism 12; wherein, the first positioning mechanism 12 can fix the first workpiece 2 on it by vacuum adsorption superior;

[0035] A second positioning mechanism 13 is arranged on the base 1, and a second workpiece 3 is fixed on it through the second positioning mechanism 13; wherein, the second positioning mechanism 13 can also fix the second workpiece 3 on it by means of vacuum adsorption. Above, the procedure for adjusting the alignment with the first workpiece 2;

[0036] A coating mechanism 14 is arranged on the base 1, and the coating mechanism 14 can coat the adhesive material 4 on a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com