Low-temperature metal lithium distillation equipment and distillation method thereof

A technology of distillation equipment and low-temperature metal, which is applied in the field of low-temperature lithium metal distillation equipment and its distillation, can solve problems such as instability, poor stability, and low vacuum degree, and achieve safe and reliable production and operation, stable product quality, and excellent electrical performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

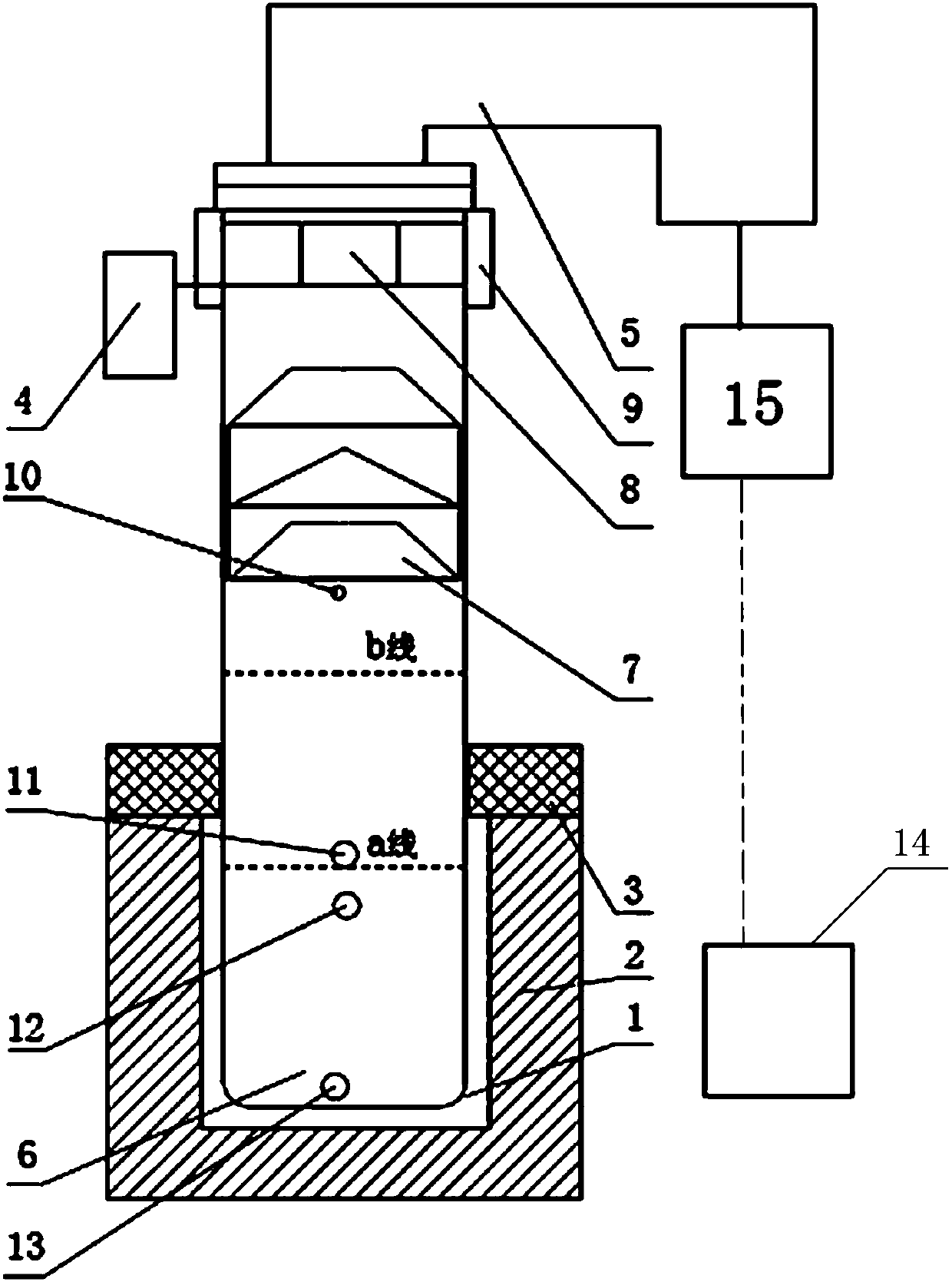

[0036] Embodiment 1: start heating furnace 2 and vacuum pump 15, when furnace temperature reaches 450 ℃, vacuum degree in tank reaches 5 * 10 -4 At pa, add 50kg of industrial-grade lithium metal (Na content 0.2%) through the feed pipe 12. At this time, the liquid level of the material in the distillation tank reaches the line a, the height of the liquid level is equivalent to the height of the heating area, and the upper and lower temperatures of the material are basically equal. After 3 hours of distillation, the impurity metal sodium content in the lithium liquid is between 0.1 and 0.2%, and the effect of removing sodium is not obvious if the time is prolonged.

Embodiment 2

[0037] Embodiment 2: start heating furnace 2 and vacuum pump 15, when furnace temperature reaches 450 ℃, vacuum degree reaches 5 * 10 -4 Pa, add 100kg of industrial-grade lithium metal (Na content 0.2%) through the feed pipe 12, at this time the liquid level of the material in the distillation tank reaches the line b, and the height of the liquid level of the material on the line b is at least 600mm higher than the height of the heating area. The upper and lower temperatures differ by at least 50°C. After 3 hours of distillation operation, the impurity metal sodium content in the lithium liquid is ≤0.005%, and 99.95% of high-purity battery-grade metal lithium is obtained. The lithium liquid material in the distillation tank is discharged through the discharge pipe 11, and at this time, the liquid level of the material in the distillation tank returns to line a. Continue to add 50kg of industrial-grade lithium metal through the feed pipe 12 to carry out the next batch of opera...

Embodiment 3

[0039] Embodiment 3: start heating furnace 2 and vacuum pump 15, when furnace temperature reaches 500 ℃, vacuum degree reaches 5 * 10 -3 Under the condition of pa, add 100kg of high-sodium metal lithium (Na content 1%) through the feed pipe 12. At this time, the liquid level of the material in the distillation tank reaches the line b, and the height of the liquid level of the material on the line b is at least 600mm higher than the height of the heating area. The difference between the upper and lower temperatures of the material is at least 50°C. After 3 hours of distillation operation, the impurity metal sodium content in the lithium liquid was ≤0.02%, and 99.9% battery-grade metal lithium was obtained. The lithium liquid material in the distillation tank is discharged through the discharge pipe 11, and at this time, the liquid level of the material in the distillation tank returns to line a. Continue to add 50kg of high-sodium grade metal lithium through the feed pipe 12 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com