Super-resolution confocal microimaging method and device based on column polarization vortex beam

A confocal microscopic imaging and vortex beam technology, which is applied in the field of super-resolution confocal microscopic imaging, can solve the problems of limited ability to improve resolution, insignificant effect, and inability to infinitely reduce the wavelength of incident light.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

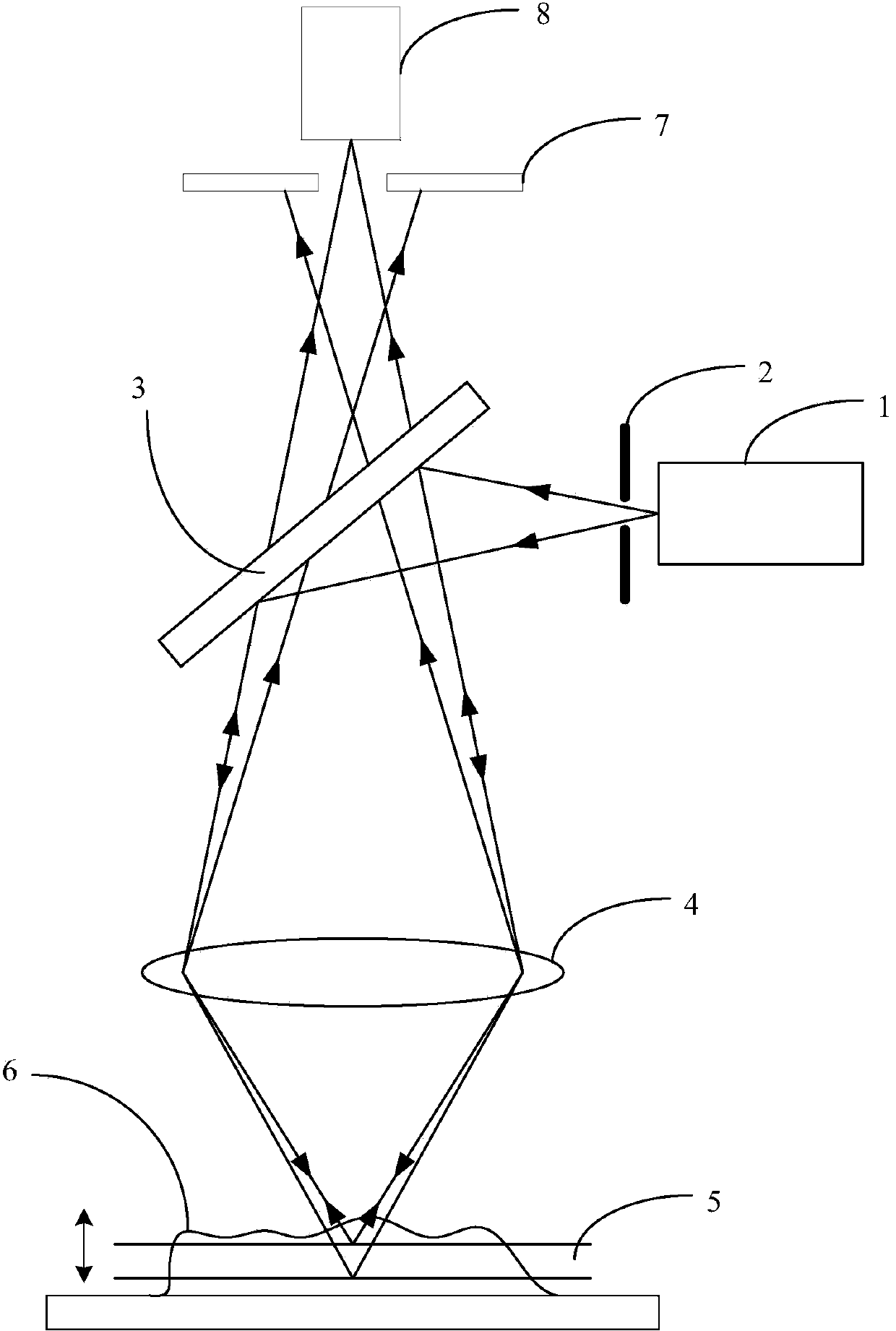

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited thereto.

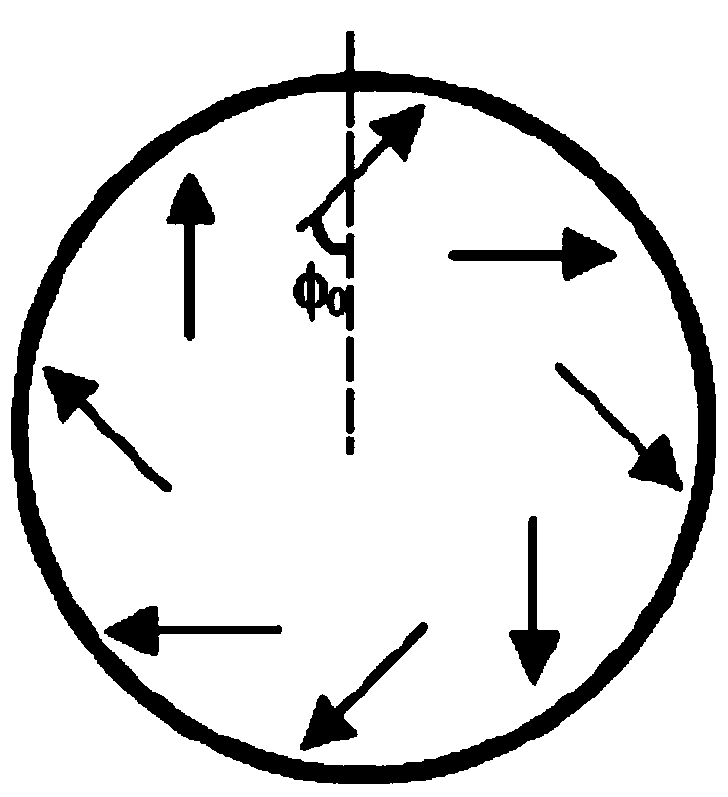

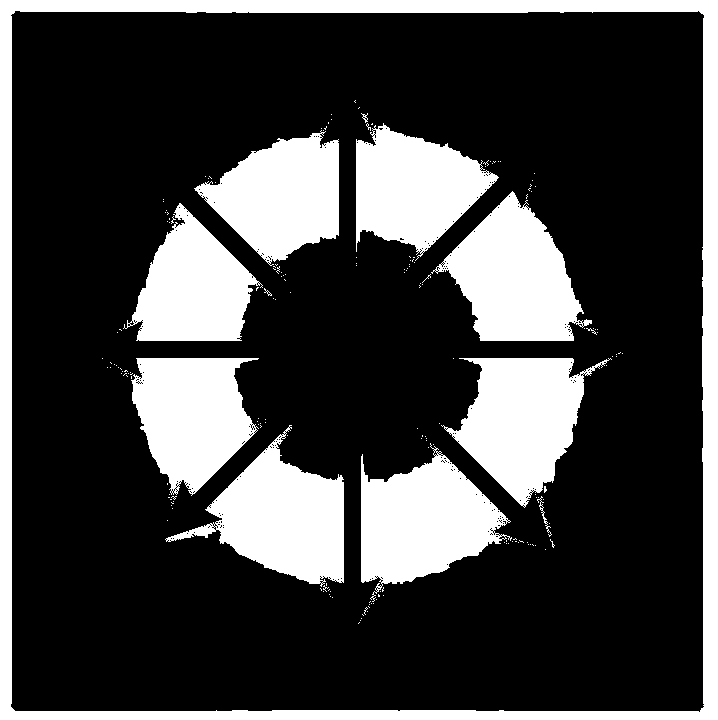

[0020] Figure 2(a)-Figure 2(d) is the polarization distribution characteristics on the cross-section of the cylindrical vector beam, where Figure 2(a) is the initial azimuth angle φ 0 The cylindrical vector beam of Fig. 2 (b) is a radially polarized beam, Fig. 2 (c) is a tangentially polarized beam, and Fig. 2 (d) is a method for obtaining a vortex beam using a vortex phase plate.

[0021] As shown in Figure 2(a), a cylindrical vector beam is a kind of polarized beam whose polarization state on the beam cross section has cylindrical symmetry characteristics with respect to the beam propagation axis. In the local part of the beam cross section, the polarization state of the beam is linearly polarized , but its polarization direction varies spatially. When the initial polarization azimuth angle φ0 of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com