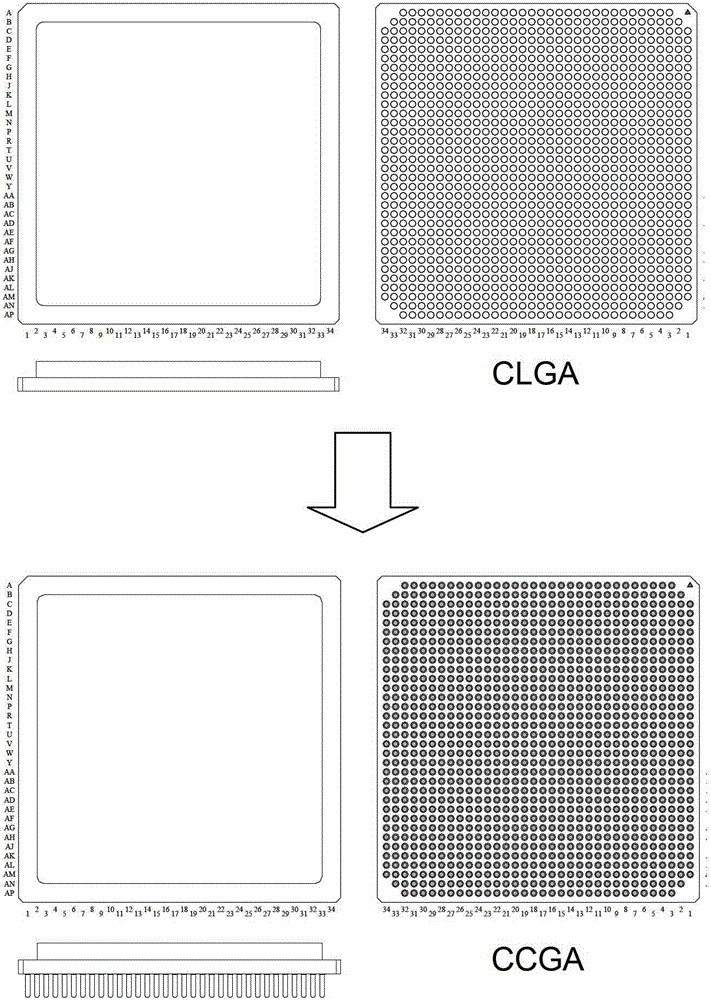

Arrangement device for CCGA (ceramic column grid array) packaging welding columns and pins

A technology for arranging devices and welding pins, which is applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of being unsuitable for multi-variety, multi-batch production, low production efficiency, long production cycle, etc., and achieves simple structure, location Good precision, suitable for mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

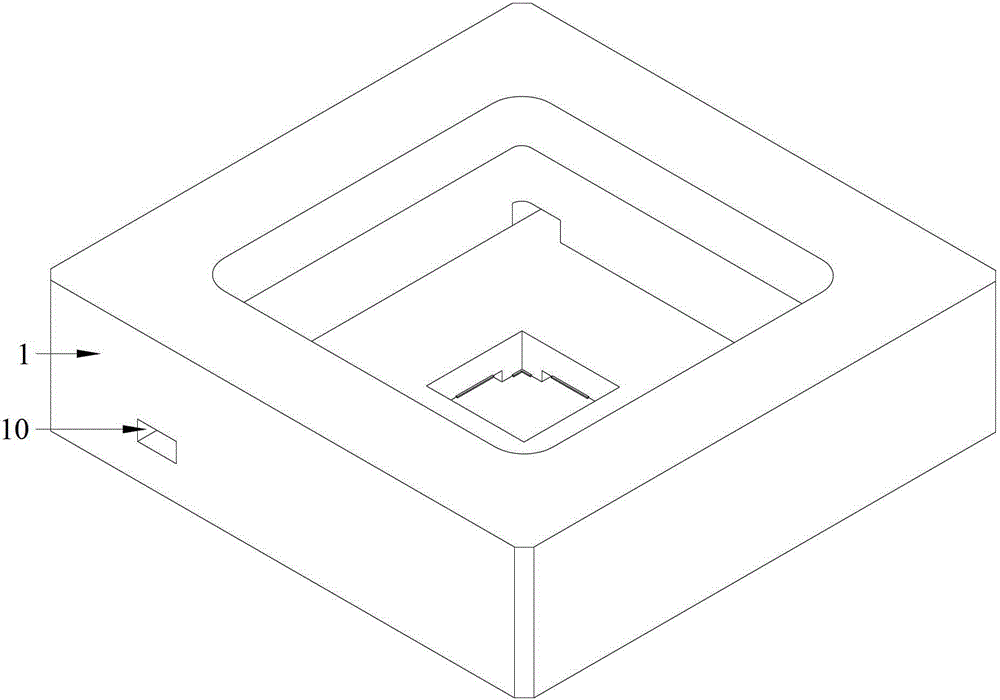

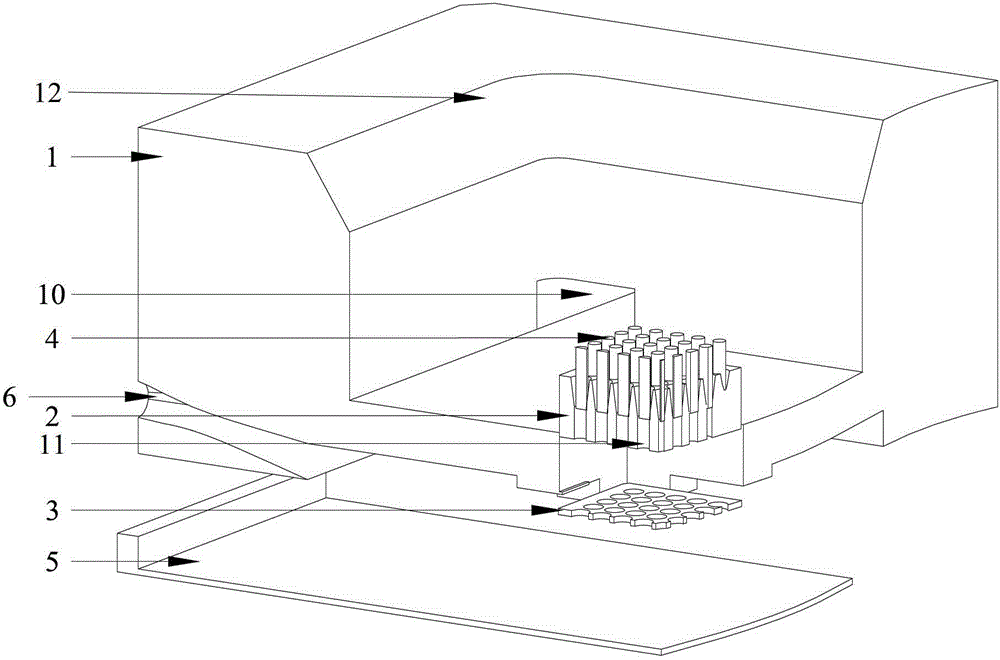

[0023] Example 1: 1.27mm pitch CCGA560 and CCGA575 welding columns are arranged as follows Figure 5 shown.

[0024] The 1.27mm pitch CCGA560 and CCGA575 welding post arrangement devices have a pitch of 1.27mm, Φ0.60mm, and the number of arrays is 50×50.

[0025] See Figure 5 a, the package soldering post arrangement after arrangement and soldering see Figure 5 b;

[0026] When the 1.27mm pitch CCGA575 welding columns are arranged, replace the stopper (24×24 array), see Figure 5 c. See Figure 5 d.

Embodiment 2

[0027] Example 2: 1.00mm pitch CCGA1144 and CCGA1760 welding columns are arranged as Image 6 shown.

[0028] The 1.00mm pitch CCGA1144 and CCGA1760 welding post arrangement devices have preset positioning block 2 through-hole pitches of 1.00mm and Φ0.50mm, and the number of arrays is 50×50.

[0029] 1.00mm pitch CCGA1144 welding column arrangement block see Image 6 a, 34×34 array, after arrangement and soldering see Image 6 b;

[0030] When the 1.00mm pitch CCGA1760 welding columns are arranged, replace the block, see Image 6 c, 42×42 array, after arrangement and soldering see Image 6 d.

[0031] It can be seen that the welding column / welding needle arrangement device provided by the present invention has the following characteristics:

[0032] (1) The present invention utilizes vacuum suction traction, wide-mouth guide and 12-hole guide, and the welding column falls under gravity when tilted, and the welding column / welding needle arrangement and alignment are compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com