Automatic generation method of secondary electrical schematic diagrams based on Auto CAD

An electrical schematic diagram and automatic generation technology, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of shortened delivery time, high error rate, low efficiency, etc., and achieve shortened production cycle and design efficiency. And the effect of improving accuracy and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

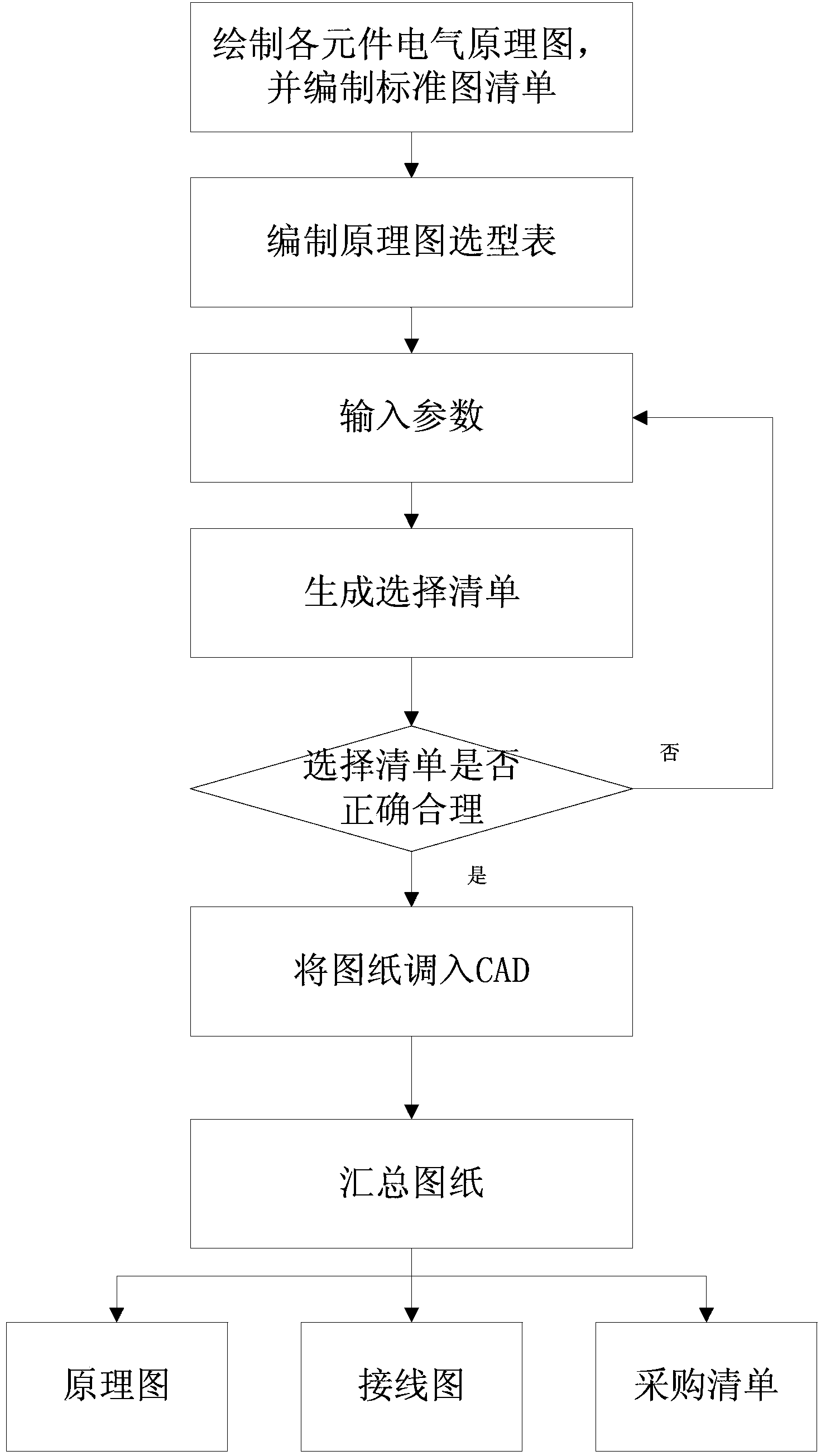

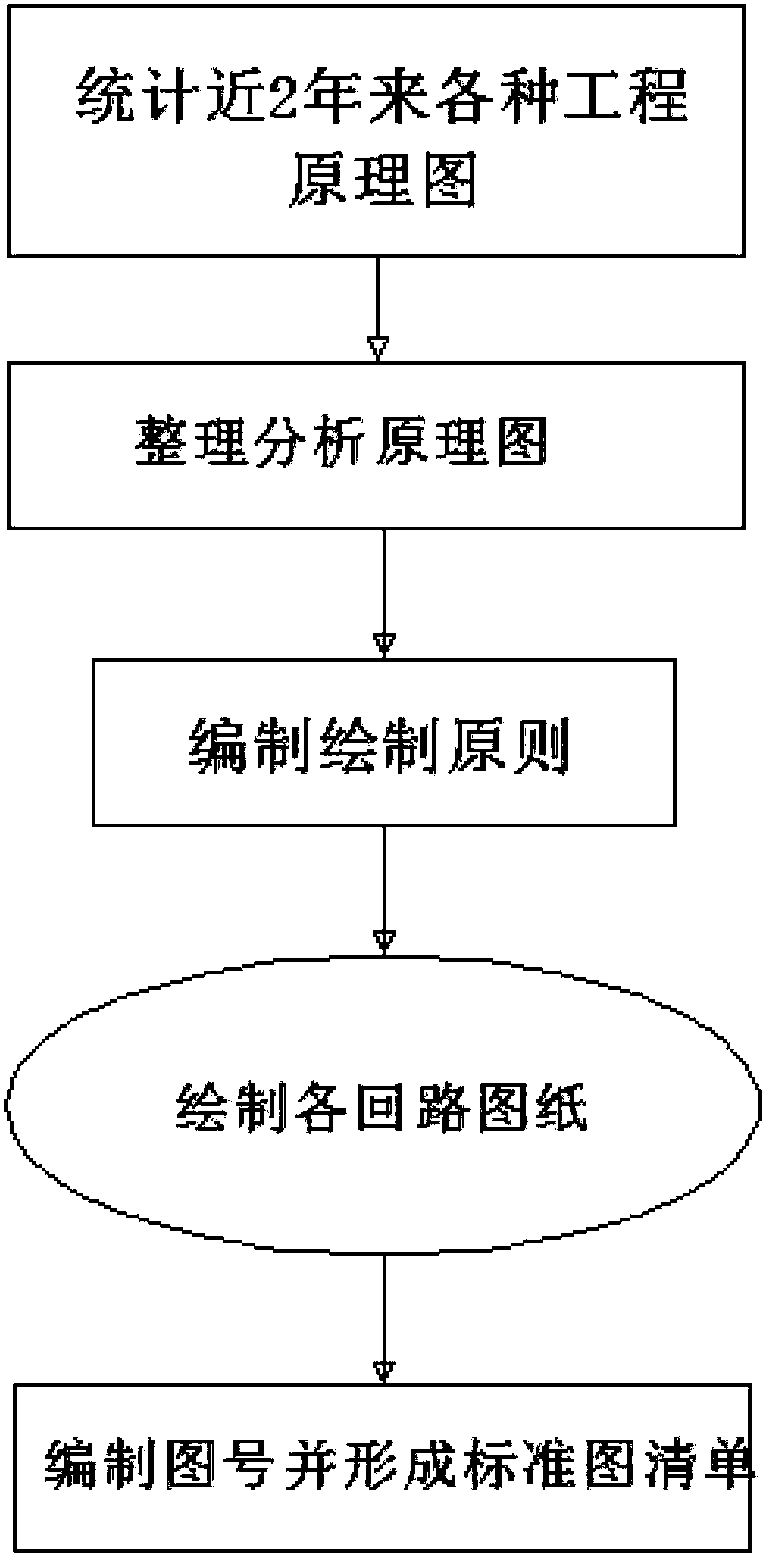

[0042] The flow chart of the automatic generation method of the secondary electrical schematic diagram based on Auto CAD is as follows: figure 1 and figure 2 shown.

[0043] This method is based on electrical secondary principle design technology and computer technology, using EXCEL VBA technology and Aout CAD software, specifically including the following steps:

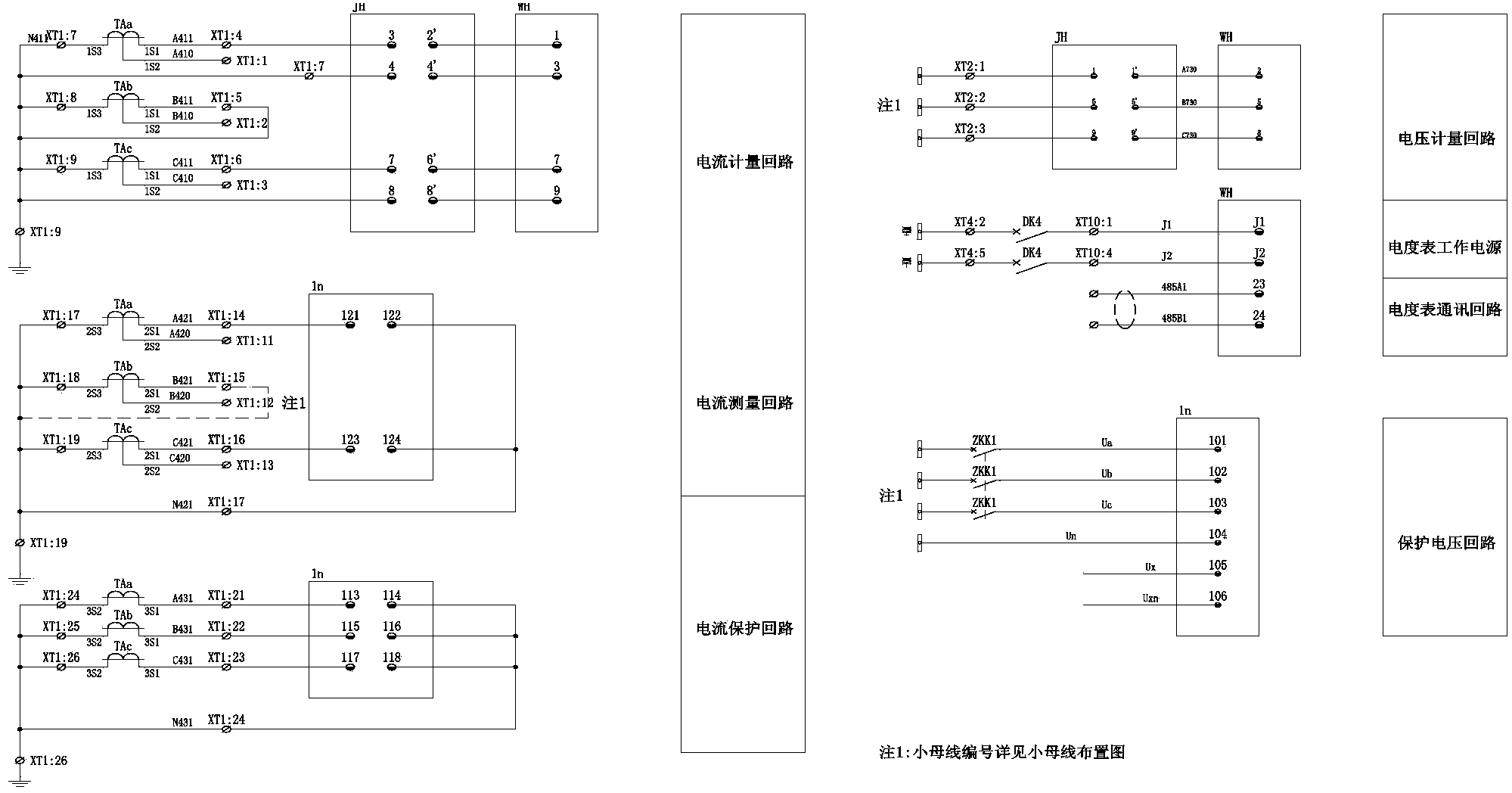

[0044] Step (1): Modularize the factory-made secondary electrical schematic diagrams of various components of the complete set of switchgear, and compile a list of standard diagrams. Combined with the specific use of the enterprise, the use of various engineering schematic diagrams in the past two years has been counted. After sorting out and analyzing, a unified drawing principle and the number of fixed common components have been formulated, as shown in Table 1:

[0045] Table 1 Drawing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com