Magnesium-smelting operation unit

A magnesium smelting and unit technology, which is applied in the field of operating units dedicated to the vertical tank regenerative reduction furnace of magnesium smelting, can solve the problems of wasting material storage space, large capacity of the silo, and bulky silo, and achieve reliable feeding quality and guarantee Completeness, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

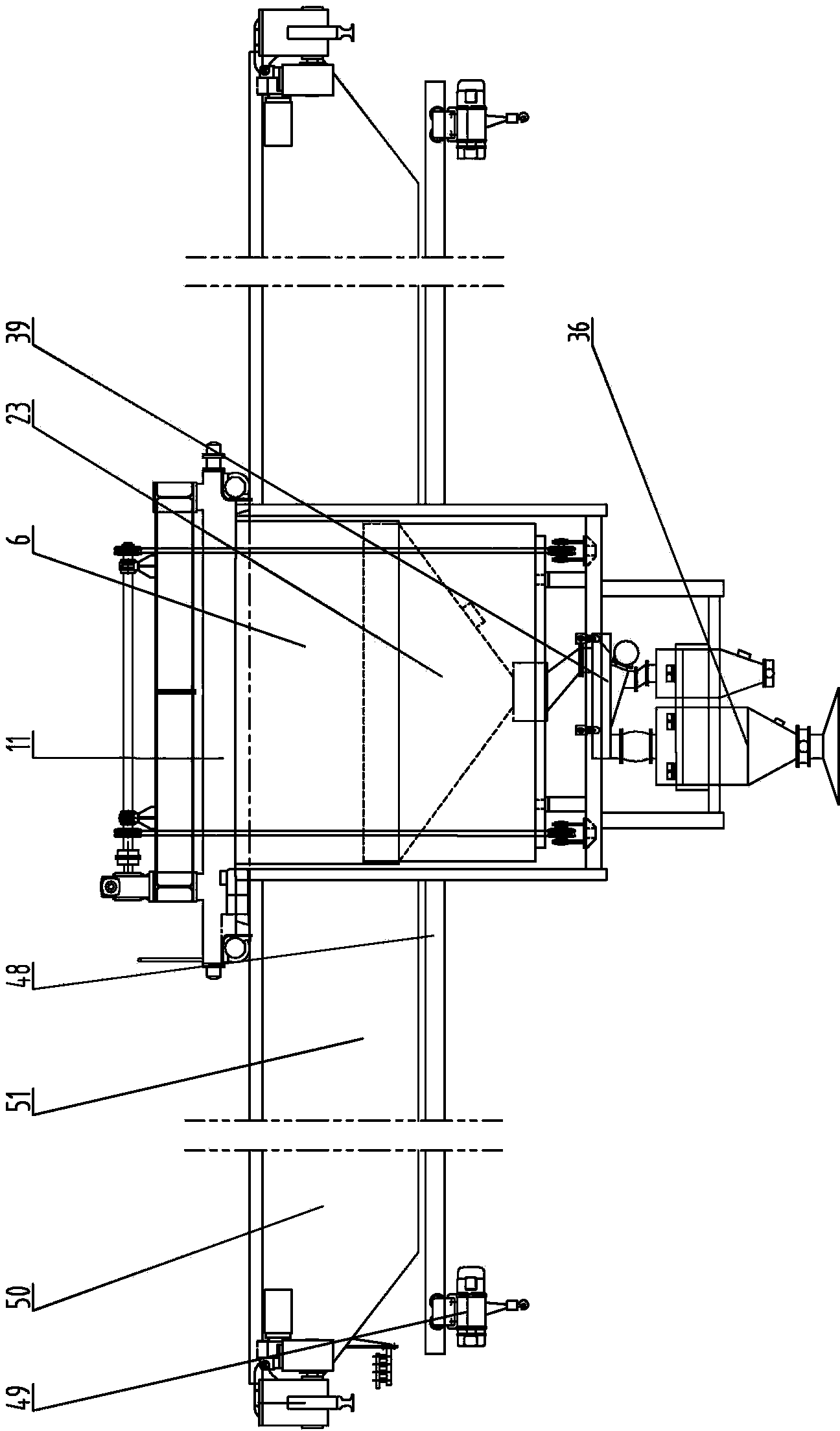

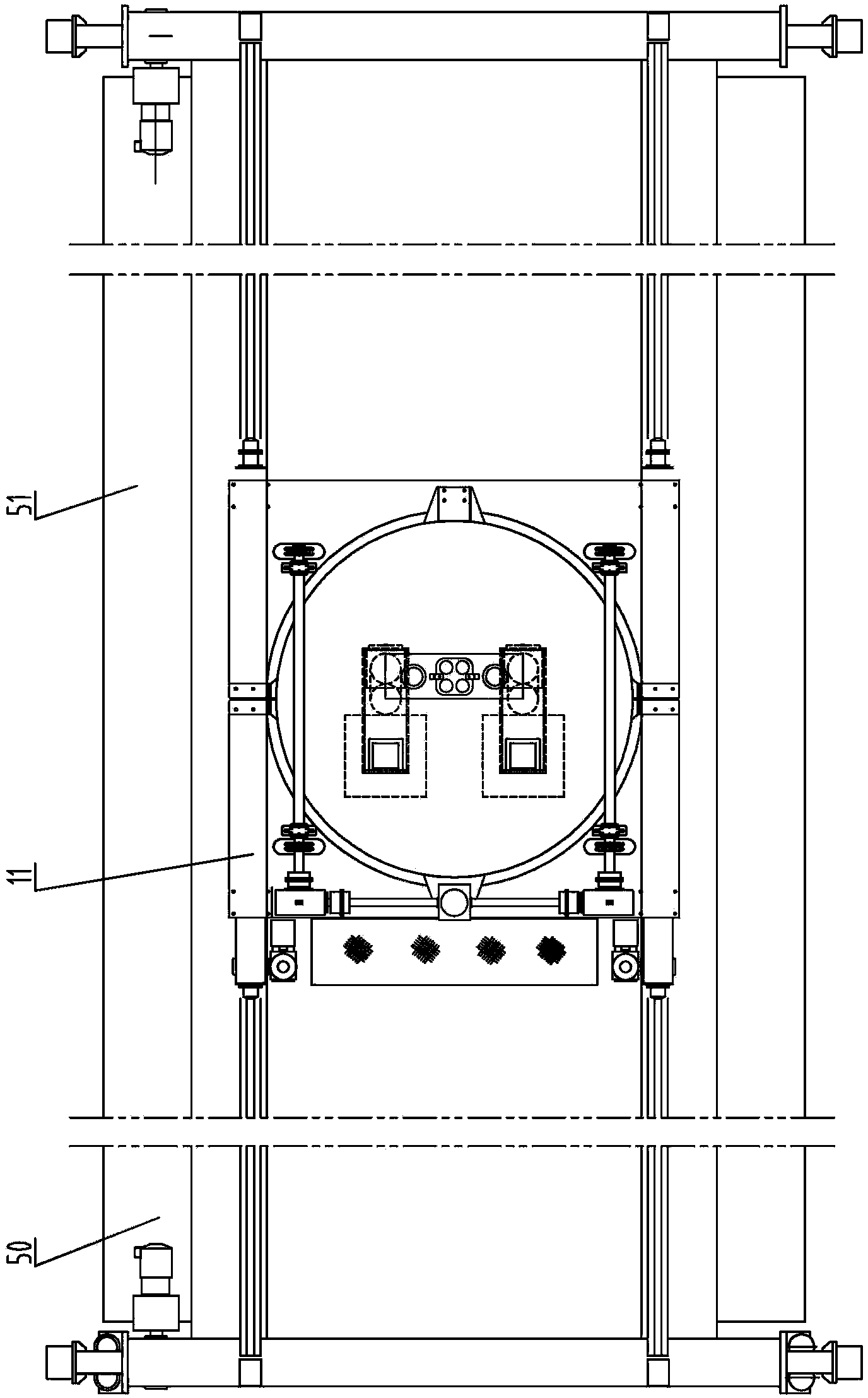

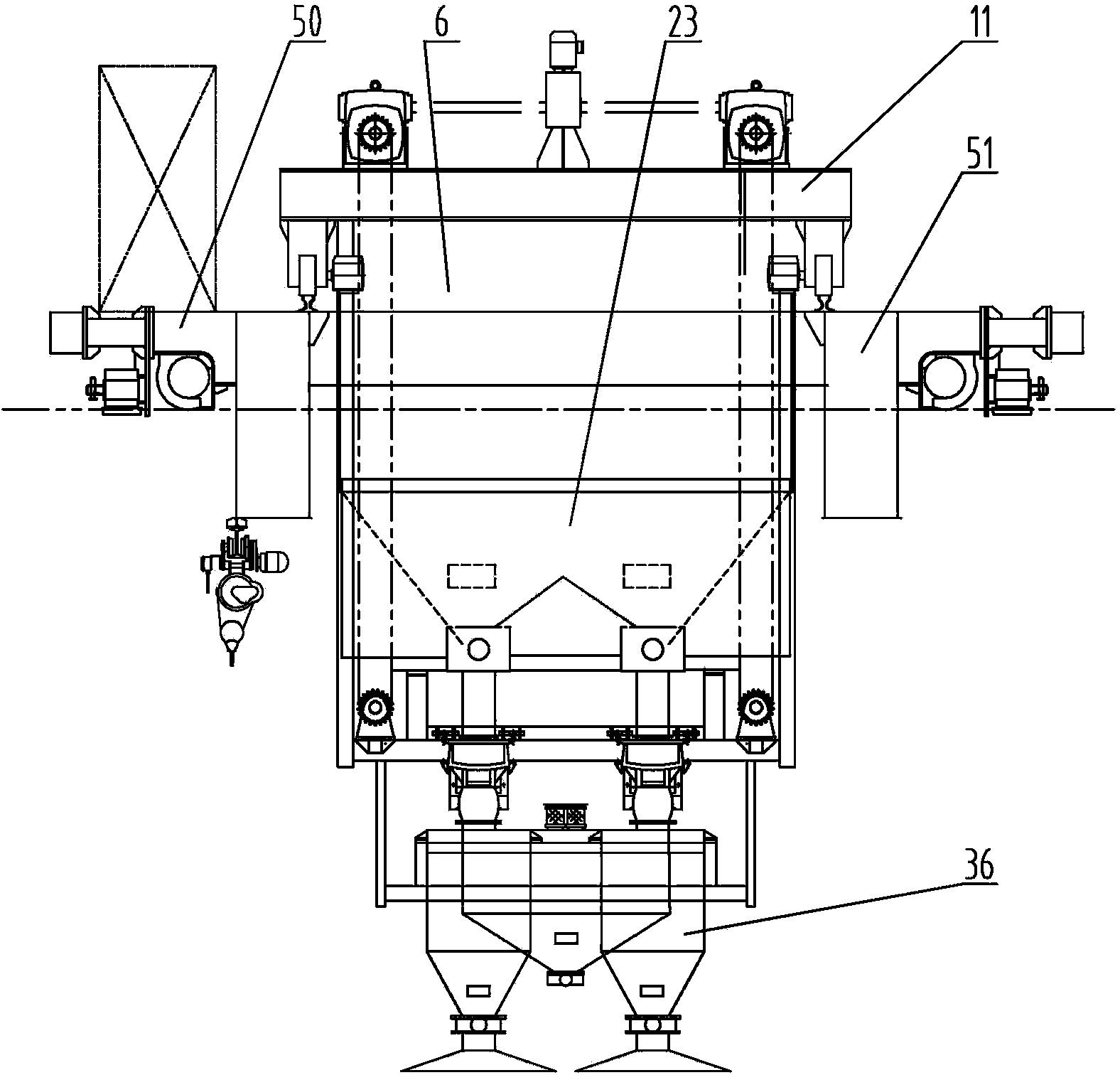

[0039]The present invention comprises longitudinal travel cart 50, and longitudinal travel cart 50 is provided with crossbeam 51, and crossbeam 51 is provided with transverse travel trolley 11; Crossbeam 51 bottom is provided with transverse track 48, and electric hoist 49 is arranged on transverse track 48; A frame 7 is arranged on the horizontal walking trolley 11, and a cylindrical upper feed bin 6 is arranged on the frame 7, and the upper feed bin 6 is provided with a lower feed bin 23 whose top is an opening and the bottom is an outlet; The warehouse 23 is arranged on the frame 7 through the lifting mechanism 12; the bottom frame 7 is provided with a lower frame 38, and the lower frame 38 is provided with a quantitative feed bin 36; the quantitative feed bin 36 and the outlet of the lower feed bin 23 pass through The flexible connection 40 is provided with a vibrating screen material box 39 .

[0040] As a preferred solution of the present invention, two electric hoists 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com