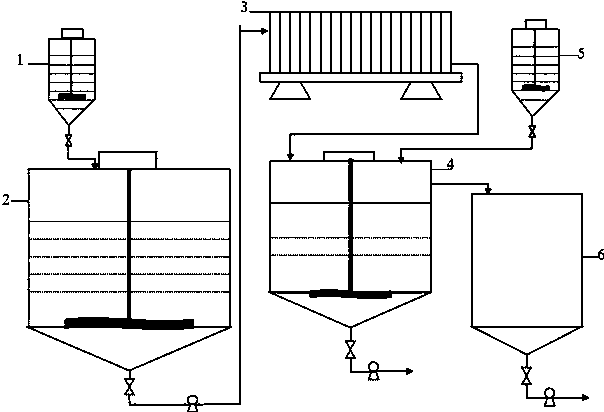

Process and equipment for recycling filter pressing waste water in production of nano activated calcium carbonate

A technology of activated calcium carbonate and filter press wastewater, which is applied in the direction of calcium carbonate/strontium/barium, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., which can solve the problem that the filtrate cannot be directly used in front-end production and affects nanocarbon Calcium crystal form and product quality, can not be used and other issues, to achieve the effect of easy control of production quality, good economic benefits, and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0022] In the present invention, a PAM derivative flocculant is added to the calcium carbonate activation tank. Polyacrylamide (PAM) is polymerized from acrylamide monomers. It is a water-soluble linear polymer. It can be mostly ionized in water. It belongs to polymer electrolytes. It is non-dangerous, non-toxic, and non-corrosive. It has good stability when heated to 100°C, and it can be derived from many other substances through hydroxylation reaction, sulfonation reaction, cross-linking reaction, etc.

[0023] The non-polar charged group of the flocculant can neutralize the dynamic potential of the surface of the suspended particles and the impurity ions, reduce the surface energy between the suspended particles and adsorb the impurity ions to make them flocculate, and the polar group can also interact with the polarity of the activator. The groups are cross-linked and entangled to form a three-dimensional network copolymer of calcium carbonate-activator non-polar group-act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com