Blended fabric for thermoplastic fiber reinforced composite materials and preparing method of blended fabric

A technology for reinforcing composite materials and thermoplastic fibers, which can be used in fabrics, textiles, textiles and papermaking, etc., can solve the problems of uneven prepreg and complex production process, and achieve the effect of improving product quality and shortening product molding cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

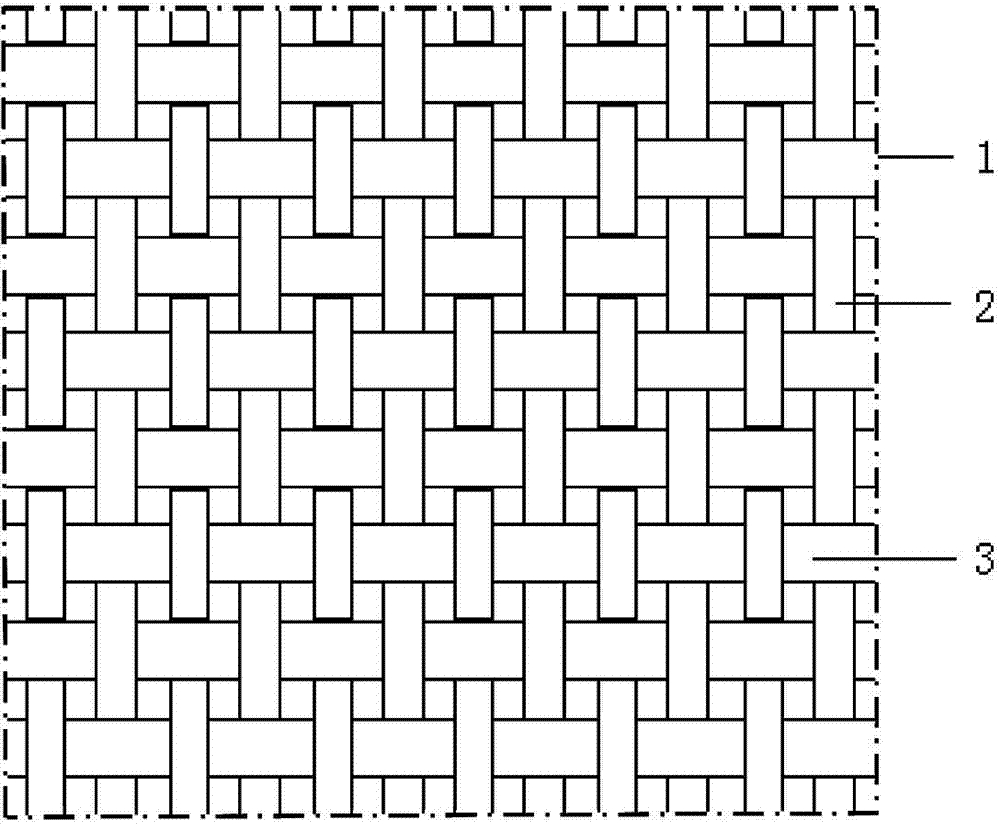

[0011] According to attached figure 1 , the product of the present invention is formed by interweaving a group of parallel warp yarns 2 and a group of parallel weft yarns 3 according to a certain structure and density according to product requirements. The quality of warp yarn 2 and weft yarn 3 can be completely the same or different, but they respectively contain two components of reinforcing fiber and thermoplastic matrix fiber. During compression molding, the thermoplastic matrix fibers are heated and melted, and under pressure, the reinforcing fibers are impregnated and bonded.

Embodiment 2

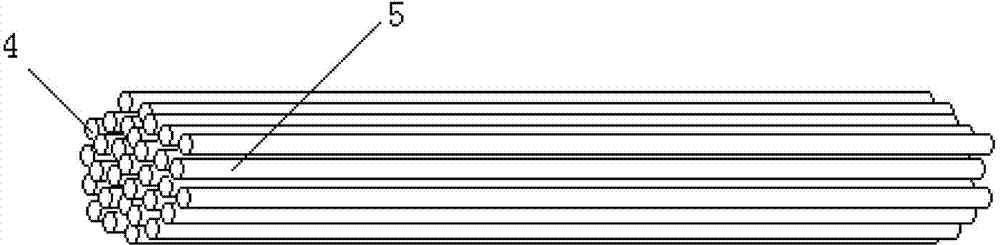

[0013] According to attached figure 2 , the thermoplastic matrix fiber and the reinforcing fiber used in the present invention are both in the form of filaments, and the reinforcing fiber filament 4 and the thermoplastic matrix fiber filament 5 are merged into a continuous filament yarn through a doubling process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com