Chemical waste water discharge-free system

A chemical wastewater and circulating water system technology, applied in the waterway system, sewer system, sewage discharge, etc., can solve the problems of increasing chemical wastewater discharge, unfavorable energy saving and emission reduction, increased water consumption, etc., to achieve multiple cycles Utilization, improvement of the surrounding environment, high efficiency of waste water recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

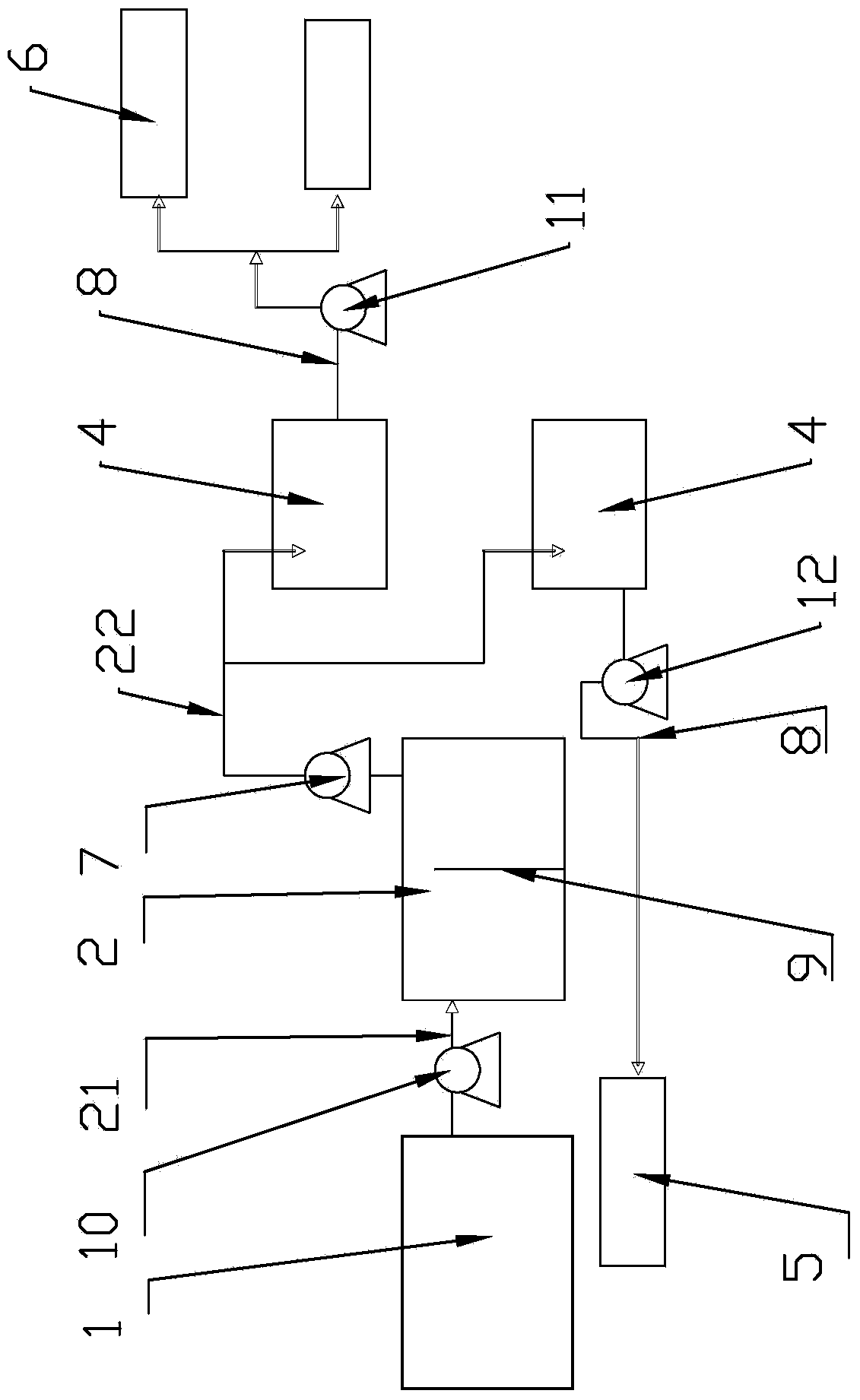

[0013] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

[0014] Such as figure 1 As shown, a kind of chemical waste water of the present invention does not discharge system, and it comprises waste water collection tank 1, secondary sedimentation tank 2, user's reservoir 3, circulating pool 4, circulating water system 5 and user 6, described secondary The sedimentation tank 2 is provided with a water inlet pipe 21 and a water outlet pipe 22 respectively. The water inlet pipe 21 is connected to the waste water collection pool 1, and the waste water collection pool 1 is used to collect industrial waste water generated in each process and store it in a centralized manner. . The lift pump 7 is set on the outlet pipeline 22, and the lift pump 7 lifts the purified water in the secondary sedimentation tank 2 to the user storage tank 3 and the cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com