a diesel filter

A diesel filter and filter element technology, which is applied in the directions of machines/engines, engine components, liquid fuel feeders, etc., can solve the problems of poor separation effect and low oil-water separation rate, and achieves simple and convenient use and high degree of informatization. , good filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

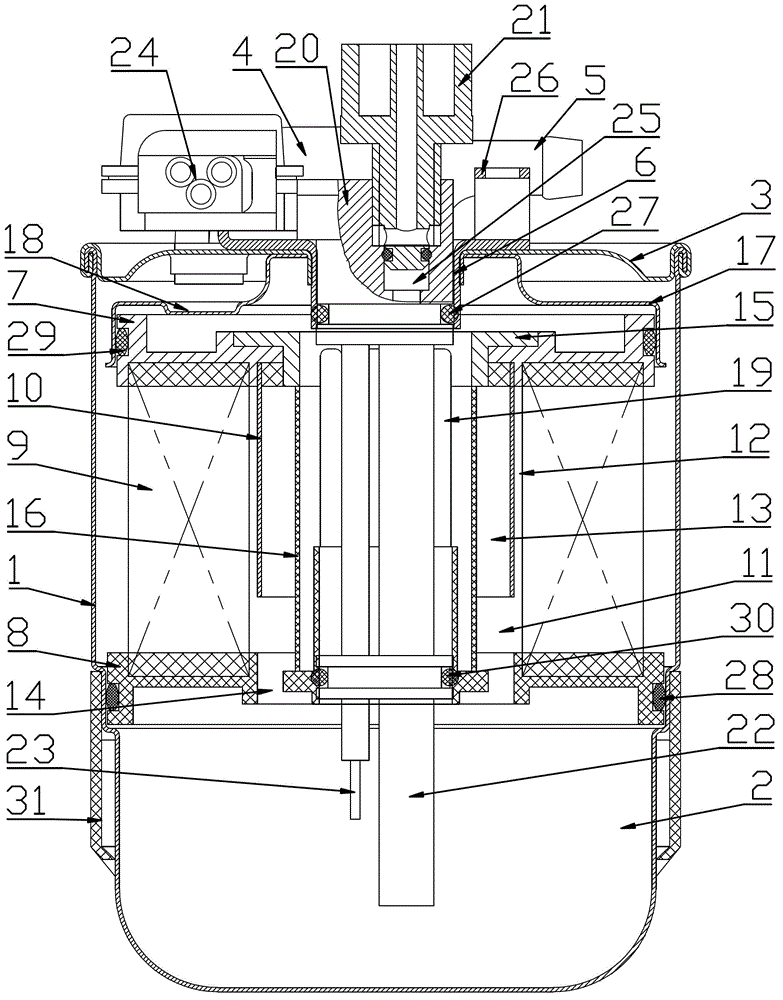

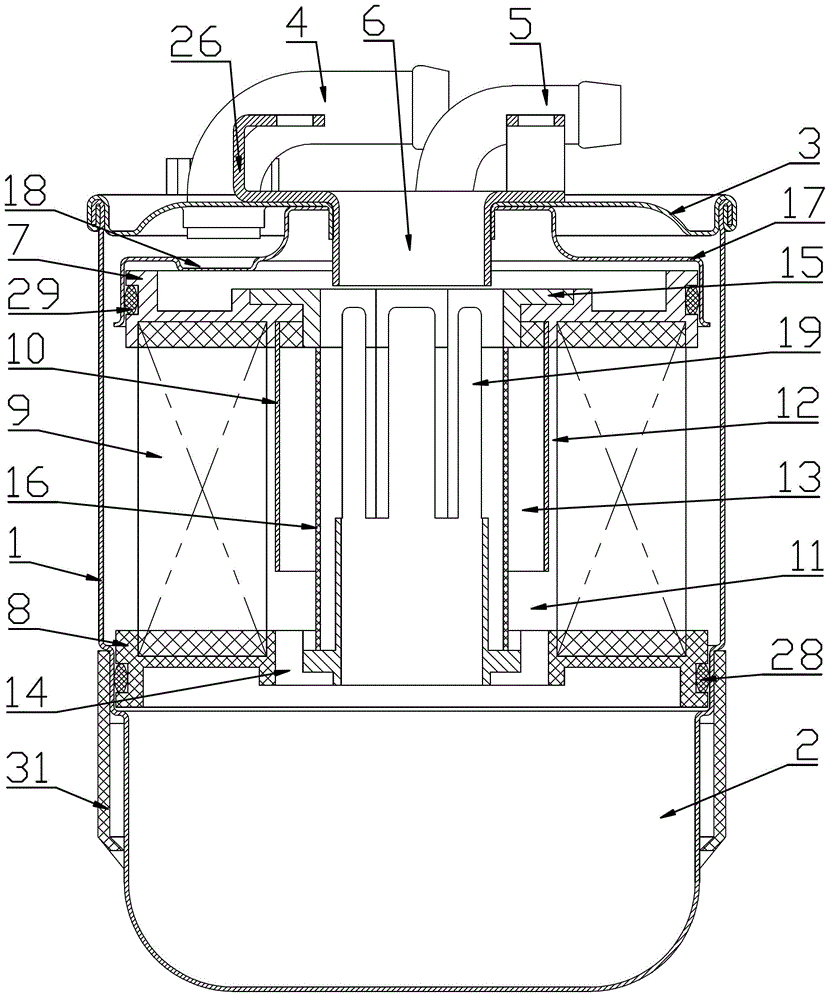

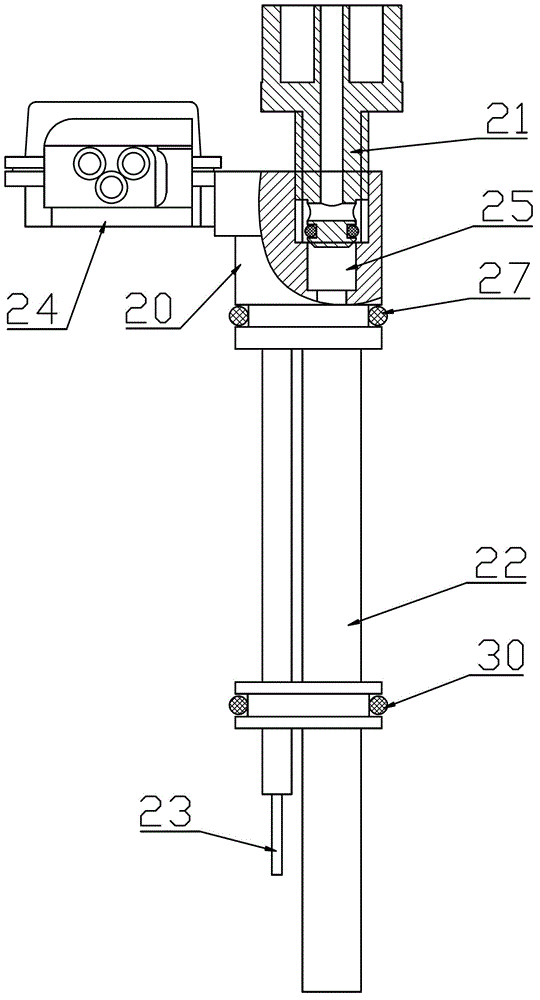

[0024] As attached to the manual figure 1 , 2As shown, a diesel oil filter includes a shell 1 with one end open, a cylindrical filter element is arranged inside the shell 1, a water storage bin 2 located below the filter element is arranged inside the shell 1, a sealing cover 3 is connected to the open end of the shell 1, The sealing cover 3 is provided with an oil inlet pipe 4 and an oil outlet pipe 5, a central hole 6 is provided on the sealing cover 3, and a water release device is arranged in the center hole 6, and the end of the water release device extends to the water storage bin 2, and a positioning Plate 17, the positioning plate 17 is arranged below the sealing cover 3, the filter element includes an upper end cover 7, a lower end cover 8 and an upper connecting plate 15, one end of the positioning plate 17 is in contact with the sealing cover 3, and the other end of the positioning plate 17 is in contact with the upper end cover 7 are closely fitted, and the middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com