Preparation method for isomeric alcohol polyoxypropylene polyoxyethylene ether

A technology of propylene polyoxyethylene ether and isomerized alcohol, which is applied in the preparation of ether, the preparation of ether from alkylene oxide, organic chemistry, etc., can solve the problems of easy freezing, increase the cost of online production and processing of factories, and high foam, and achieve excellent emulsification. , excellent penetration and wetting properties, fast drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

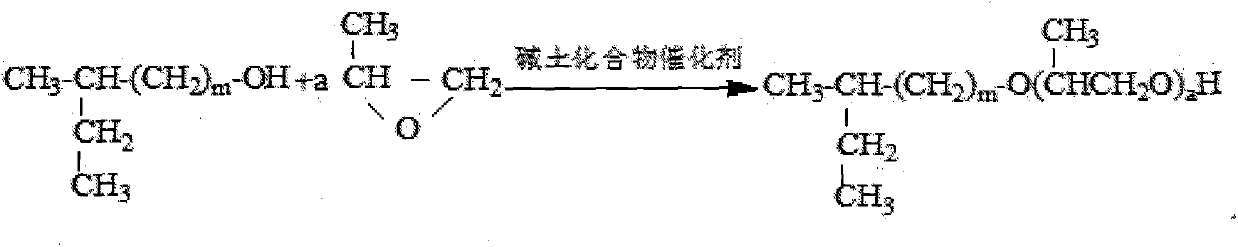

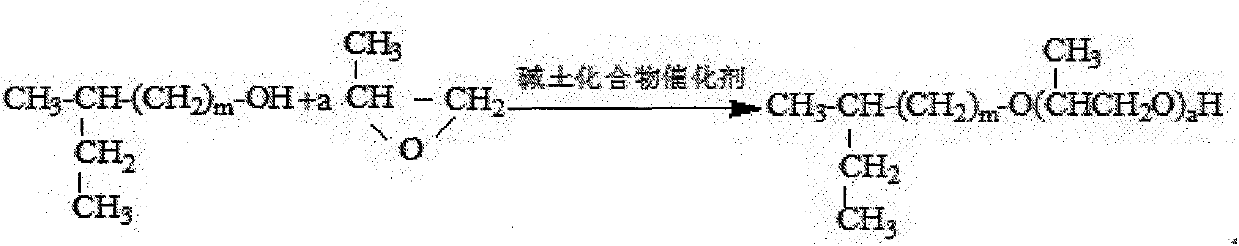

[0019] A preparation method of isomeric alcohol polyoxypropylene polyoxyethylene ether, comprising the following steps: (1) using isomeric alcohol as an initiator, using an alkaline earth metal compound as a catalyst, adding propylene oxide to carry out condensation reaction:

[0020]

[0021] In the reaction equation, m=6, 7, 9; a=1~3, b=3~9.

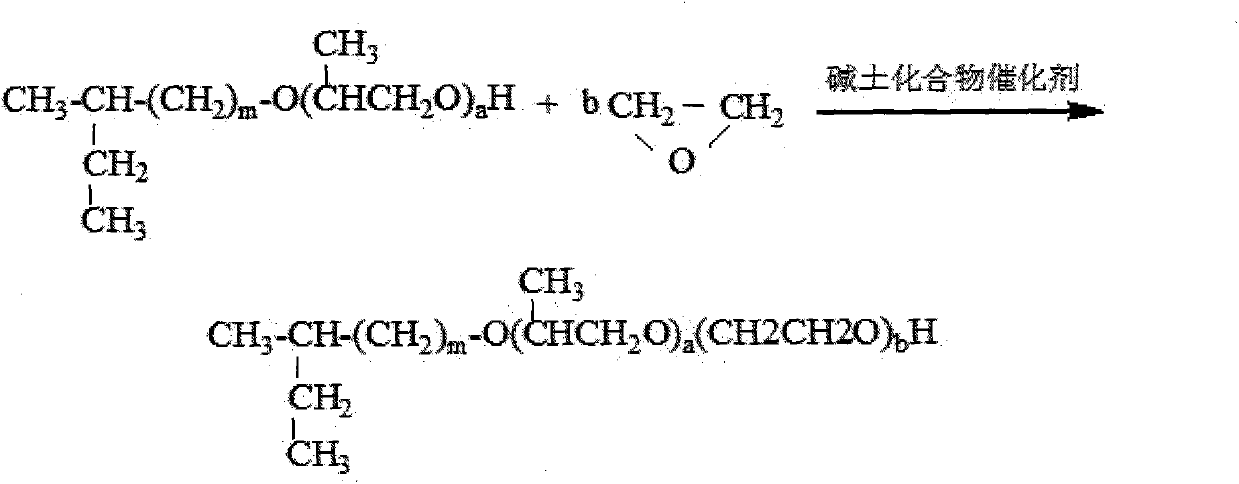

[0022] (2) Then add ethylene oxide and carry out condensation reaction, prepare isomery alcohol polyoxypropylene polyoxyethylene ether:

[0023]

[0024] In the reaction equation, m=6, 7, 9; a=1~3, b=3~9.

[0025] Preferably, the isomeric alcohol is any one of isomeric decanol, isomeric undecyl alcohol and isomeric tridecanol.

[0026] Preferably, the alkaline earth compound catalyst is one or more mixtures of calcium hydroxide, barium hydroxide and magnesium hydroxide.

[0027] Preferably, the added mass of the alkaline earth compound catalyst is 0.1-1.0% of the total mass of isomeric alcohol, propylene oxide and ethylene oxid...

Embodiment 1

[0035] Embodiment 1 Preparation of isomerized undecyl alcohol polyoxypropylene polyoxyethylene ether

[0036] Add 1.0 mol (172 g) of isomeric undecyl alcohol and 2.1 g of barium hydroxide catalyst in the pressure reactor, and connect the propylene oxide metering tank to the pressure reactor. Replace the air in the kettle with nitrogen for 3 times. After the temperature of the kettle rises to 145-150° C., 2 mol (116 g) of propylene oxide is passed through for 1.5 hours, and the reaction is continued for 1.5 hours. After the kettle temperature dropped to 100-105°C, 3 mol (132 g) of ethylene oxide was passed through for 0.5 hour, and the reaction was continued for 0.5 hour. After the reaction was completed, it was cooled and the pressure was released to obtain a colorless transparent liquid.

Embodiment 2

[0037] Embodiment 2 Preparation of isomerized tridecyl alcohol polyoxypropylene polyoxyethylene ether

[0038] Add 0.5 mol (100 g) of isomeric tridecanol and 3.19 g of calcium hydroxide catalyst in the pressure reactor, and connect the propylene oxide metering tank to the pressure tank. Replace the air in the kettle with nitrogen for 3 times. After the temperature of the kettle rises to 80-85° C., 1.5 mol (87 g) of propylene oxide is passed through for 2.5 hours, and the reaction is continued for 2.5 hours. After the kettle temperature rose to 140-145°C, 3 mol (132 g) of ethylene oxide was passed through for 2.5 hours, and the reaction was continued for 0.5 hours. After the reaction was completed, it was cooled and the pressure was released to obtain a colorless transparent liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com