Optimization method for photoresist layer of guide mode resonance optical filter

A photoresist layer, guided mode resonance technology, applied in the direction of filters, microlithography exposure equipment, photolithography process exposure devices, etc., can solve the problem of no filter, etc., and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

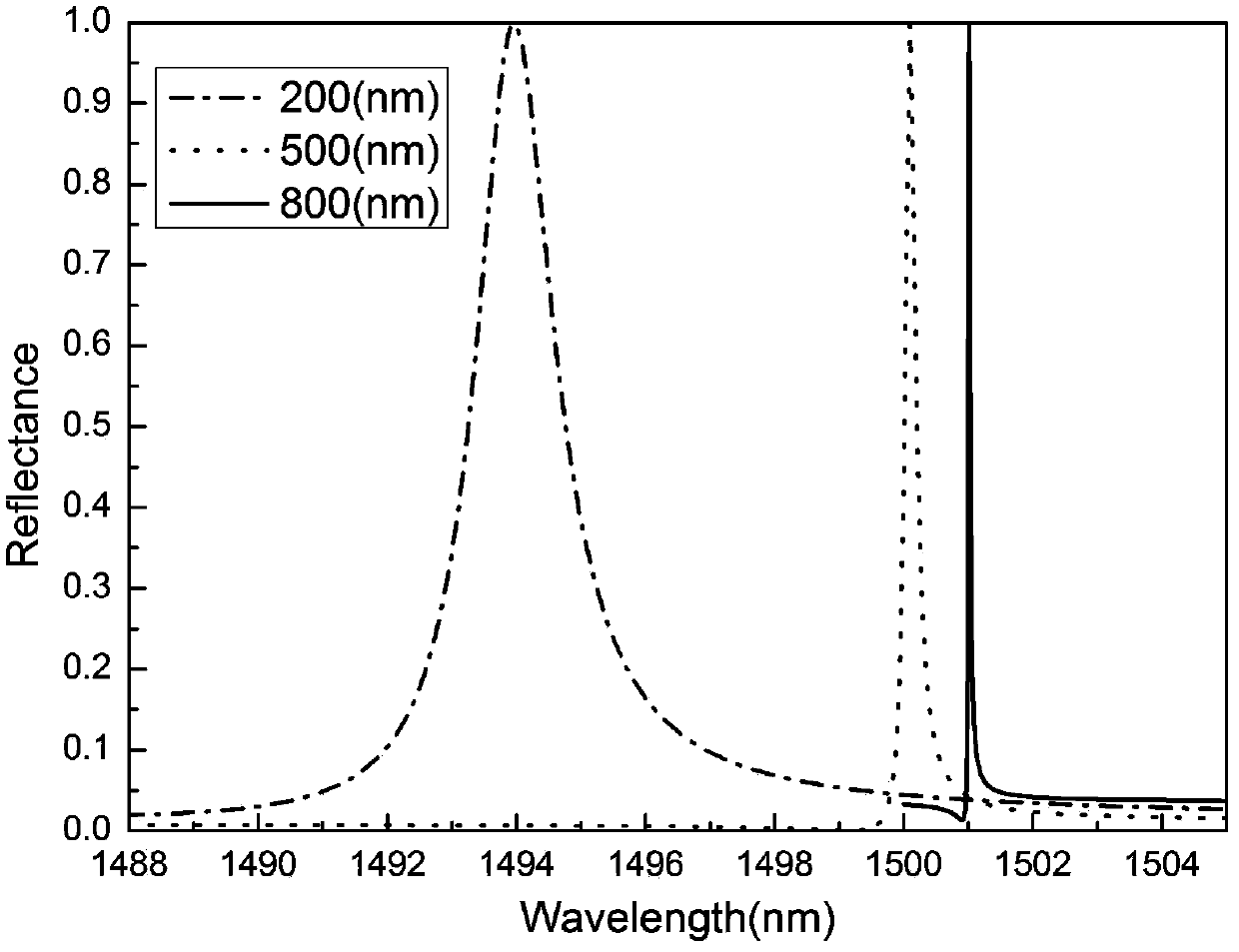

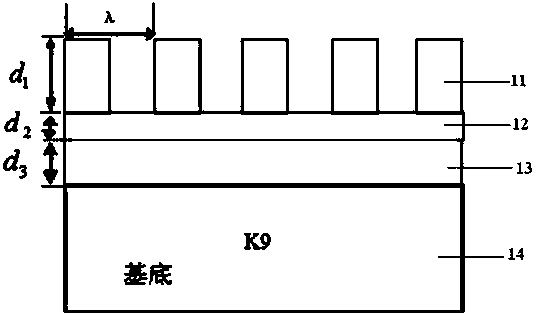

[0016] figure 1 It is a structural diagram of a guided mode resonant filter in an embodiment of the present invention; figure 2 It is the reflection spectrum diagram of the guided mode resonant filter in the embodiment of the present invention.

[0017] Such as figure 1 , 2 As shown, the structure of the filter used in the present invention includes: a substrate 14 , a grating layer 11 , an unsensitized photoresist layer 12 and a waveguide layer 13 . Thickness d of grating layer 11 1 , the thickness d of the unsensitized photoresist layer 12 2 and the thickness d of the waveguide layer 13 3 .

[0018] Steps for making a guided mode resonant filter.

[0019] Step 1: First, deposit a layer of titanium oxide film with high refractive index on the cleaned K9 glass substrate 11 by thermal evaporation.

[0020] Step 2: The transmission spectrum of the titanium oxide layer is calculated by Macleod software to obtain the thickness and refractive index of the actual film. Acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com