Process for producing phenol

A technology of phenol and hexylbenzene, applied in the field of preparing phenol, can solve the problems such as reducing the yield of cyclohexanone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

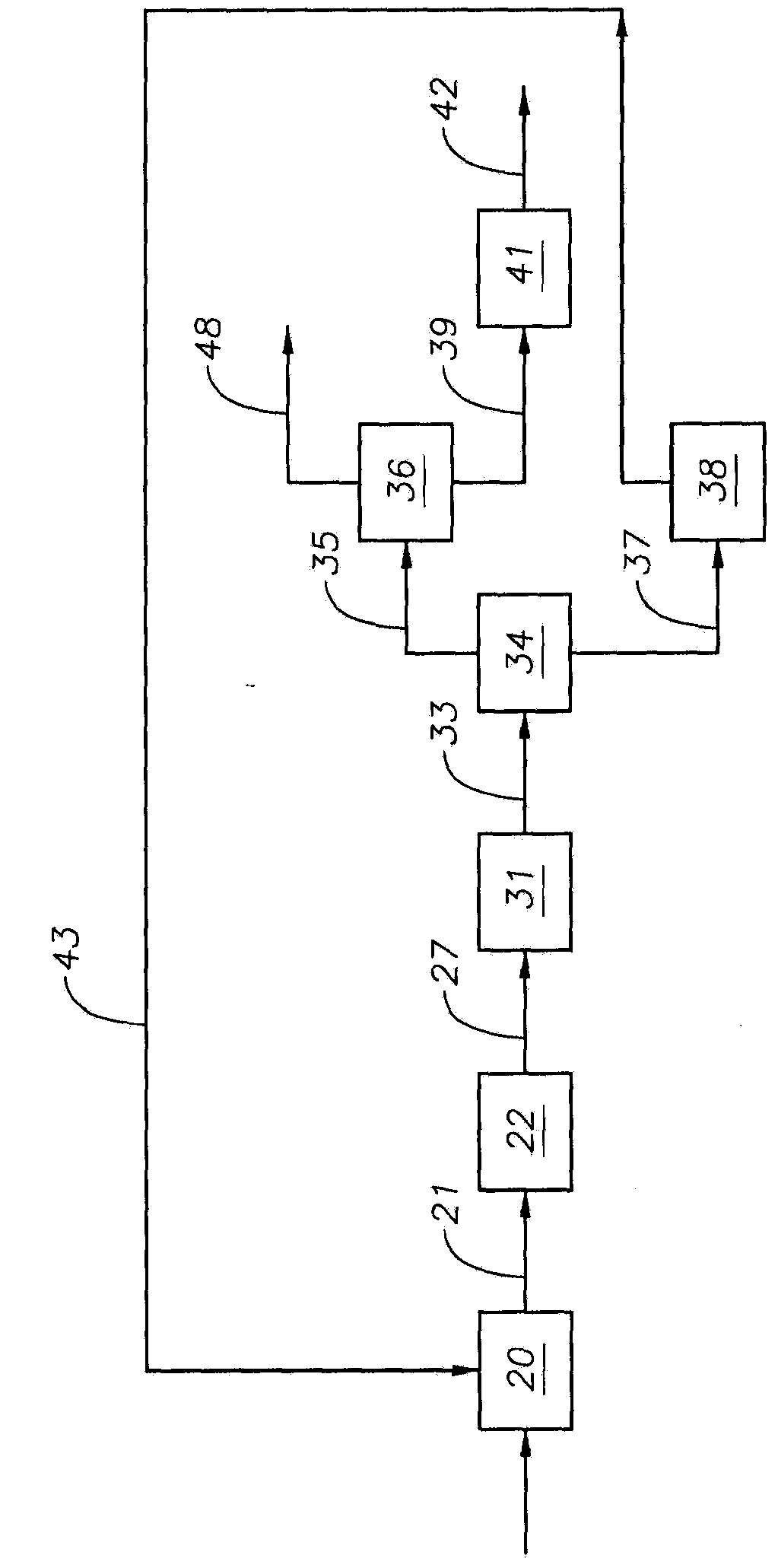

[0028] Described herein is a process for preparing phenol by oxidizing cyclohexylbenzene to form a first reaction product comprising cyclohexylbenzene hydroperoxide and then cleaving at least a portion of the cyclohexylbenzene hydroperoxide to form a reaction product comprising phenol and cyclohexylbenzene. The second reaction product of hexanone. One or both of the first and second reaction products contain cyclohexenone as an impurity, which is difficult to separate from the desired cyclohexanone by conventional distillation. Accordingly, the process of the present invention employs selective hydrogenation to convert at least a portion of the cyclohexenone in the first and / or second reaction product to cyclohexanone. The selective hydrogenation process is accompanied by only minimal yield losses of the desired cyclohexanone.

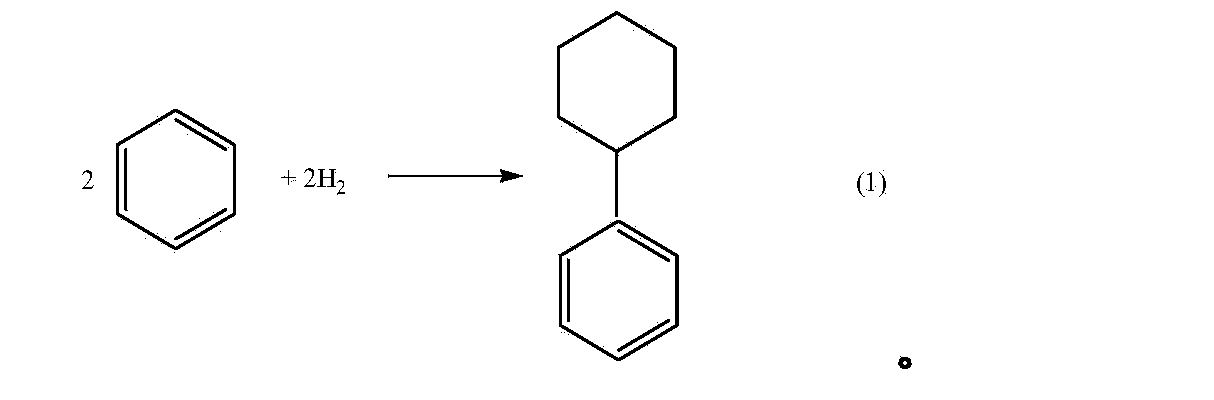

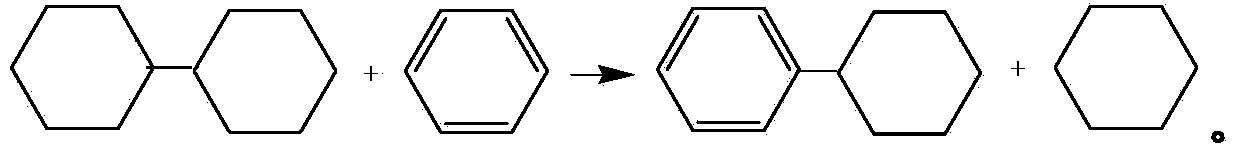

[0029] Preparation of cyclohexylbenzene

[0030] Any known technique may be used to prepare the cyclohexylbenzene (CHB) employed in the process of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com