A drive circuit for a source-controlled constant-current output power supply regulated by load voltage

A constant current output and drive circuit technology, applied in the direction of irreversible AC power input conversion to DC power output, etc., can solve the problem that individual differences of flyback transformers cannot be corrected, the accuracy and consistency of constant current control are difficult to guarantee, and the lack of load terminals Signal feedback and other issues to achieve the effect of improving relative consistency, expanding dynamic range, and ensuring independence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

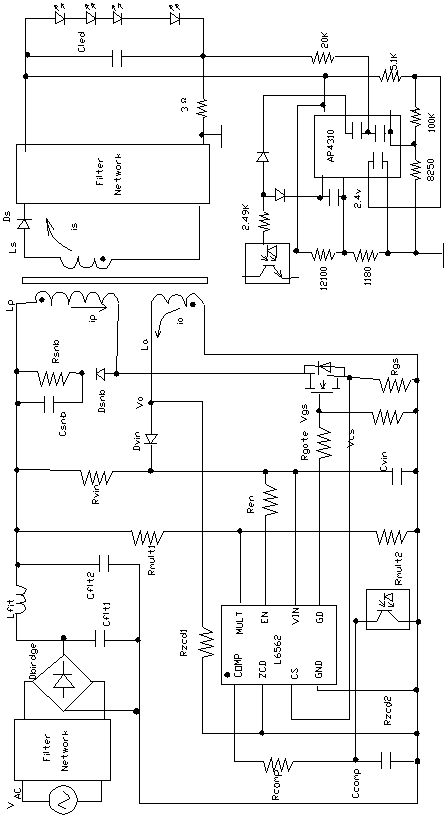

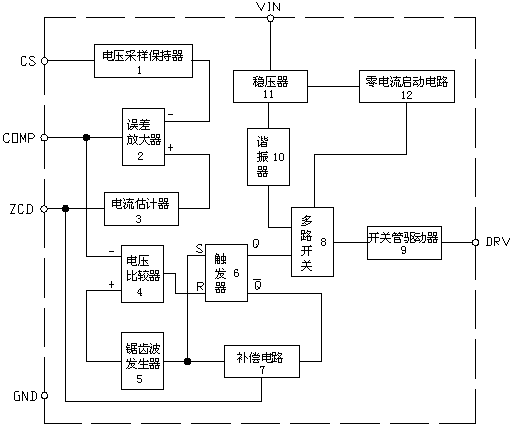

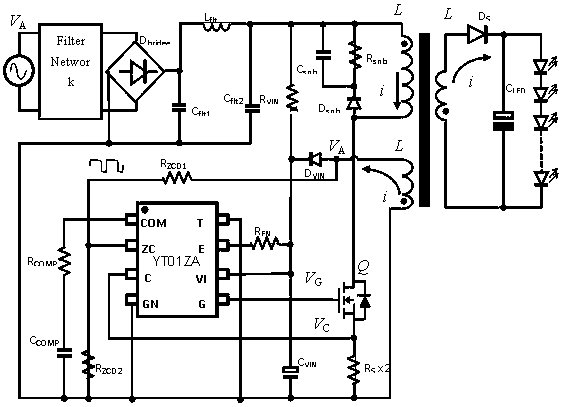

[0018] see Figure 2~3 , the present invention relates to a drive circuit for controlling a constant current output power supply at the source of load voltage regulation, the circuit includes a voltage sampler and holder 1, an error amplifier 2, a current estimator 3, a voltage comparator 4, and a sawtooth wave generator device 5, flip-flop 6, compensation circuit 7, multi-way switch 8, switch tube driver 9, resonator 10, voltage regulator 11 and start-up circuit 12, the voltage sample holder 1 will input the signal from the CS port of the chip Input the inverting input terminal of the error amplifier 2, the current estimator 3 inputs the signal input from the ZCD port of the chip to the non-inverting input terminal of the error amplifier 2, and the output terminal of the error amplifier 2 is connected to the COMP port of the chip, The signal input by the ZCD port of the chip is input to the compensation circuit 7, the output terminal of the compensation circuit 7 inputs the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com