Preparation method of ultrafine tungsten carbide powder

A technology of ultra-fine tungsten powder and tungsten carbide powder, which is applied in the direction of carbide, tungsten/molybdenum carbide, etc., can solve the problems of high production cost, complicated equipment, unfavorable batch production, etc., and achieve improved effect, uniform particle size distribution, The effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

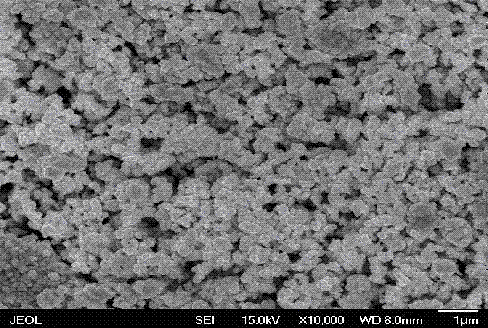

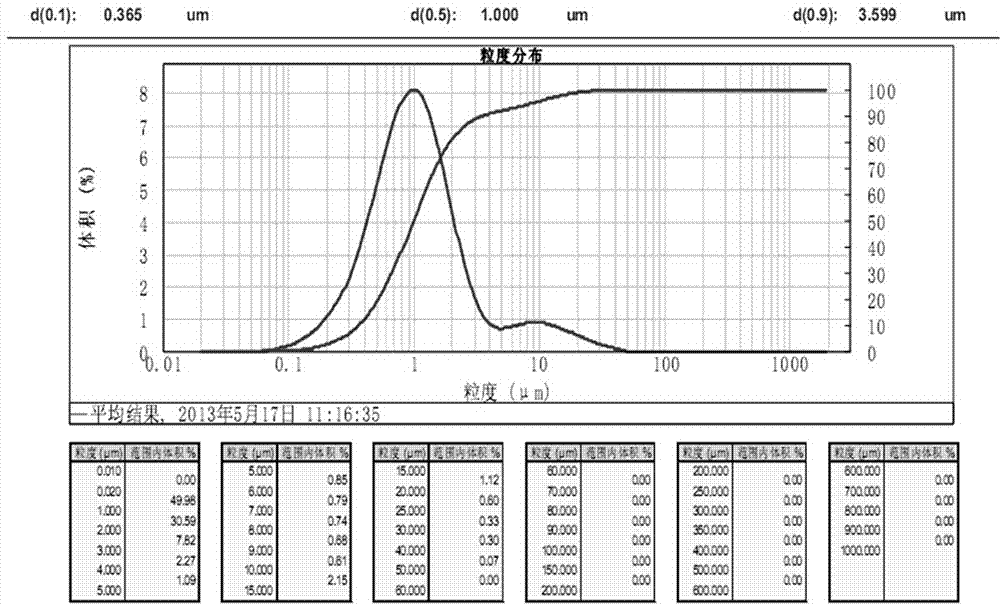

[0025] Embodiment 1: superfine tungsten carbide powder according to the following steps:

[0026] (1) According to the following mass percentage, the ultrafine tungsten powder is 88.90% (BET particle size is 0.05μm), carbon black is 6.10%, and ultrafine tungsten carbide is 5% (BET particle size is 0.15μm). Oxygen content in the powder, the mass percentage of carbon black is 0.3% higher than the mass percentage of carbon calculated according to the WC stoichiometric ratio [that is, the value of 6.10%-88.90%×(12 / 183.85) is 0.3%], the above proportion of powder Put the materials into a ball mill, add stainless steel balls, and then ball mill and mix for 8 hours to mix the materials evenly.

[0027] (2) Unload the mixed material from the ball mill, and separate the ball material, then put the material into a graphite boat, and carbonize in a carbonization furnace. The carbonization atmosphere is a non-oxidizing atmosphere, and the carbonization temperature is 1000°C. , the carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com