Inductor and formation method thereof, and integrated passive device and formation method thereof

A technology for integrating passive devices and inductors, which is applied in the semiconductor field, can solve problems such as high requirements and complex structure and process of Litz wire inductors, and achieve the effects of improving quality factor, reducing loss, and increasing cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

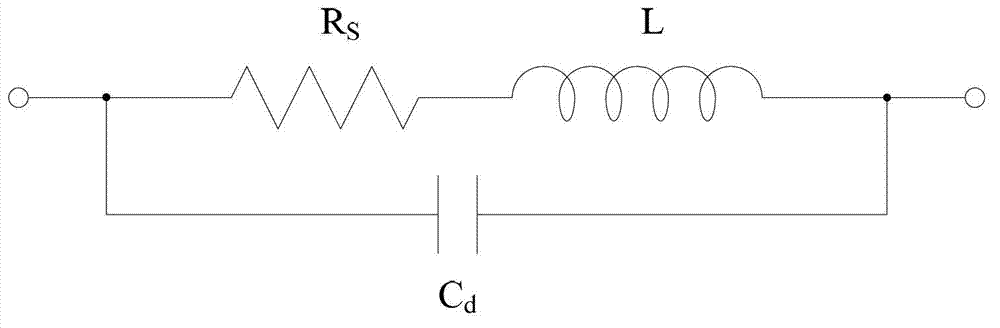

[0039] As mentioned in the background section, the quality factor of the existing planar inductor structure is low. Although the quality factor of the litz wire inductor structure is high, the layout requirements for each wire in the litz wire inductor structure are high, and the process of forming the litz wire inductor structure is complicated.

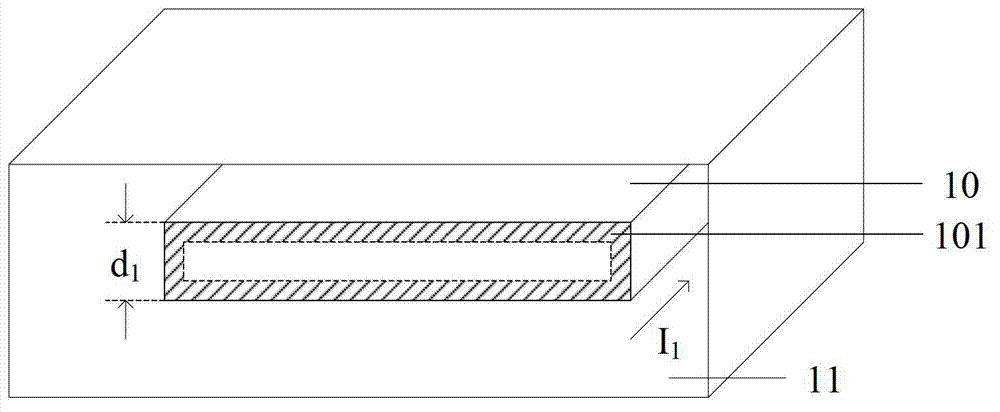

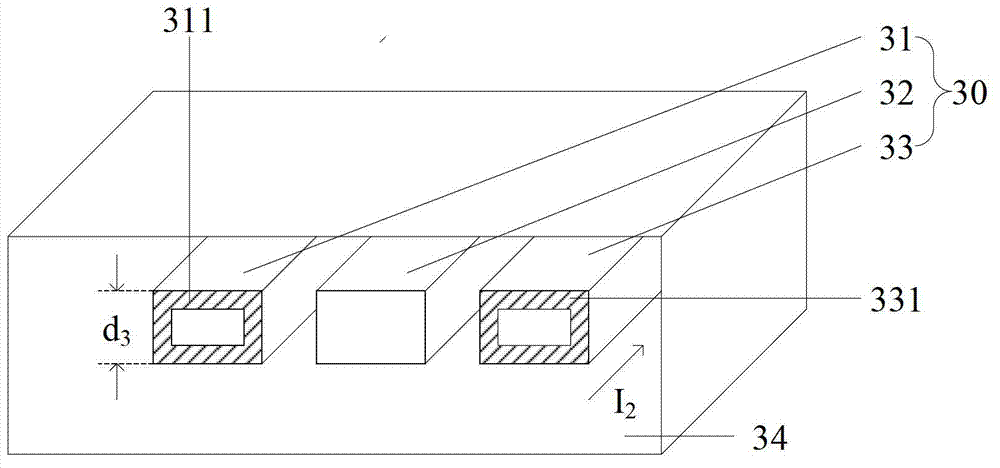

[0040]After research, it is found that the metal layer under the first opening can be removed by forming a mask layer including the first opening and the second opening on the flat metal layer, and etching the metal layer along the first opening and the second opening. layer, and a metal layer with a predetermined thickness remains under the second opening to form an inductor. The formed inductor includes a body and a plurality of spaced apart flanges located on the upper surface of the body. The surface area of the inductor including the body and the flange is larger compared to the flat metal layer. Since one end of each flange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com