Organic fertilizer and production method thereof

An organic fertilizer and mixing technology, which is applied in the direction of organic fertilizer, organic fertilizer preparation, bio-organic part treatment, etc., can solve the problems of tobacco leftovers turning waste into treasure, polluting the environment, etc., and achieve the suppression of disease transmission, simple operation, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] This example prepares 1000 kilograms of fertilizers, including 100 kilograms of tobacco leftovers, 899 kilograms of livestock manure, wherein the water content is 35%, and 1 kilogram of silicate bacterial agent. The production method is as follows: 1) Tobacco crushing: crushing the tobacco waste into pieces below 5mm; 2) Mixing; 3) Turning: Mixing various ingredients in the fermentation tank using a turning machine to make each The ingredients are evenly distributed; 4) Fermentation: The silicate bacterial agent begins to decompose the livestock manure. During the fermentation process, the temperature in the tank rises. When the temperature exceeds 80°C, the mixture is stirred once and the fermentation continues. The duration of fermentation is 12 days, and the fermentation is over; 5) Discharging: When discharging, check whether the moisture meets the requirements.

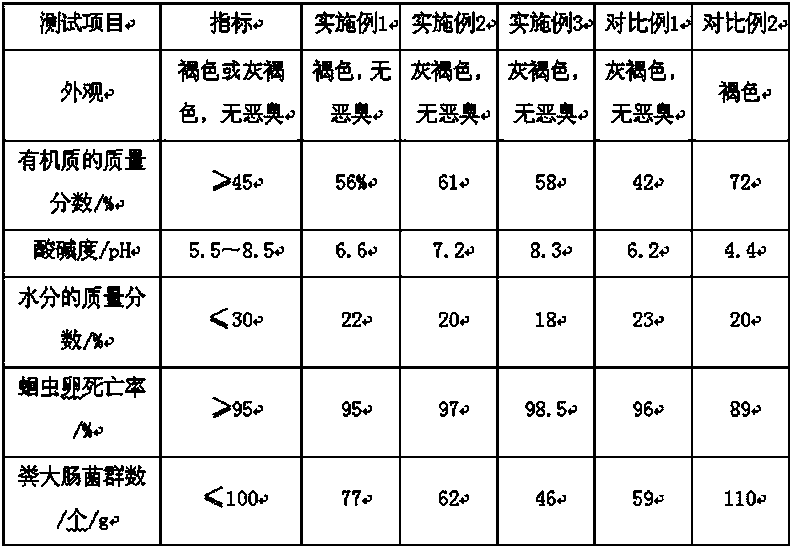

[0023] Product testing, to test parameters such as the appearance of the above-mentioned products, the ...

Embodiment 2

[0032] This example prepares 1000 kilograms of fertilizers, including 150 kilograms of tobacco leftovers, 849 kilograms of livestock manure, wherein the water content is 38%, and 1 kilogram of silicate bacterial agent. The production method is as follows: 1) Tobacco crushing: crushing the tobacco waste into pieces below 5mm; 2) Mixing; 3) Turning: Mixing various ingredients in the fermentation tank using a turning machine to make each The ingredients are evenly distributed; 4) Fermentation: The silicate bacterial agent begins to decompose the livestock manure. When the temperature in the fermentation tank exceeds 80°C, the mixture is stirred once and the fermentation continues. The duration of fermentation is 15 days, and the fermentation is over; 5) Discharging: When discharging, check whether the moisture meets the requirements.

[0033] The above products were tested and the results are summarized in Table 1.

Embodiment 3

[0035] This example prepares 1000 kilograms of fertilizers, including 200 kilograms of tobacco leftovers, 799 kilograms of livestock manure, wherein the water content is 40%, and 1 kilogram of silicate bacterial agent. The production method is as follows: 1) Tobacco crushing: crushing the tobacco waste into pieces below 5mm; 2) Mixing; 3) Turning: Mixing various ingredients in the fermentation tank using a turning machine to make each The ingredients are evenly distributed; 4) Fermentation: The silicate bacterial agent begins to decompose the livestock manure. During the fermentation process, the temperature in the tank rises. When the temperature exceeds 80°C, the mixture is stirred once and the fermentation continues. The duration of fermentation is 18 days, and the fermentation is over; 5) Discharging: When discharging, check whether the moisture meets the requirements.

[0036] The above products were tested and the results are summarized in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com