Supercritical dissolved air cavitation device for reinforcing sludge reduction

A sludge reduction and supercritical technology, which is applied in the oxidation treatment of sludge, sludge treatment, water/sludge/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

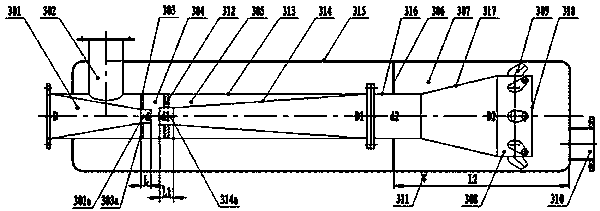

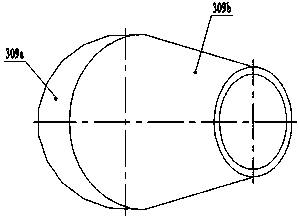

[0017] figure 1 , 2 , 3 shows the structure of a supercritical dissolved air cavitation device. In the figure, the supercritical dissolved air cavitation device includes a jet cavitation generator composed of a contracting nozzle 301 and an air suction pipe 302, a primary diffuser 314 and a target vortex cavitation generator. The jet air generator and the primary diffuser pipe 314 are connected together by the main body inner sleeve 313 , and the main body inner sleeve 313 and the target vortex cavitation generator are arranged in the main body outer sleeve 315 .

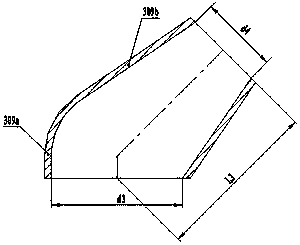

[0018] The shrinking nozzle 301 is provided with a shrinking nozzle throat 301a, and between the shrinking nozzle throat 301a and the inner sleeve 313 of the main body is an air intake regulating plate 303 with 8 vent holes 303a, and the inlet diameter of the shrinking nozzle 301 is D The ratio to the diameter d of the shrinking nozzle throat 301a is 3:1-4:1, and the ratio of the length L of the shrinking nozzle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com