Preparation method of graphene nanoplatelet/epoxy resin nanocomposite material

A nano-composite material and graphene micro-sheet technology are applied in the field of preparation of graphene micro-sheet/epoxy resin nano-composite materials, which can solve problems such as the limitation of re-dispersion, reduce melting dripping, improve limiting oxygen index, Improve the effect of combustion to charcoal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

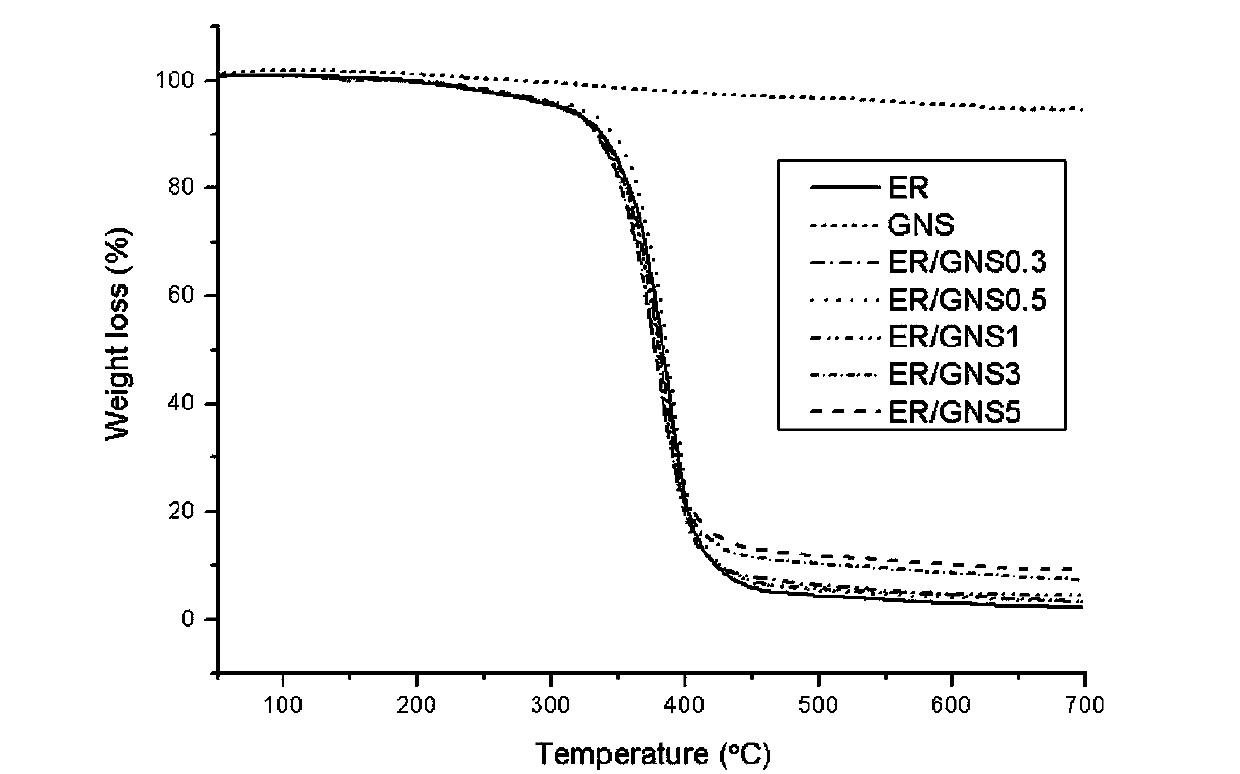

[0028] For the graphene microflake / epoxy resin nanocomposite material prepared in this example, the weight ratio of epoxy resin, curing agent, and graphene microflake is 100:33:5.

[0029] The preparation method is as follows:

[0030] 5 g of graphene microflakes were dispersed in acetone to form a suspension, so that the concentration of the suspension was 10 mg / ml. The suspension was put into a sonicator, and an ice-water mixture was put into the sonicator at the same time, and stirred in an ice bath with a power of 250W for 1.5 hours while sonicating. Add 100 g of epoxy resin monomer JY-256 to the resulting solution, and continue to stir for 1.5 hours while ultrasonically stirring in an ice bath with a power of 250 W. The resulting mixture was placed in a 60°C oil bath and stirred for 5 hours. Then put it into a vacuum oven, and vacuumize at 60° C. for 2 hours. The resulting mixture was cooled to room temperature, 33 g of curing agent D230 was added, and stirred for 0.5 ...

Embodiment 2

[0033] For the graphene microflake / epoxy resin nanocomposite material prepared in this example, the weight ratio of epoxy resin, curing agent, and graphene microflake is 100:33:3.

[0034] The preparation method is as follows:

[0035] 3 g of graphene microflakes were dispersed in acetone to form a suspension, so that the concentration of the suspension was 10 mg / ml. The suspension was put into a sonicator, and an ice-water mixture was put into the sonicator at the same time, and stirred in an ice bath with a power of 250W for 1.5 hours while sonicating. Add 100 g of epoxy resin monomer JY-256 to the resulting solution, and continue to stir for 1.5 hours while ultrasonically stirring in an ice bath with a power of 250 W. The resulting mixture was placed in a 60°C oil bath and stirred for 5 hours. Then put it into a vacuum oven, and vacuumize at 60° C. for 2 hours. The resulting mixture was cooled to room temperature, 33 g of curing agent D230 was added, and stirred for 0.5 ...

Embodiment 3

[0038] For the graphene microflake / epoxy resin nanocomposite material prepared in this example, the weight ratio of epoxy resin, curing agent, and graphene microflake is 100:33:1.

[0039] The preparation method is as follows:

[0040]Take 1 g of graphene microflakes and disperse them in acetone, so that the concentration of the suspension is 10 mg / ml. The suspension was put into a sonicator, and an ice-water mixture was put into the sonicator at the same time, and stirred in an ice bath with a power of 250W for 1.5 hours while sonicating. Add 100 g of epoxy resin monomer JY-256 to the resulting solution, and continue to stir for 1.5 hours while ultrasonically stirring in an ice bath with a power of 250 W. The resulting mixture was placed in a 60°C oil bath and stirred for 5 hours. Then put it into a vacuum oven, and vacuumize at 60° C. for 2 hours. The resulting mixture was cooled to room temperature, 33 g of curing agent D230 was added, and stirred for 0.5 hours. The res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com