Method of producing gasoline for car from synthetic naphtha

A naphtha, production vehicle technology, applied in the petroleum industry, hydrocarbon oil treatment, hydrotreating process and other directions, can solve the problem of low octane number of synthetic naphtha, improve the overall economic benefits, and improve the octane number , the effect of low sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

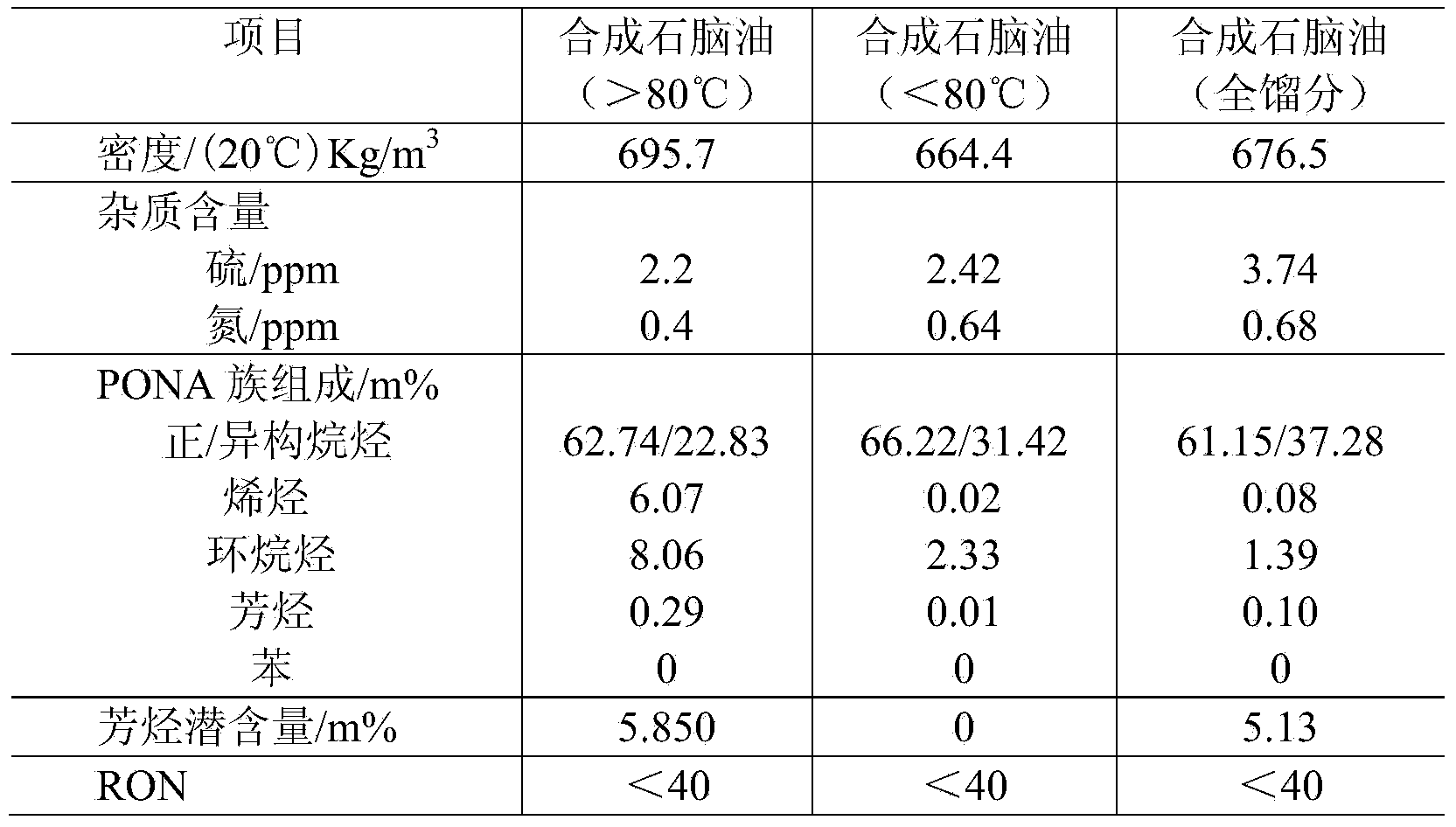

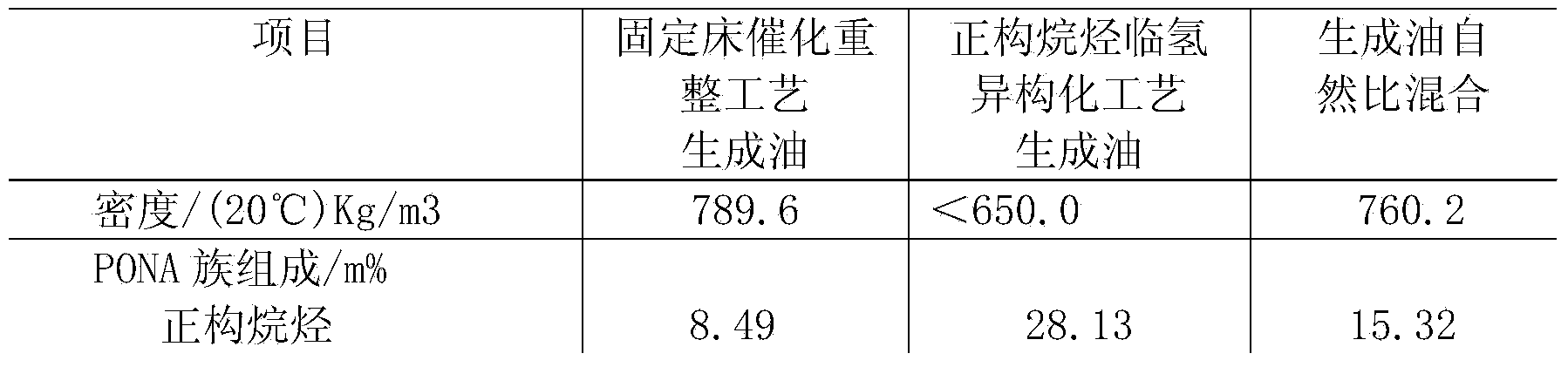

[0011] The main physicochemical properties of the naphtha synthesized by the coal indirect liquefaction process adopted in this embodiment are as follows:

[0012]

[0013] The concrete steps of the inventive method are as follows

[0014] ①Raw material pretreatment process:

[0015] The naphtha synthesized by the coal indirect liquefaction process is sent to the fractionation tower, and the components ≤ C4 are removed from the top of the tower, and the C5-C6 fraction is fractionated in the first line of the tower as the feed for the normal paraffin hydroisomerization process, and the bottom of the tower is obtained The ≥80°C distillate is used as the feed for the fixed bed reforming process.

[0016] ② Hydroisomerization process of n-paraffins:

[0017] The C5-C6 distillate from the first line of the tower is mixed with hydrogen and heated to a reaction temperature of 250-270°C, then enters a fixed-bed isomerization reactor and undergoes isomerization reaction under the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com