Plywood type front edge structure of flying machine

An aircraft and leading edge technology, which is applied in the field of the leading edge structure of the aircraft, can solve the problems of uneven temperature distribution in the spanwise direction of the leading edge surface, affecting the effect of structural dredging and heat protection, and low system reliability, and achieves simple structure and reliability. High, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

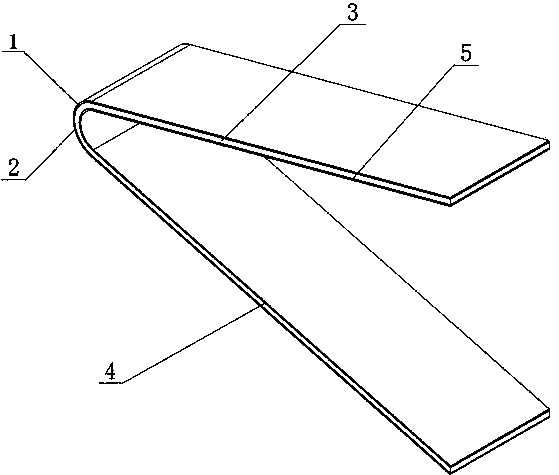

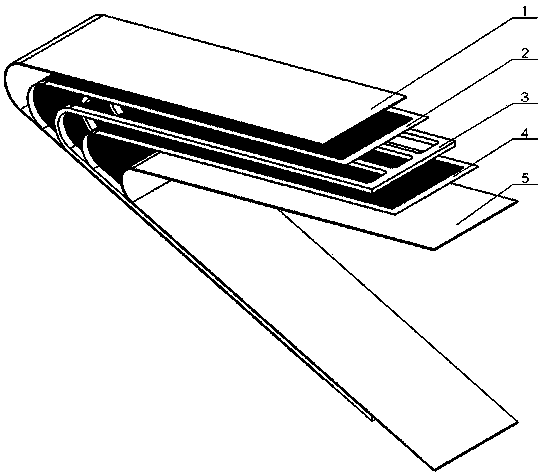

[0021] Such as figure 1 , figure 2 Shown, a kind of laminate type leading edge structure of aircraft, this leading edge structure comprises outer layer skin plate 1, inner layer cladding plate 5, is located between the outer layer skin plate 1 and the inner layer cladding plate 5 for supply The flow channel combination plate for the circulating flow of heat-conducting working medium; the flow channel combination plate is formed by stacking the outer layer capillary channel plate 2, the middle layer flow channel plate 3 and the inner layer capillary channel plate 4 in order from outside to inside, that is The leading edge structure of the entire aircraft is composed of outer skin plate 1, outer capillary channel plate 2, middle layer channel plate 3, inner capillary channel plate 4 and inner cladding plate 5 in order from outside to inside. Pressed and welded by diffusion welding.

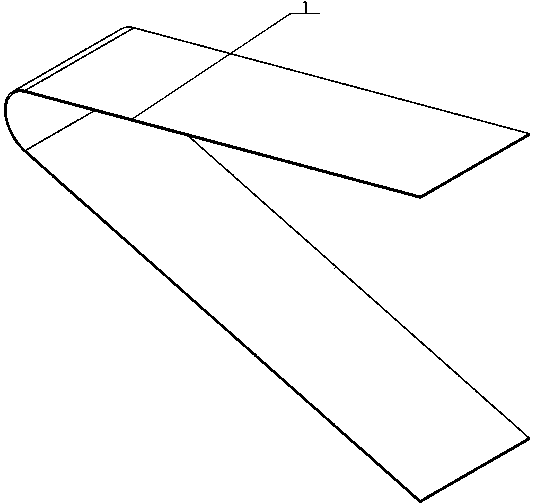

[0022] Such as image 3 As shown, the outer skin panel 1 is a whole panel whose panel shape ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com