Waterproof coiled material and production method thereof

A waterproof membrane and petroleum asphalt technology, applied in chemical instruments and methods, layered products, building insulation materials, etc., can solve the problems of poor aging resistance, poor bending ability, and high material hardness of coatings, and achieve high temperature resistance and Good low temperature resistance, convenient operation and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

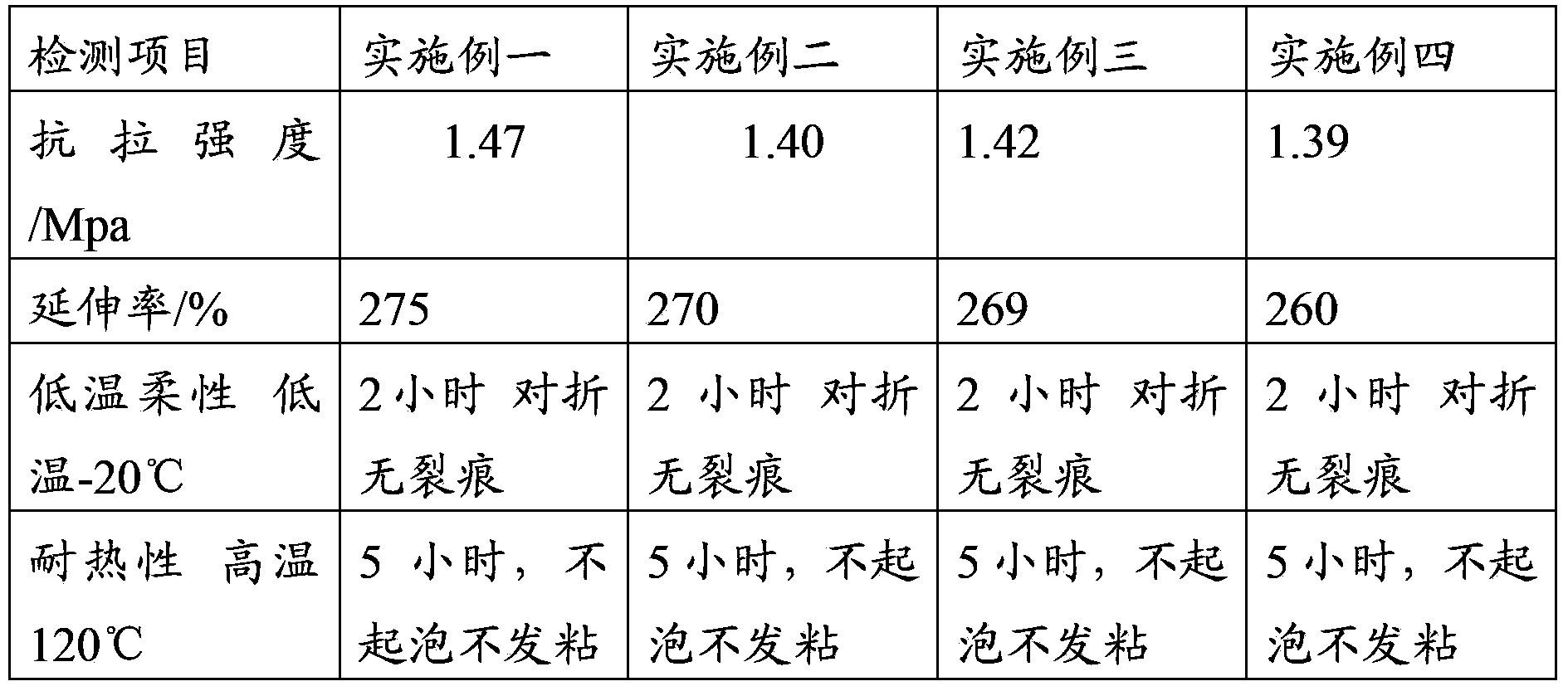

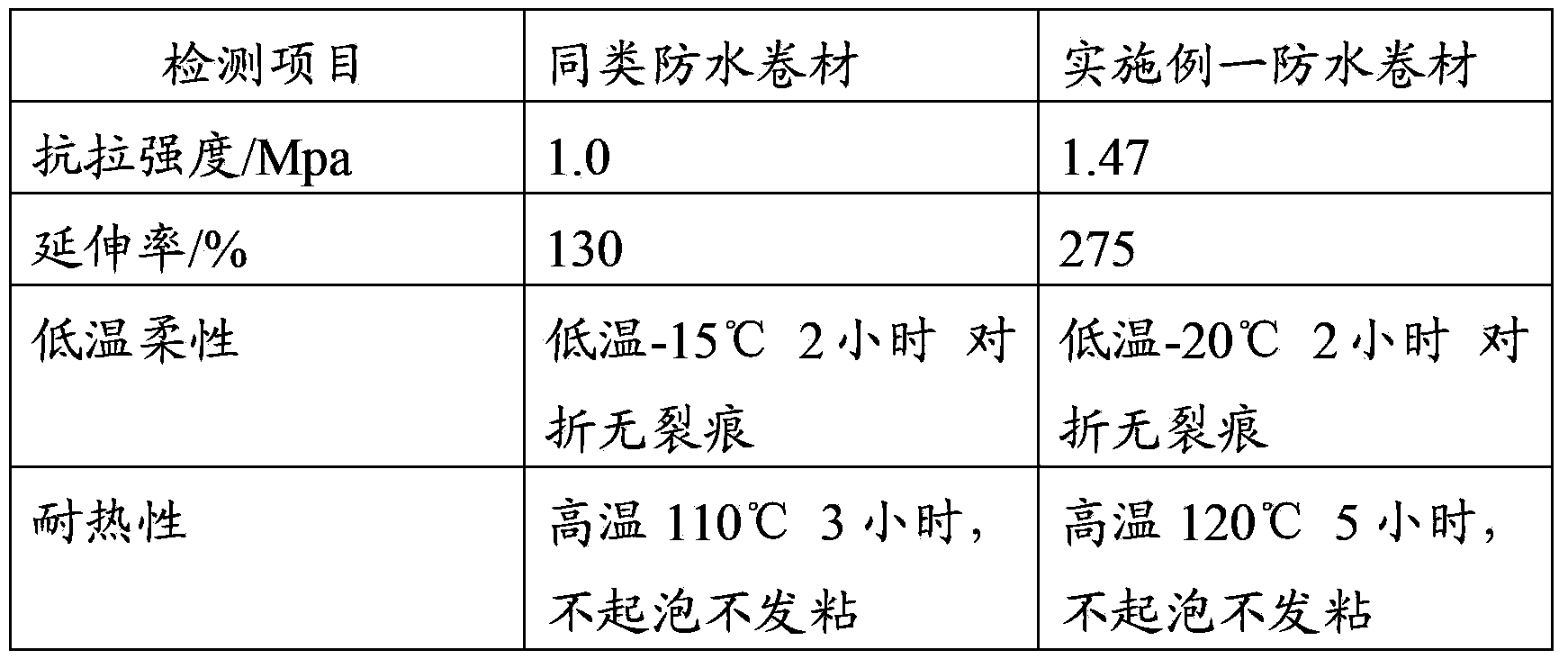

Examples

Embodiment 1

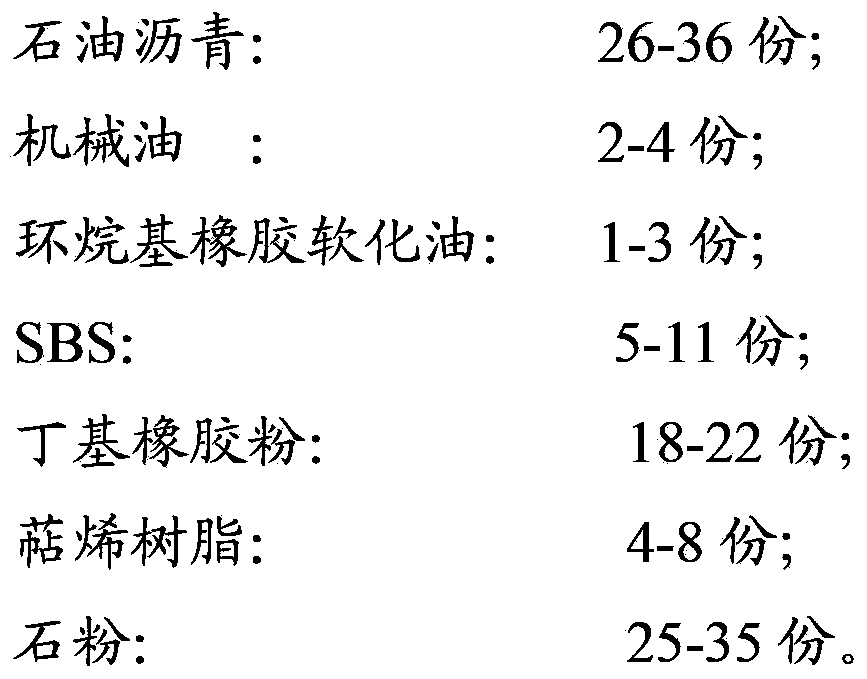

[0021] According to the weight ratio, put 10 parts of 10# petroleum asphalt, 21 parts of 100# petroleum asphalt, 3 parts of machine oil and 2 parts of naphthenic rubber softening oil in the batching tank, and heat it to 230 ° C during the stirring process; then add Stir 8 parts of SBS and 20 parts of butyl rubber powder at 230°C for 2 hours until the butyl rubber powder is fully dissolved and fully integrated with petroleum asphalt, then add 6 parts of terpene resin and stir for 1.5 hours, SBS That is, styrene-butadiene-styrene block copolymer; finally add 30 parts of stone powder and keep stirring at 190°C for 1 hour, then stop heating. The tire base is made of high-strength ultra-thin polyester cloth. At a temperature of 180 ° C, the prepared asphalt is evenly covered on both sides of the ultra-thin polyester cloth on the production line, and the uppermost layer of the asphalt is covered with aluminum foil. The thickness is 2mm. When pasting and constructing, the aluminum f...

Embodiment 2

[0023] According to the weight ratio, put 8 parts of 10# petroleum asphalt, 23 parts of 100# petroleum asphalt, 2 parts of machine oil and 3 parts of naphthenic rubber softening oil in the batching tank, and heat it to 240 ° C during the stirring process; then add Stir 5 parts of SBS and 22 parts of butyl rubber powder at 220°C for 2 hours until the butyl rubber powder is fully dissolved and fully integrated with petroleum asphalt, then add 7 parts of terpene resin and stir for 2 hours, SBS That is, styrene-butadiene-styrene block copolymer; finally add 30 parts of stone powder and keep stirring at 190°C for 1.5 hours, then stop heating. The tire base is made of ultra-thin polyester cloth. At a temperature of 185°C, the prepared asphalt is evenly covered on both sides of the ultra-thin polyester cloth and one side is covered with film. The uppermost layer of asphalt is covered with aluminum foil. The thickness of the waterproof membrane is 1.8mm.

Embodiment 3

[0025] According to the weight ratio, put 12 parts of 10# petroleum asphalt, 18 parts of 100# petroleum asphalt, 1 part of machine oil and 3 parts of naphthenic rubber softening oil in the batching tank, and heat it to 200 ° C during the stirring process; then add 11 parts of SBS and 18 parts of butyl rubber powder, stir at 200°C for 2 hours, until the butyl rubber powder is fully dissolved and fully blended with petroleum asphalt, then add 4 parts of terpene resin and stir for 2 hours, SBS That is, styrene-butadiene-styrene block copolymer; finally add 33 parts of stone powder and keep stirring at 190°C for 1.5 hours, then stop heating. The tire base is made of ultra-thin polyester cloth. At a temperature of 185°C, the prepared asphalt is evenly covered on both sides of the ultra-thin polyester cloth and one side is covered with film. The uppermost layer of asphalt is covered with aluminum foil. The thickness of the waterproof membrane is 1.5mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com