Metal part thermal forming two-man ladle mechanical arm

A technology of thermoforming and metal parts, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of cold insulation, slow casting speed, low safety, etc., and achieve easy-to-learn system operation, increase the speed of molten iron transportation, The effect of reducing personal safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

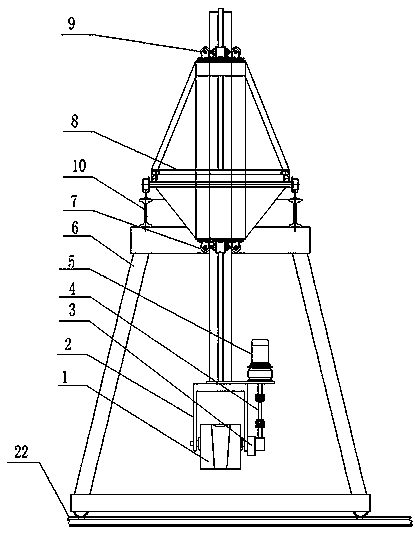

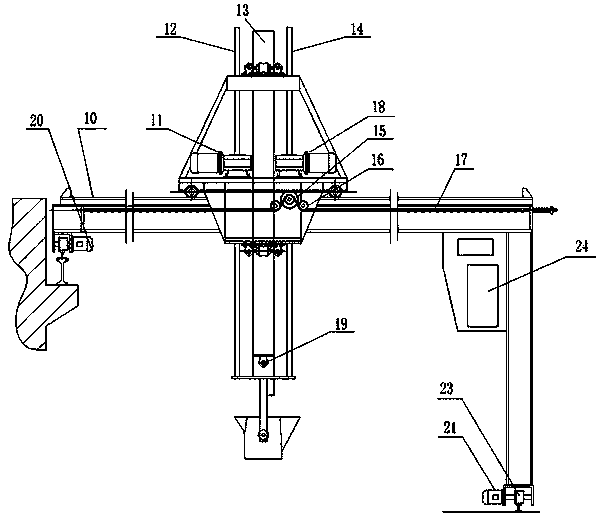

[0032] Embodiment 1, a kind of manipulator for ladle carrying by thermoforming of metal parts, comprises mechanical arm, program-controlled box 24 and gantry 6, and mechanical arm is installed on gantry 6, and program-controlled box 24 is fixed on the side wing of gantry 6, and mechanical arm and program-controlled Case 24 is electrically connected, and moving guide rail 22 is set below gantry 6, and gantry 6 is also provided with gantry moving left servo motor 20, gantry moving right servo motor 21, gantry pulley 23, and there are two pairs of gantry pulleys 23 here, A pair of installation positions are on the top, and the other pair is on the bottom. The gantry pulley 23 can slide on the moving guide rail 22, so that the gantry 6 moves left and right along the moving guide rail 22, and the positions of the cabinet 8 and the ladle 1 are adjusted.

[0033] The mechanical arm includes a ladle lifting mechanism, a ladle horizontal rotation mechanism, a ladle vertical rotation mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com