A Method for Ultrasonic Detection of Bonding State of Steel Tube Concrete

A technology of concrete-filled steel tubes and bonding state, which is applied in the direction of using sonic/ultrasonic/infrasonic waves to analyze solids, processing response signals of detection, instruments, etc. The effect of saving manpower and material resources, reducing the intensity of manual inspection, and intuitive results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

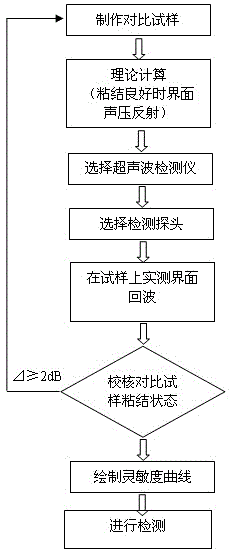

[0033] like figure 1 As shown, the invention discloses a method for ultrasonic testing of the bonded state of steel pipe concrete,

[0034] (1) Make a comparison sample with the same specification as the object to be inspected: the comparison sample uses a steel pipe with the same thickness and the same or similar acoustic performance as the object to be inspected, and concrete with the same composition as the object to be inspected. The same process as the object to be tested is used to bond the two together, so that the comparison sample has two bonding states: a well-bonded area and a completely delaminated area;

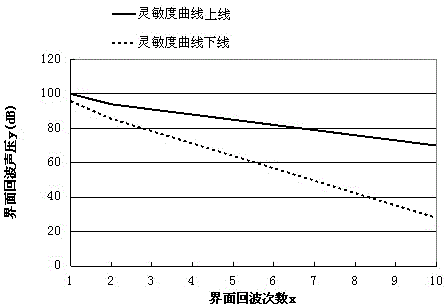

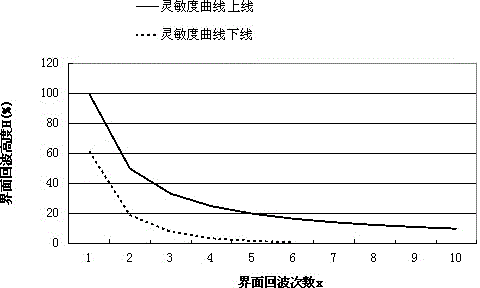

[0035] (2) Check whether the comparison sample can be used: use a digital ultrasonic detector, place the detection probe on the side of the steel pipe in the well-bonded area, and keep a good coupling with the steel pipe; adjust the gain knob of the instrument to reduce the amplitude of the sound pressure of the first interface echo When the reference wave height ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com