Multi-inlet single-cavity type hot diaphragm cooling device for ground-based solar telescope

A solar telescope and cooling device technology, applied in telescopes, optics, optical components, etc., can solve problems such as low sealing reliability, high processing difficulty, and low cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

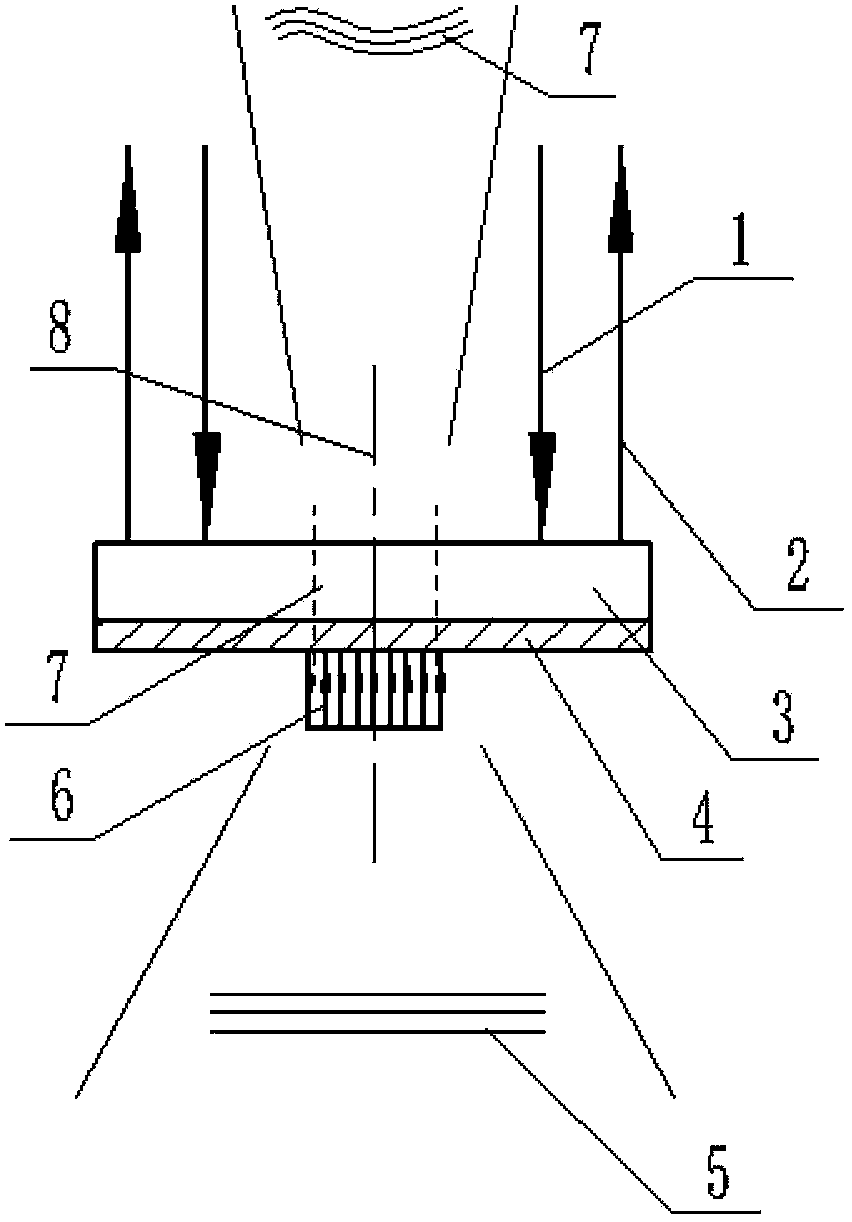

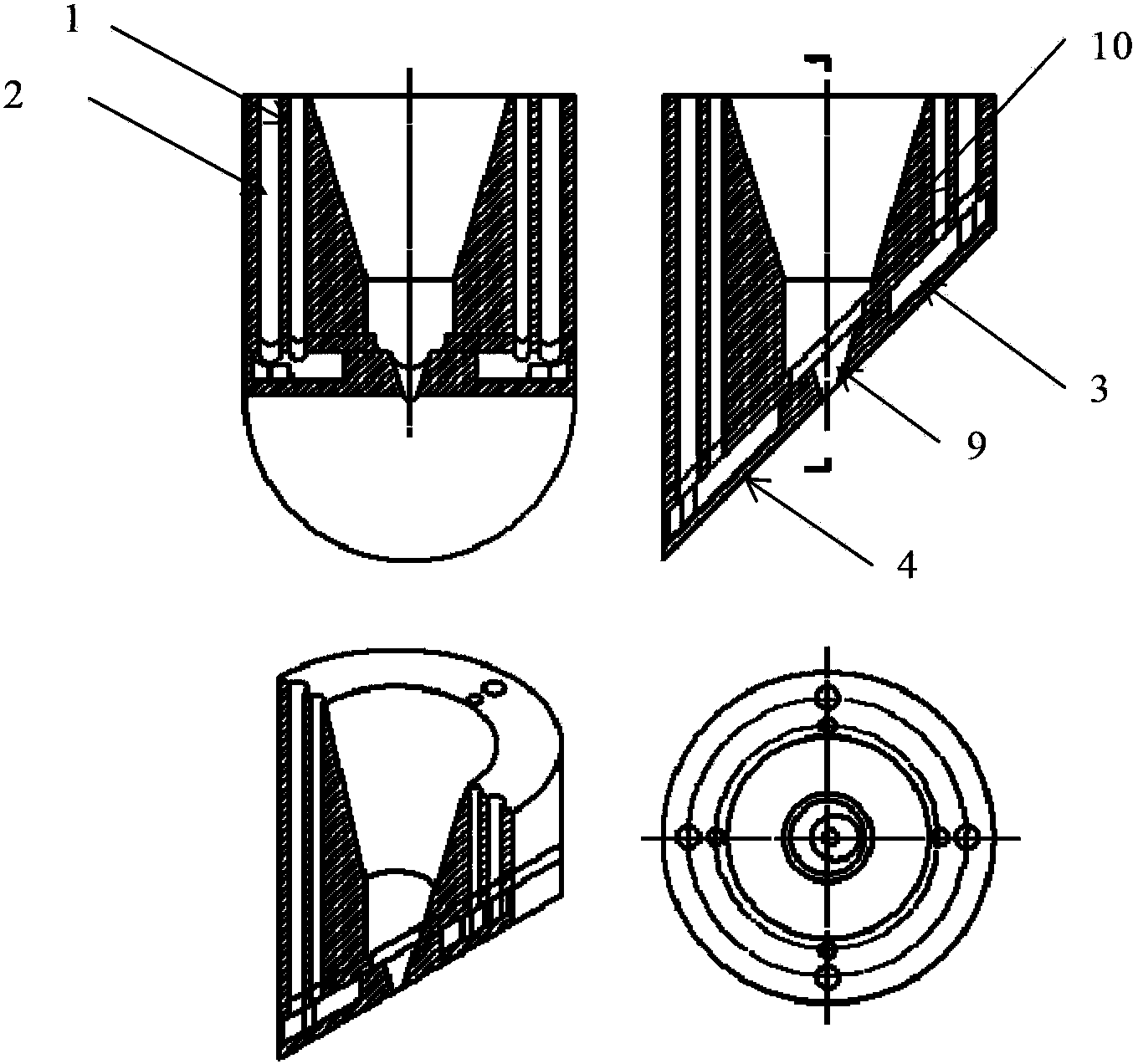

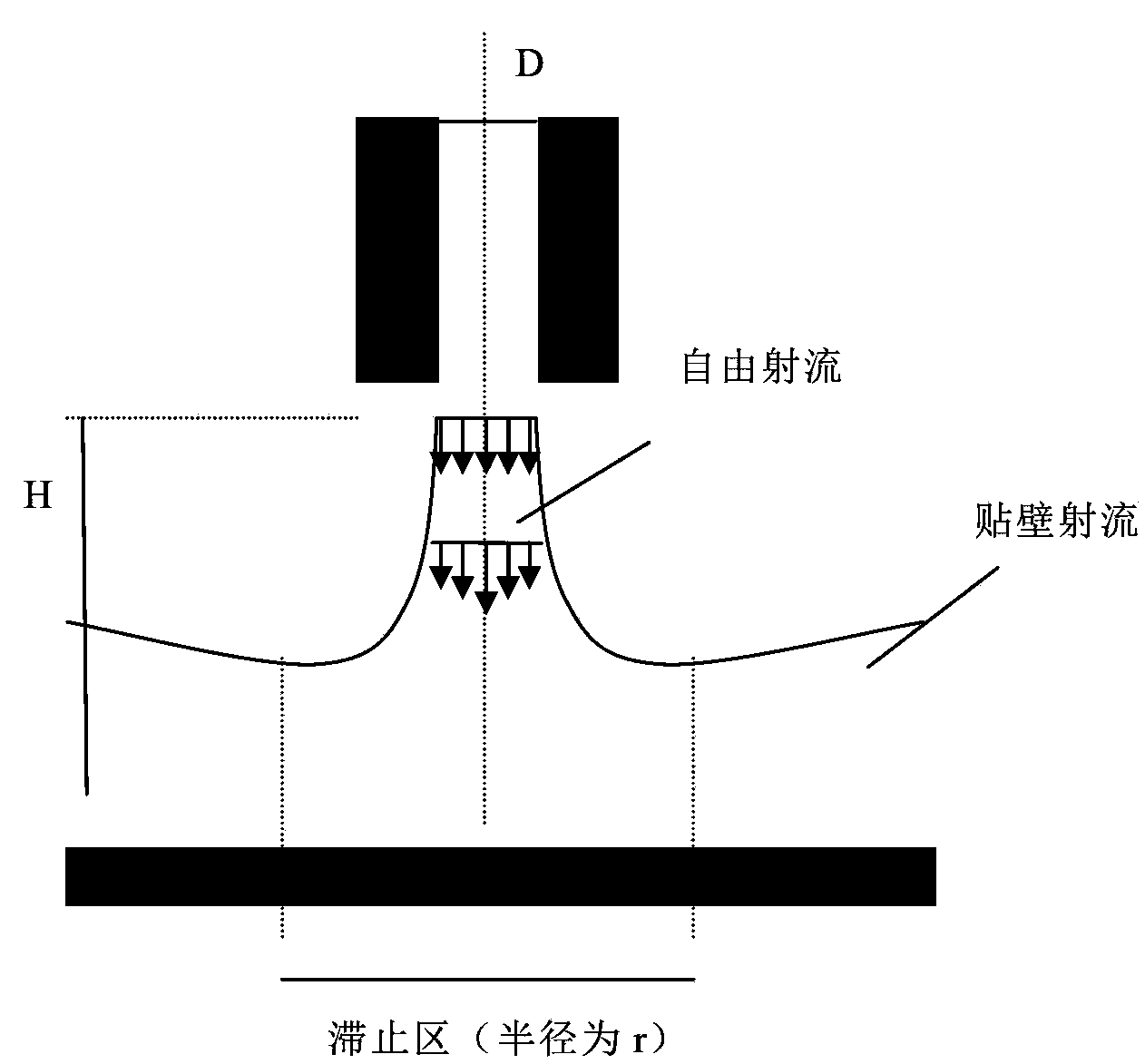

[0037] like figure 1As shown, the present invention is a multi-entrance single-cavity thermal diaphragm cooling device for ground-based solar telescopes, which consists of a liquid inlet pipe 1, a liquid outlet pipe 2, a cooling chamber 3 and a diaphragm reflection panel 4. First, the constant temperature cooling liquid Enter the cooling chamber 3 from the liquid inlet pipe 1, and then, due to the obstruction of the back wall of the diaphragm reflective panel 4, the high-speed liquid flow flowing in from the liquid inlet pipe 1 forms a circular hole jet, and the center of the liquid inlet pipe has a certain radius. In the circular domain of , the fluid and the wall have a relatively high velocity. According to the principle of jet cooling, a large heat transfer coefficient is generated in this circular area (called "jet cooling area"), forming a jet cooling with extremely high heat transfer efficiency, which can convert the All the heat absorbed by the diaphragm reflective p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com