Backing brick for coal water slurry pressurized gasifier and preparation method of backing brick

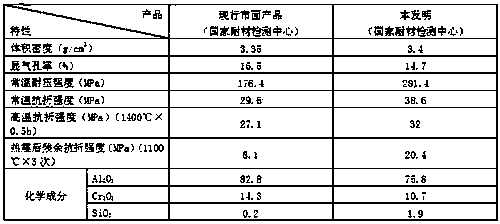

A technology of pressurized gasification and coal-water slurry, applied in the field of refractory materials, can solve the problems of low service life and poor thermal shock resistance, and achieve the effects of prolonging service life, improving strength and thermal shock resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A backing brick for a coal-water slurry pressurized gasifier, which is composed of a material and a binder with a weight of 2% of the material. The material is made of chrome corundum material with a particle size of less than 5mm, and α-Al with a particle size of less than 240 mesh 2 o 3 Micropowder, siliceous material with particle size less than 180 mesh and chromium oxide green are mixed, and the amount of chrome corundum material in the material is 80%, α-Al 2 o 3 The amount of fine powder is 12%, the amount of siliceous material is 5%, and the amount of chromium oxide green is 3%.

[0021] The preparation method of the backing brick for the coal-water slurry pressurized gasifier is as follows:

[0022] 1) According to the above requirements, select and weigh the binder, chrome corundum material, α-Al 2 o 3 powder, siliceous material and chromium oxide green, and then the weighed α-Al 2 o 3 Micropowder, siliceous material and chromium oxide green were mixed f...

Embodiment 2

[0026] A backing brick for a coal-water slurry pressurized gasifier, which is composed of a material and a binder with a weight of 4.5% of the material. The material is made of chrome corundum material with a particle size of less than 5mm and α-Al with a particle size of less than 240 mesh 2 o 3 Micropowder, siliceous material with particle size less than 180 mesh and chromium oxide green are mixed, and the amount of chrome corundum material in the material is 90%, α-Al 2 o 3 The amount of fine powder is 8%, the amount of siliceous material is 1%, and the amount of chromium oxide green is 1%.

[0027] The preparation method of the backing brick for the coal-water slurry pressurized gasifier is as follows:

[0028] 1) According to the above requirements, select and weigh the binder, chrome corundum material, α-Al 2 o 3 powder, siliceous material and chromium oxide green, and then the weighed α-Al 2 o 3 Micropowder, siliceous material and chromium oxide green were mixed f...

Embodiment 3

[0032] A backing brick for a coal-water slurry pressurized gasifier, which is composed of a material and a binder with a weight of 3% of the material. The material is made of chrome corundum material with a particle size of less than 5mm, and α-Al with a particle size of less than 240 mesh 2 o 3 Micropowder, siliceous material with a particle size of less than 180 meshes and chromium oxide green are mixed, and the amount of chrome corundum material in the material is 85%, α-Al 2 o 3 The amount of fine powder is 10%, the amount of siliceous material is 3%, and the amount of chromium oxide green is 2%.

[0033] The preparation method of the backing brick for the coal-water slurry pressurized gasifier is as follows:

[0034] 1) According to the above requirements, select and weigh the binder, chrome corundum material, α-Al 2 o 3 powder, siliceous material and chromium oxide green, and then the weighed α-Al 2 o 3 Micropowder, siliceous material and chromium oxide green were ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com