High energy density lithium ion battery

A lithium-ion battery, high energy density technology, applied in secondary batteries, secondary battery repair/maintenance, circuits, etc., can solve the problems of SEI film instability, performance degradation, particle rupture, etc., to improve the first-time efficiency and energy Density, the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

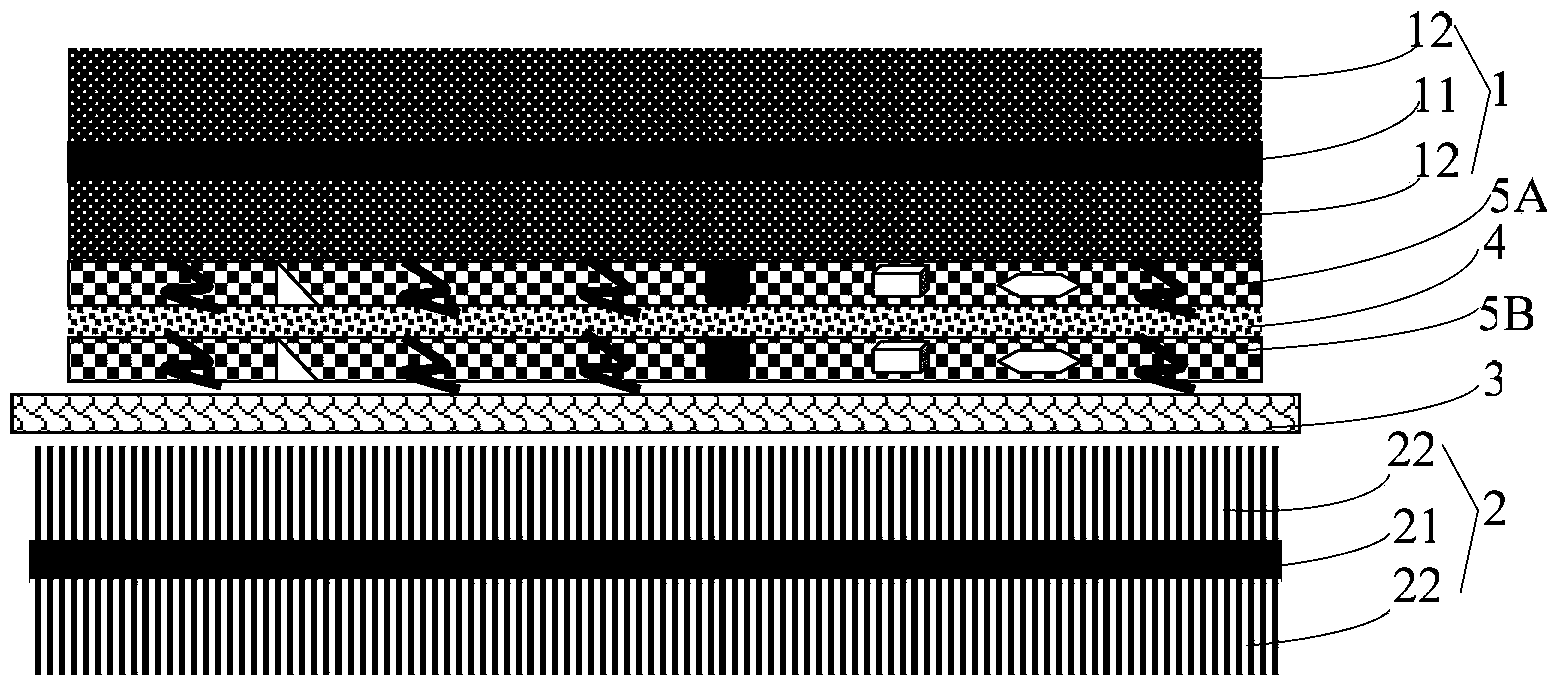

[0051] Embodiment 1 (with reference to figure 1 )

[0052] Preparation of positive electrode sheet 1 for lithium-ion batteries: LiCoO 2 As the first positive electrode active material, LiNi 0.5 mn 0.3 co 0.2 o 2 As the second positive electrode active material (wherein the mass ratio of the first positive electrode active material to the second positive electrode active material is 80:20), PVDF is used as a binder, and conductive carbon (SP) is used as a conductive agent according to the positive electrode active material: PVDF: SP mass The ratio is 96:2:2, dissolved in the solvent N-methylpyrrolidone (NMP) and stirred evenly to make a slurry, and then the slurry is evenly coated on the positive electrode current collector 21 (using aluminum foil), and dried to make lithium The positive electrode sheet 1 of the ion battery.

[0053] Preparation of the first polymer conductive layer 5A: using carbon nanotubes (CNTs) as electronically conductive materials, Al 2 o 3 As an...

Embodiment 2

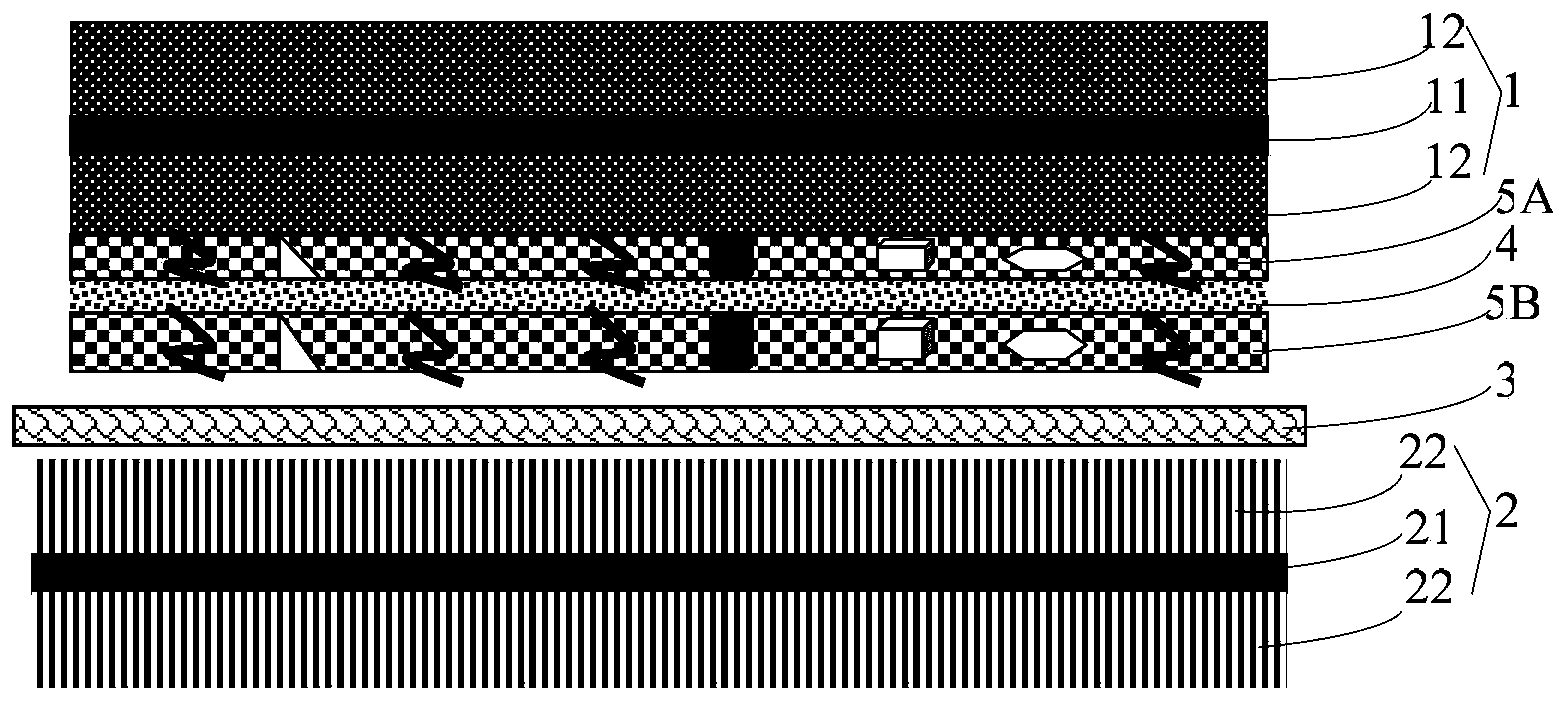

[0059] Embodiment 2 (with reference to figure 2 )

[0060] Preparation of positive electrode sheet 1 for lithium-ion batteries: LiCo 0.8 al 0.2 o 2 As the first positive electrode active material, Li 1.3 mn 2 o 4 As the second positive electrode active material (wherein the mass ratio of the first positive electrode active material to the second positive electrode active material is 95:5), PVDF is used as a binder, and conductive carbon (SP) is used as a conductive agent, according to the positive electrode active material: PVDF: The mass ratio of SP is 96:2:2, which is dissolved in N-methylpyrrolidone (NMP) and stirred evenly to make a slurry, and then the slurry is evenly coated on the positive electrode current collector 21 (using aluminum foil), and then dried Lithium-ion battery positive pole piece 1.

[0061] Preparation of the first polymer conductive layer 5A: using conductive carbon (SP) as the electronically conductive material, SiO 2As an ion-conducting mat...

Embodiment 3

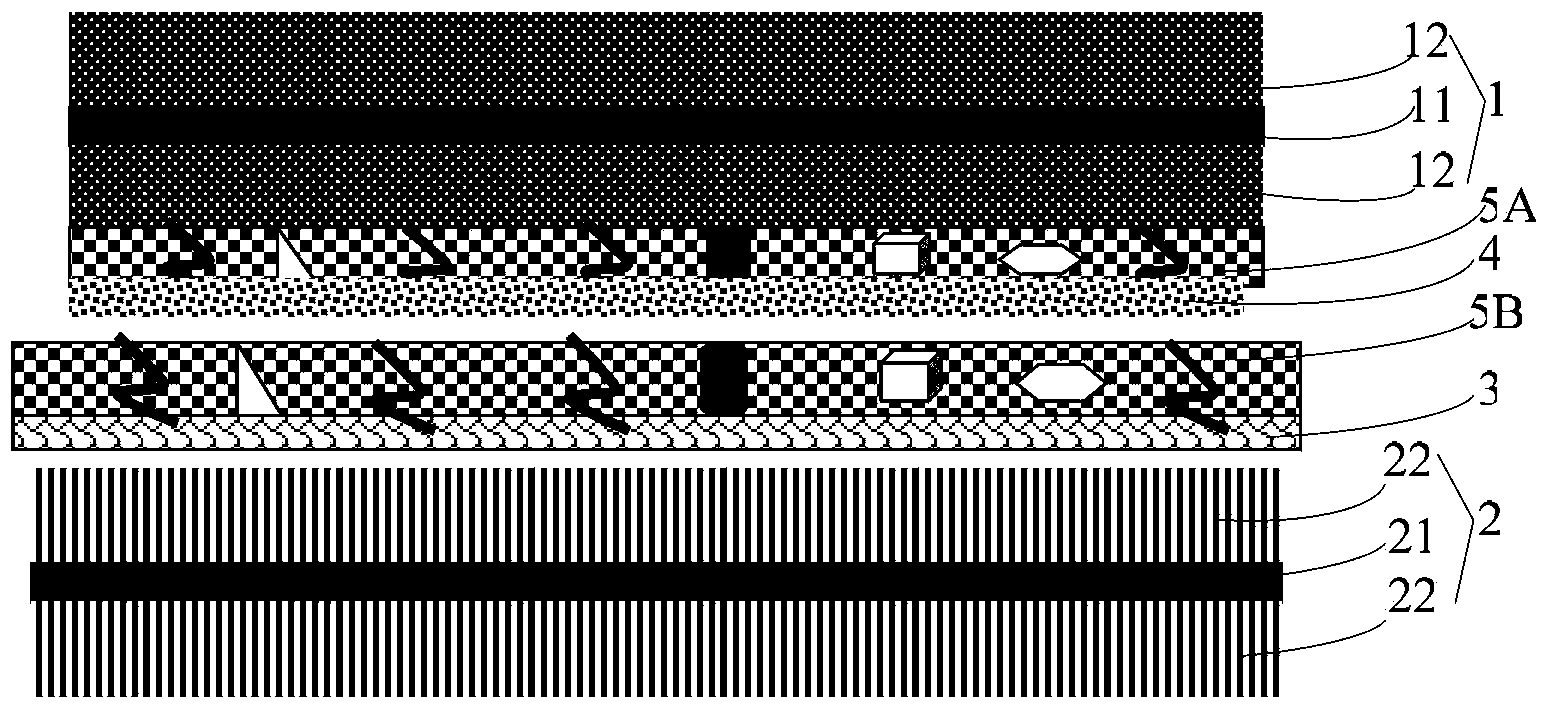

[0067] Embodiment 3 (with reference to image 3 )

[0068] Preparation of positive electrode sheet 1 for lithium-ion batteries: LiCoO 2 As the first positive electrode active material, LiNi 0.8 co 0.15 al 0.05 o 2 As the second positive electrode active material (wherein the mass ratio of the first positive electrode active material to the second positive electrode active material is 60:40), PVDF is used as a binder, and conductive carbon (SP) is used as a conductive agent according to the positive electrode active material: PVDF: SP mass The ratio is 96:2:2, dissolved in the solvent N-methylpyrrolidone (NMP) and stirred evenly to make a slurry, and then the slurry is evenly coated on the positive electrode current collector 21 (using aluminum foil), and dried to make lithium Positive pole piece 1 of ion battery.

[0069] Preparation of the first polymer conductive layer 5A: using CNT as an electronically conductive material, Li 3 PO 4 As an ion-conducting material, SB...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com