Soilless culture trough and application thereof

A technology of soilless cultivation and cultivation substrate, applied in the field of plant cultivation, can solve the problems of high one-time investment and operation cost, incomplete disinfection effect, labor-intensive and labor-intensive, etc., and achieve the effects of increased yield, enhanced absorption capacity, and increased yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the drawings.

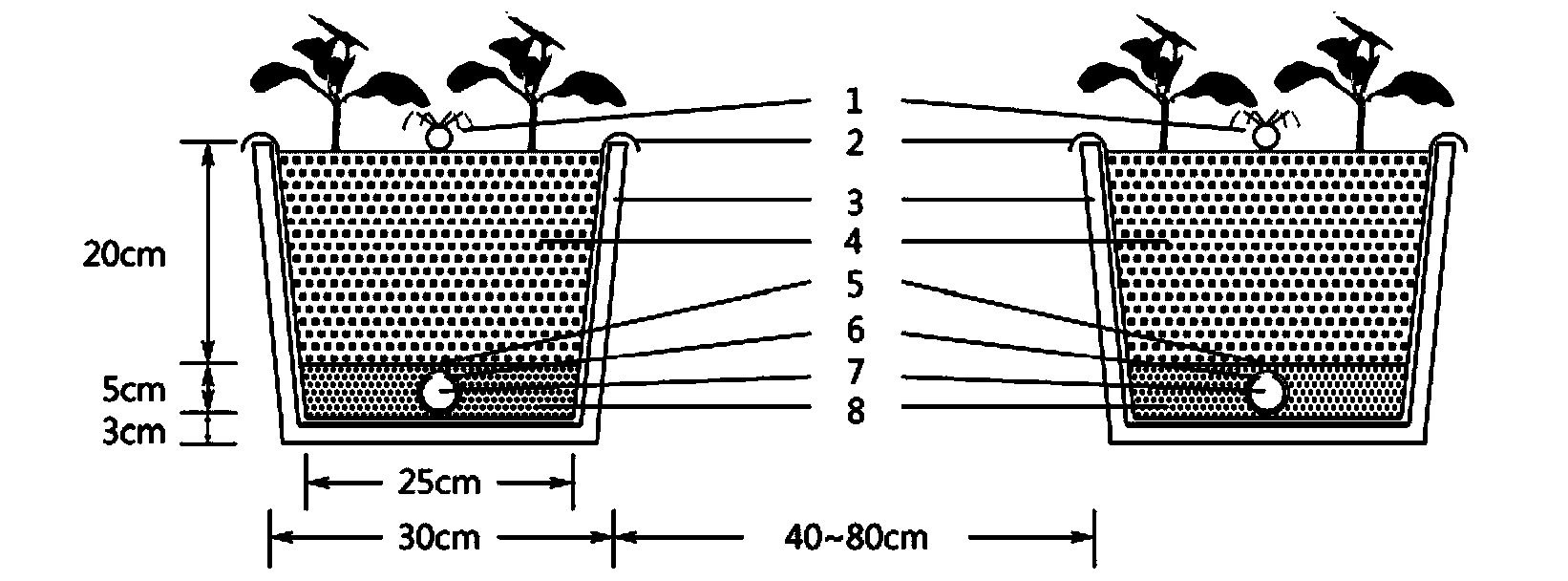

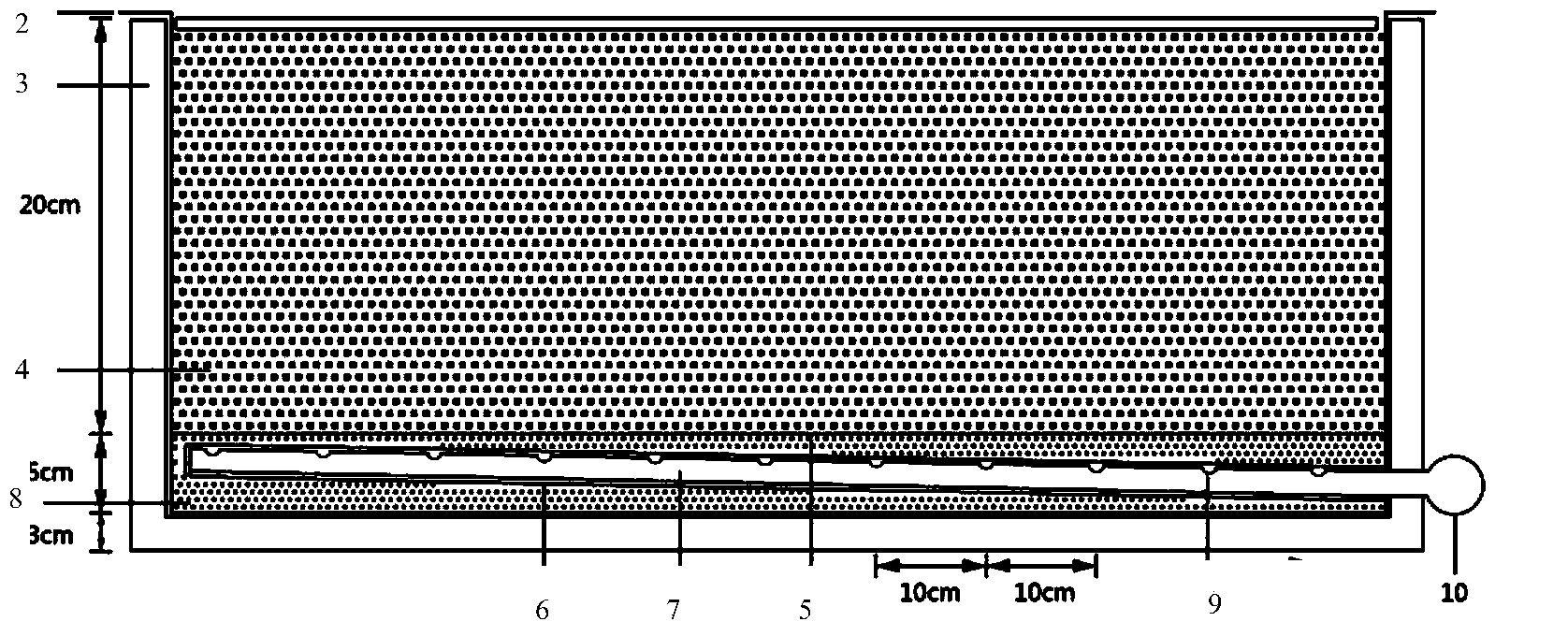

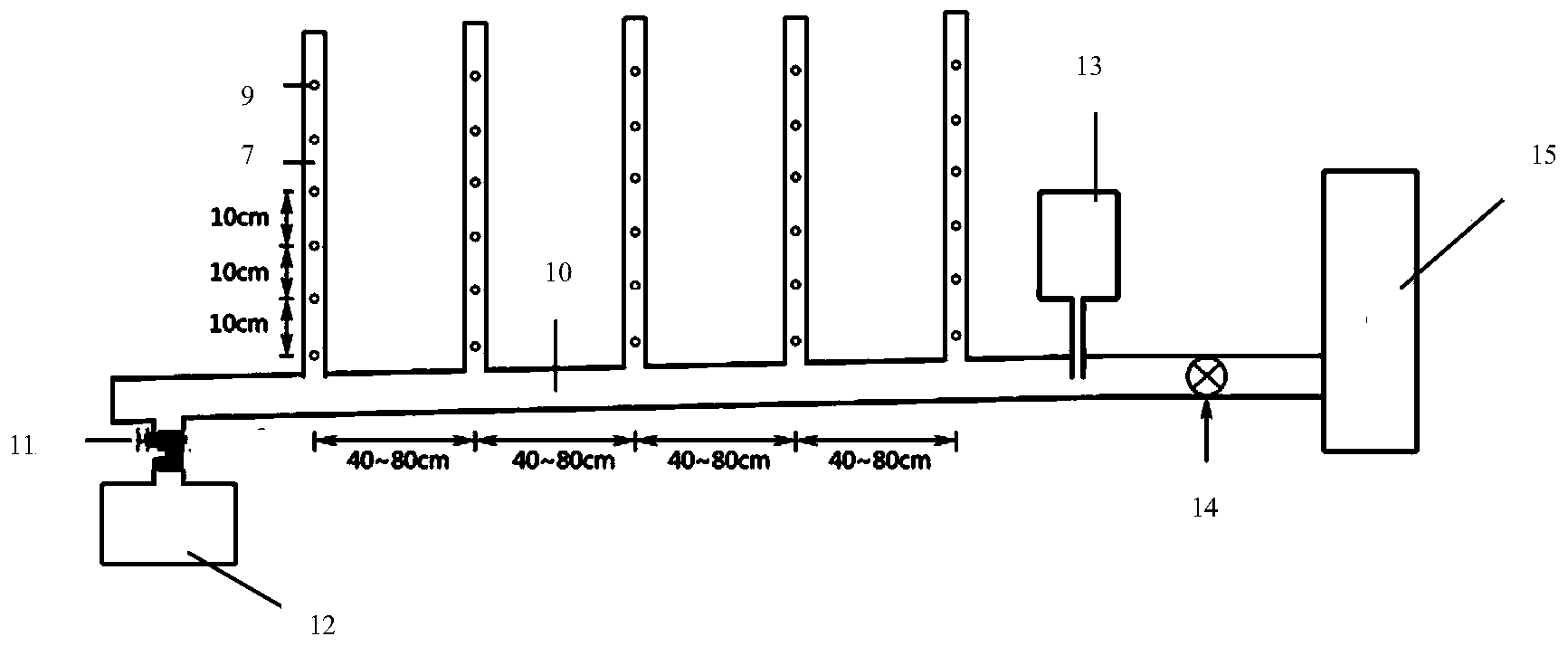

[0028] As shown in the figure, the soilless culture system includes a foam plastic tank 3, a vent pipe 7, a liquid collection tank or a liquid supply tank 12, a hot blast stove 15, an axial fan 14 and an ozone generator 13 and so on. The upper inner diameter of the foamed plastic tank 3 is 30cm wide, the lower inner diameter is 25cm wide, the inner diameter is 25cm high, the foam tank is 3cm thick, and the single length is 1m. It can be extended according to the greenhouse structure. After the length of the cultivation tank is determined, use a 0.1mm thick plastic film 2 Lining the periphery of the foam plastic tank 3, the spacing between each cultivation tank is 40-80cm. The 0.1mm thick plastic film 2 lining the periphery of the foam tank can play a role in retaining fertilizer and water, preventing the water and fertilizer sprayed from the drip irrigation belt 1 from losin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com