Double-air-spring comprehensive performance test bench

A comprehensive performance and air spring technology, which is applied in the field of vehicle engineering, can solve the problems of difficult dynamic analysis of air springs, inability to simulate height valves, differential pressure valves and anti-roll torsion bars, etc. The effect of convenient and quick test and low test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

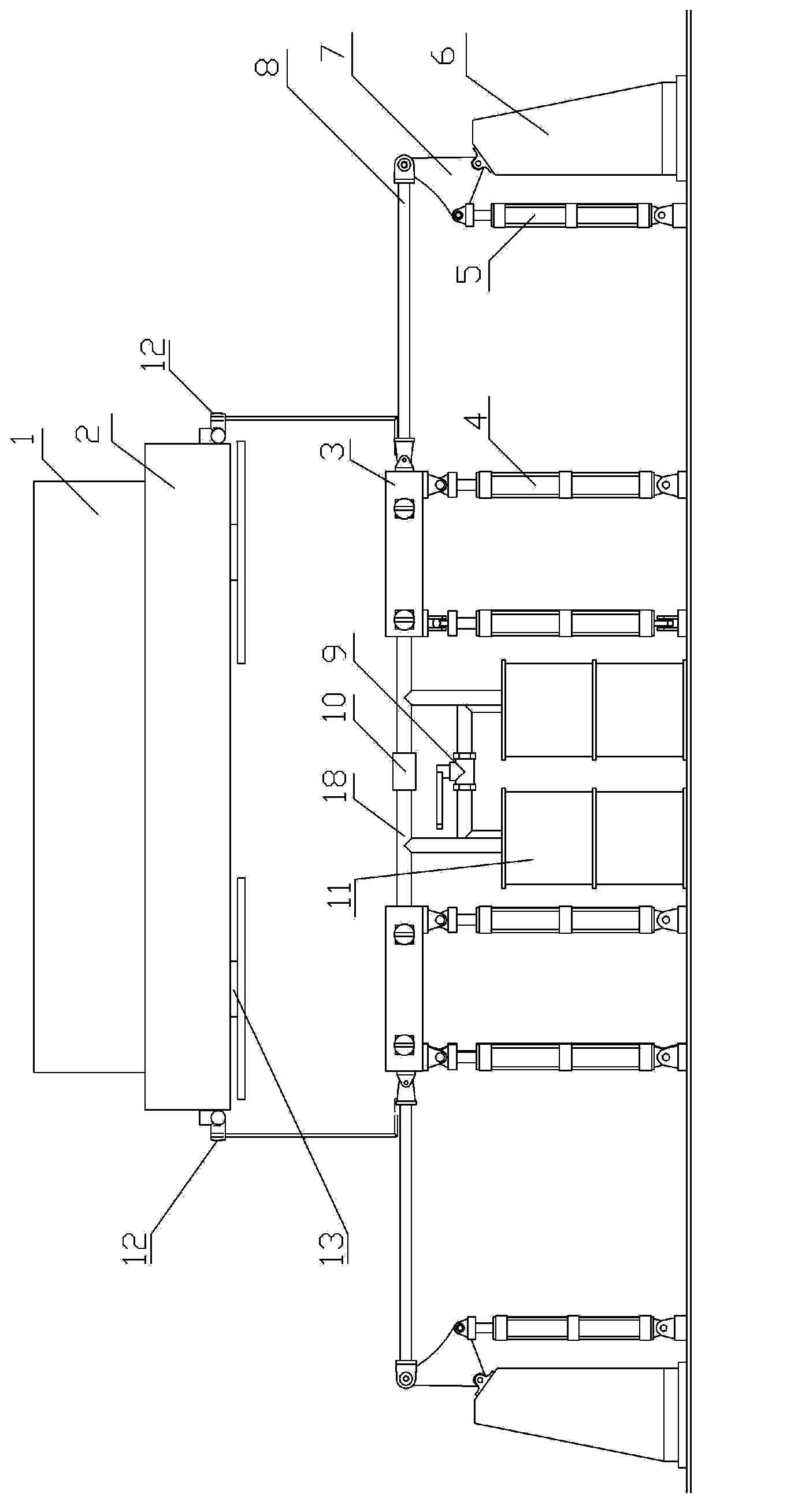

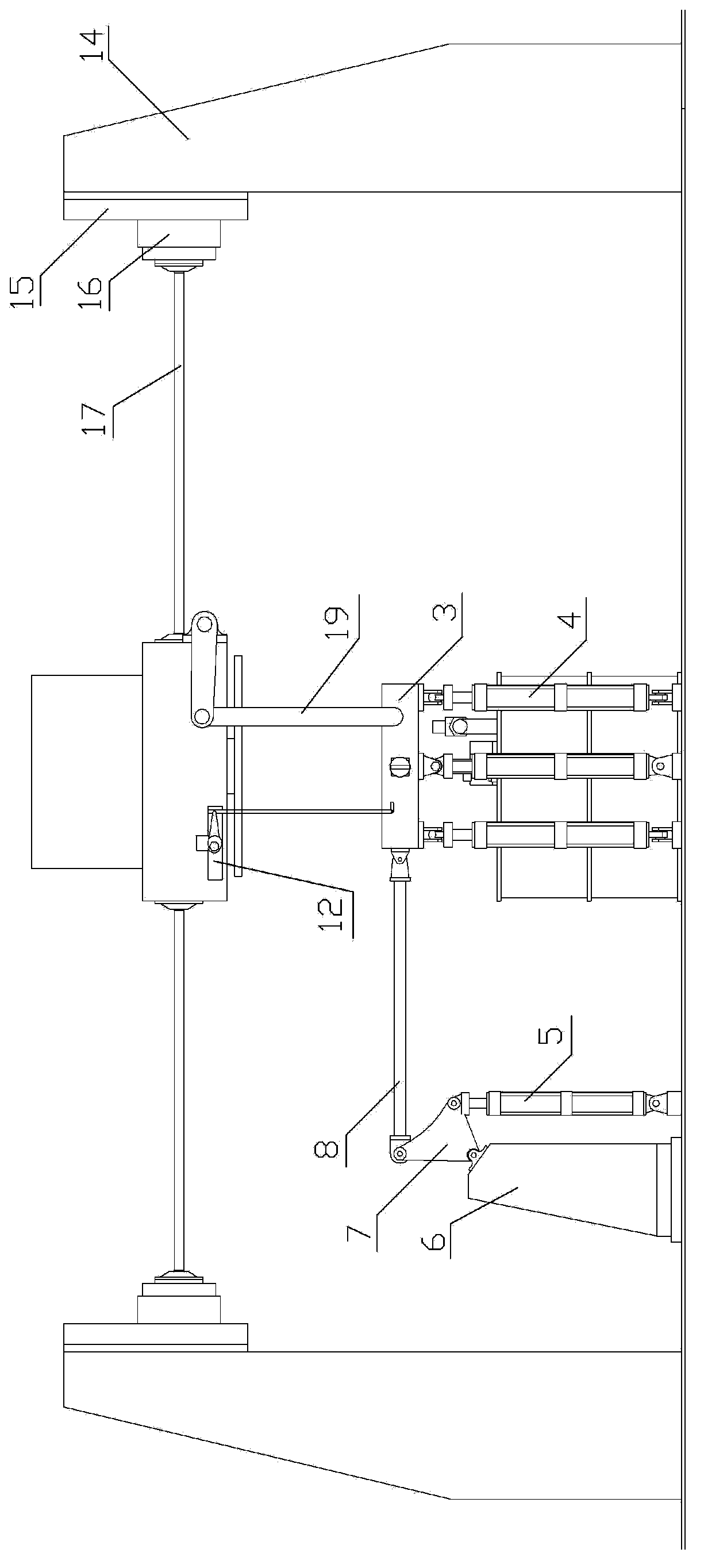

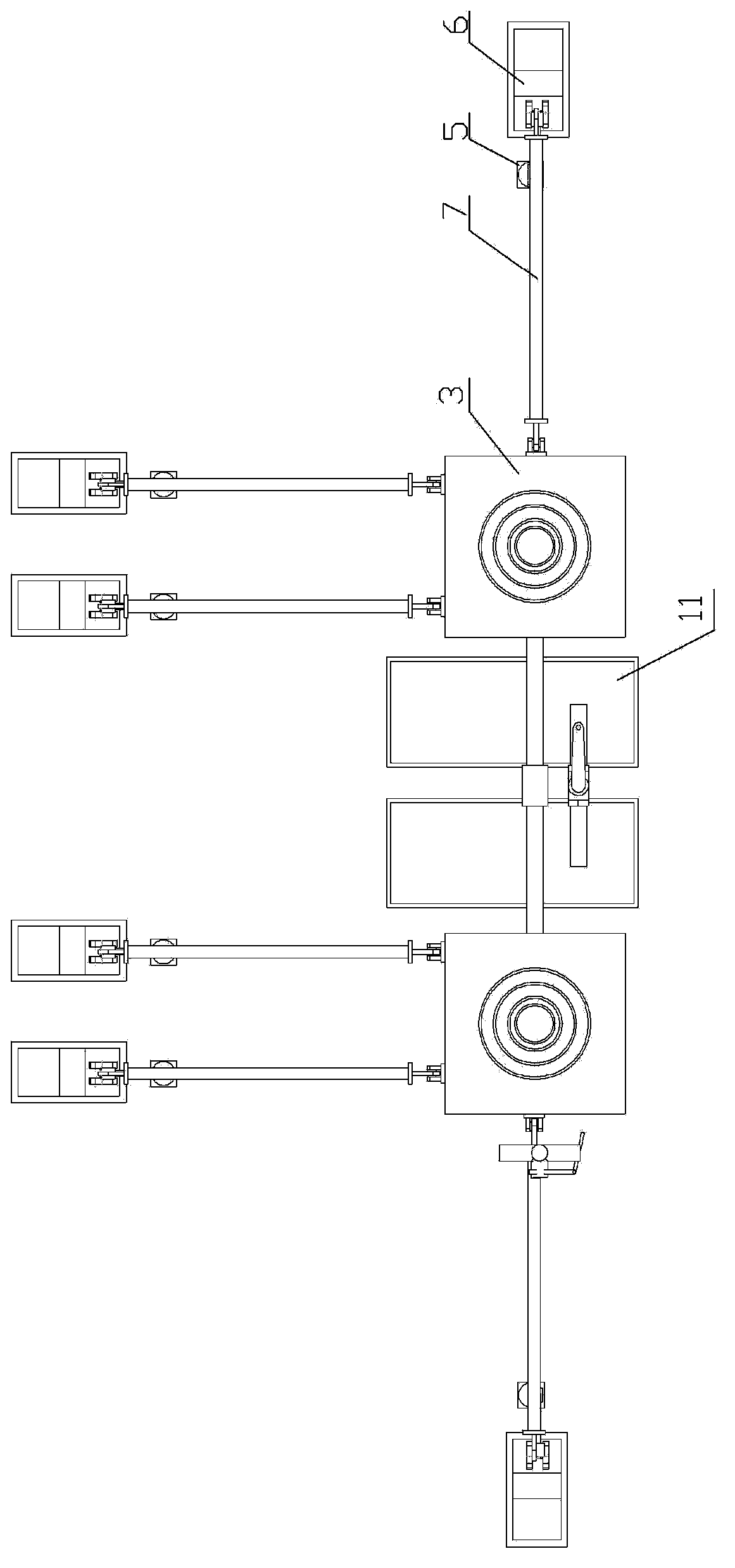

[0027]A dual-air spring comprehensive performance test bench, including an actuation table, an additional air chamber, an inflation and exhaust system, a hydraulic system, a high and low pressure gas storage tank, an external compressor, and an air conditioner. The actuation table has two load-bearing test pieces The workbenches 3 are connected through the pipeline 18 provided with the differential pressure valve 10, each workbench 3 is provided with a vertical excitation loading device, and a lateral excitation loading device and a torsional excitation loading device are provided on the side, they The hydraulic systems are connected respectively; the counterweight device is composed of grid 1 and bearing platform 2, and the quality of the counterweight is determined by the quality and quantity of lead blocks in the grid, which can simulate the mass and moment of inertia of the actual car body. One end of the double ball hinge connecting rod 17 is fixed to the bearing platform ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com