Heat treatment method of mg-gd-y-zr series magnesium alloy and its large complex casting

A heat treatment method and magnesium alloy technology, applied in the field of metal structural materials, can solve problems such as cracking of castings, achieve the effects of increasing yield, saving water resources, and improving strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment relates to a large and complex Mg-Gd-Y-Zr series magnesium alloy casting. Under the protection of solvent or gas, the Mg-Gd-Y-Zr series alloy is melted according to the distribution ratio of the components in Table 1 below and then heated up to 750°C, keep it for 1 hour, then lower the temperature to 690-720°C, remove the scum on the surface of the alloy liquid, and then carry out sand casting. The obtained Mg-Gd-Y-Zr series magnesium alloy large complex casting (see figure 1 ) composition (mass percent %) data in Table 1.

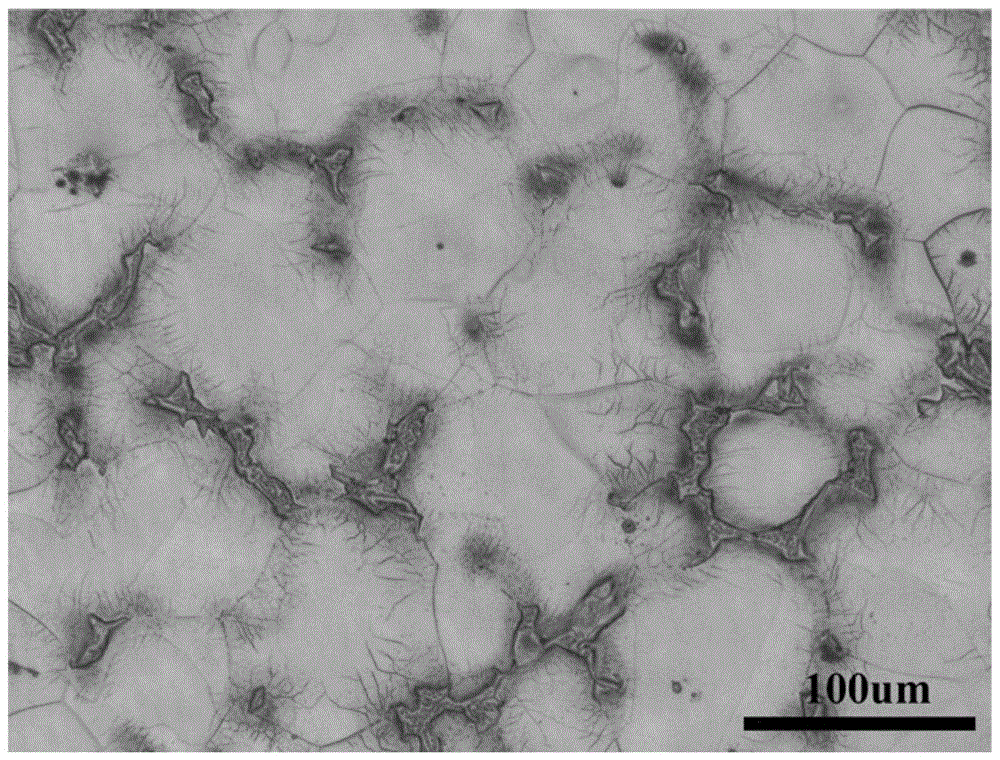

[0041] This embodiment also relates to the heat treatment method for a large and complex casting made of the aforementioned Mg-Gd-Y-Zr series magnesium alloy: take casting 2 and put it into solid solution at 550°C, keep it warm for 8 hours, air cool to room temperature, and then heat Under aging, heat preservation for 8 hours, air cooling to room temperature, no deformation and cracking of castings after heat treatment, see image 3...

Embodiment 2

[0045]This embodiment relates to a large and complex Mg-Gd-Y-Zr series magnesium alloy casting. Under the protection of solvent or gas, the Mg-Gd-Y-Zr series alloy is melted according to the distribution ratio of the components in Table 1 below and then heated up to 750°C, keep it standing for 1 hour, then lower the temperature to 690-720°C, remove the scum on the surface of the alloy liquid, and then carry out sand casting to obtain the complex magnesium alloy casting involved in the invention. The composition data of the obtained casting is shown in Table 1.

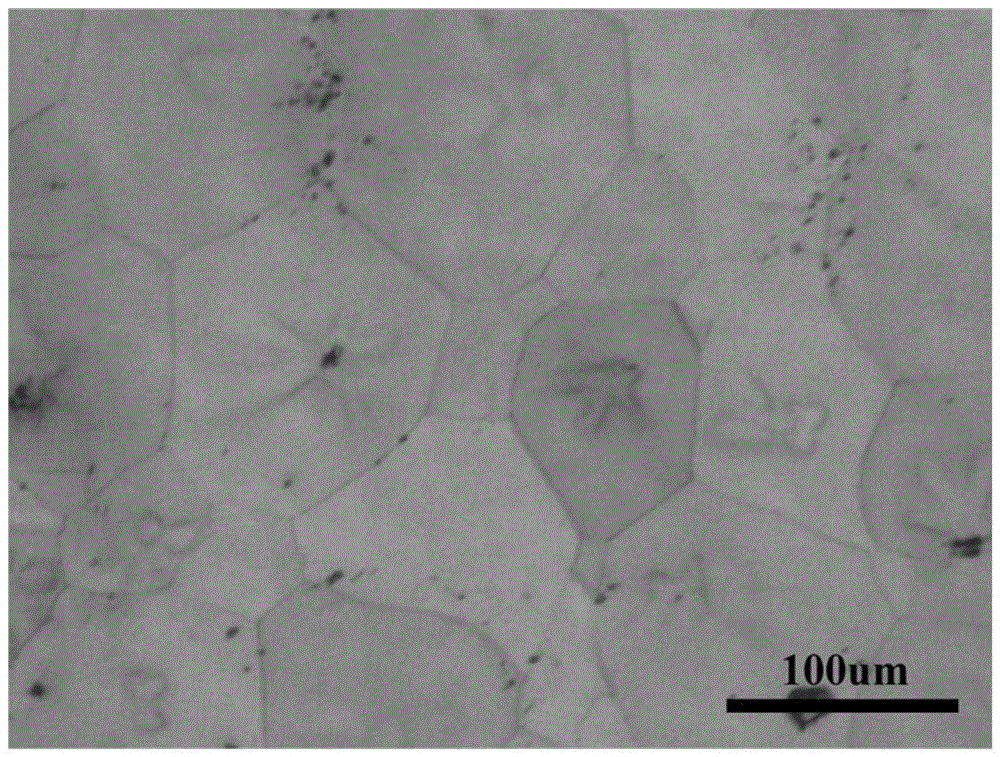

[0046] This example also relates to a heat treatment method for a large and complex casting made of the aforementioned Mg-Gd-Y-Zr series magnesium alloy: take the obtained casting 5 (peak aging state) and put it into solid solution at 525°C, keep it warm for 12 hours, and air cool to At room temperature, aging at 250°C, heat preservation for 10 hours, air cooling to room temperature, no deformation and cracking of casti...

Embodiment 3

[0050] This embodiment relates to a large and complex Mg-Gd-Y-Zr series magnesium alloy casting. Under the protection of solvent or gas, the Mg-Gd-Y-Zr series alloy is melted according to the distribution ratio of the components in Table 1 below and then heated up to 750°C, keep it for 1 hour, then lower the temperature to 690-720°C, remove the scum on the surface of the alloy liquid, and then carry out sand casting. The compositional data of the obtained castings are shown in Table 1.

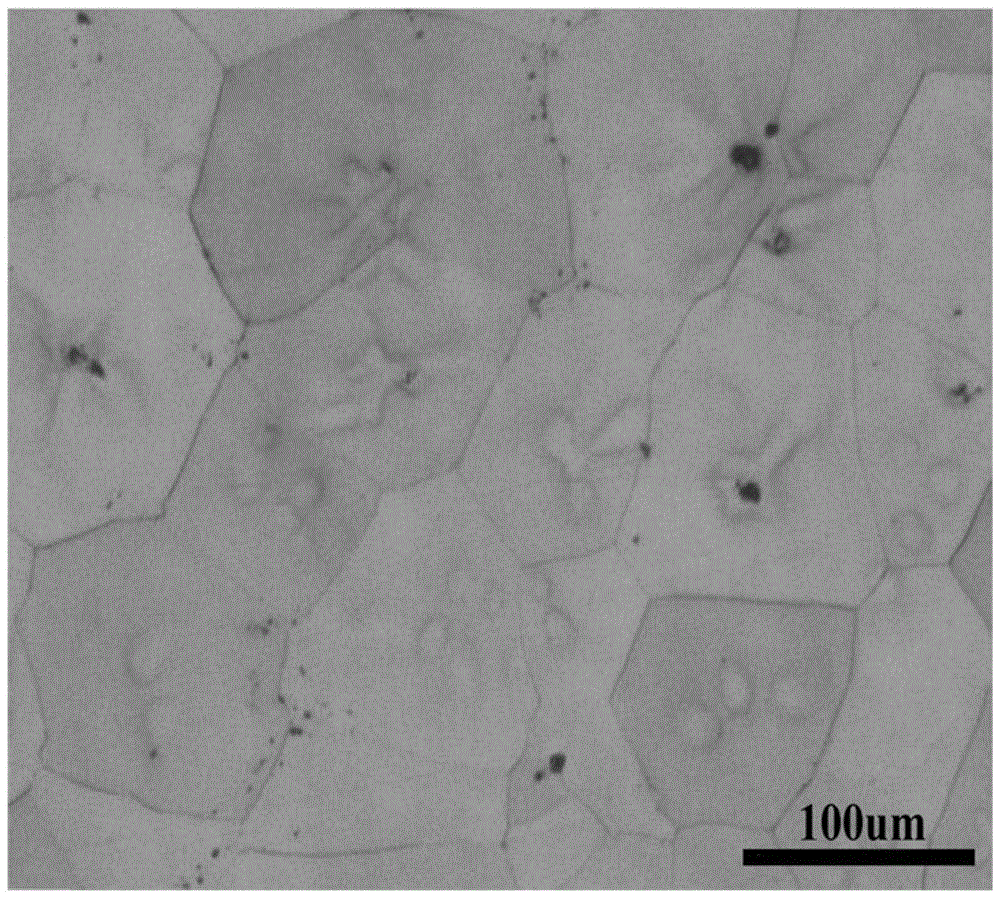

[0051] This embodiment also relates to the heat treatment method for a large and complex casting made of the aforementioned Mg-Gd-Y-Zr series magnesium alloy: take casting 7 and put it into solid solution at 500°C, keep it warm for 16 hours, air cool to room temperature, and then heat Under aging, heat preservation for 20 hours, air cooling to room temperature, no deformation and cracking of castings after heat treatment, see Figure 8 shown.

[0052] Traditional method: take casting 6 and p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com