Solar cell and manufacturing method thereof

A technology of solar cells and manufacturing methods, applied in the field of solar cells, can solve problems such as lattice mismatch, achieve the effects of increasing yield, avoiding cracks and falling off, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

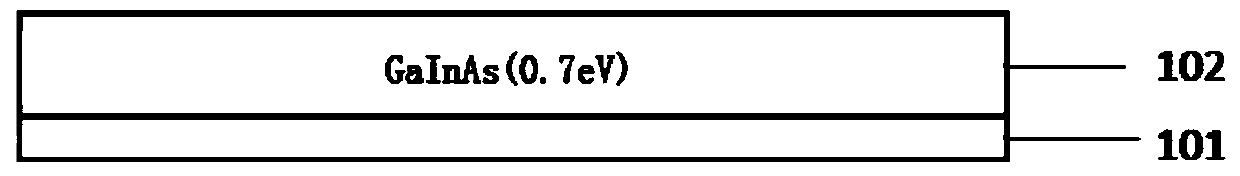

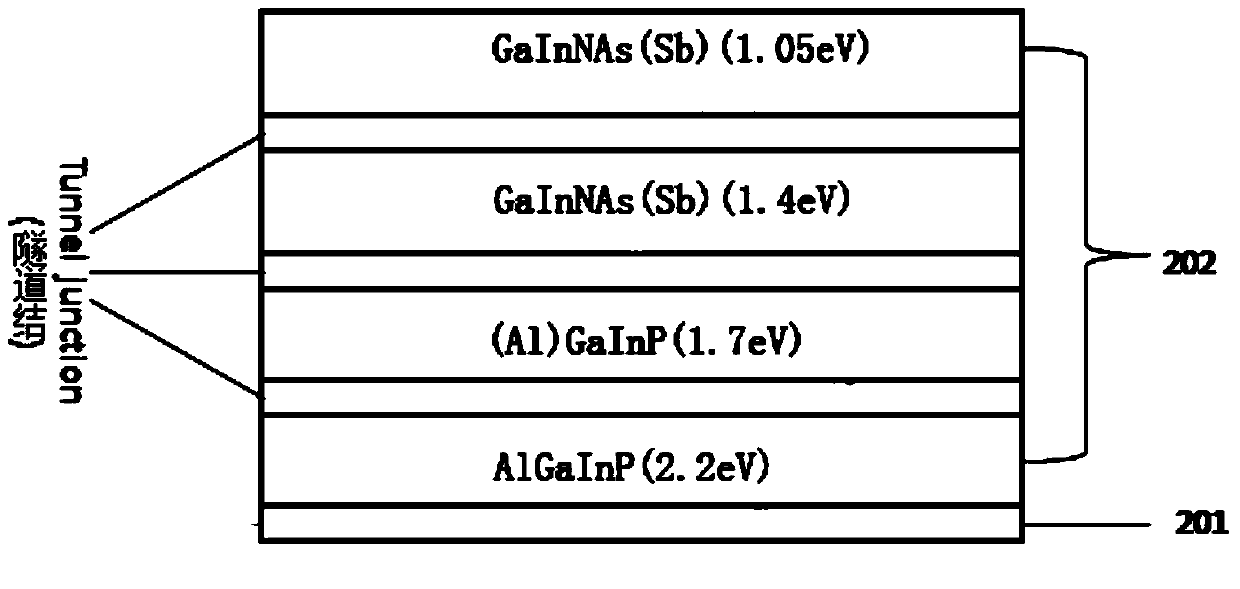

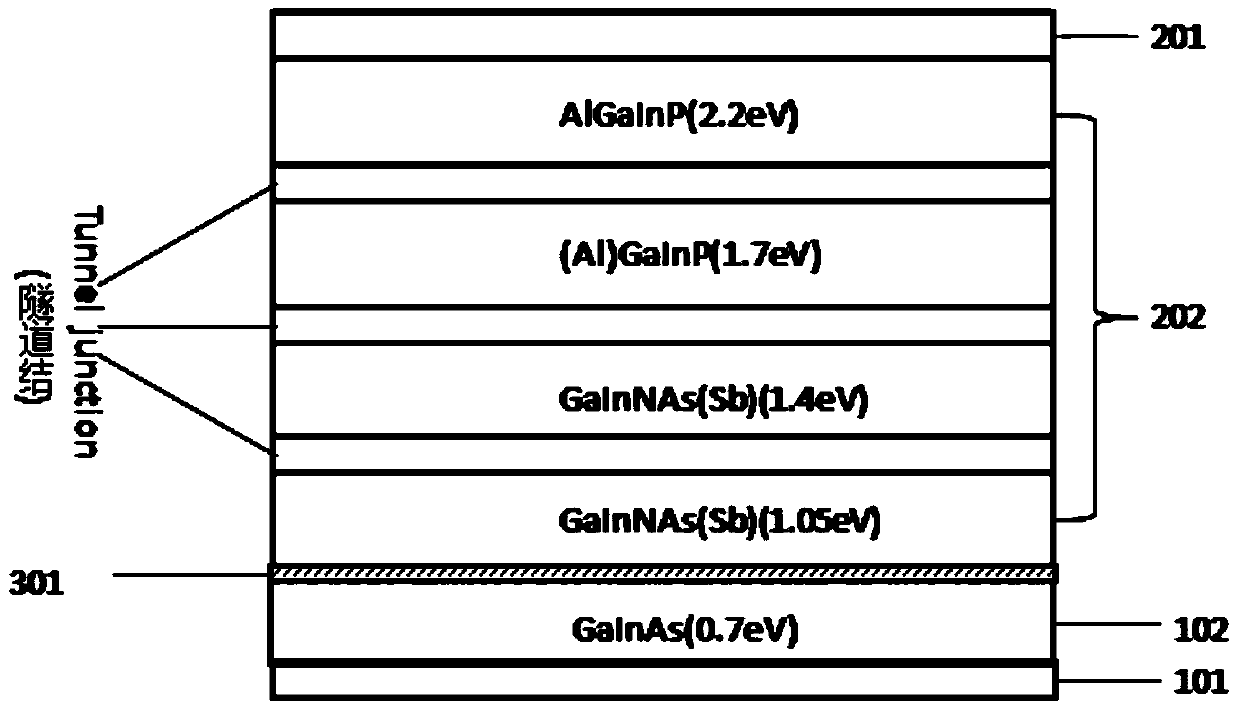

[0036] ginseng Figure 5 As shown, the solar cell includes a substrate 101, a GaInAs-based cell film layer 102 formed above the substrate 101, and a GaInAs-based cell film layer bonded AlGaInP / (Al)GaInP / GaInNAs(Sb) / GaInNAs(Sb) four-junction The battery film layer 202 further includes two electrodes electrically connected to the AlGaInP layer and the GaInAs-based battery film layer respectively.

[0037] The substrate 101 is an InP substrate, and may also be other substrates such as silicon, metal, or plastic.

[0038] The GaInAs-based battery film layer 102 and the AlGaInP / (Al)GaInP / GaInNAs(Sb) / GaInNAs(Sb) four-junction battery film layer 202 are bonded through the metal thin film layer 301 . In other embodiments, direct bonding methods such as eutectic, high temperature treatment, or electrostatic bonding may also be used between the two, and an inverted soldering process may also be used.

[0039] AlGaInP / (Al)GaInP / GaInNAs(Sb) / GaInNAs(Sb) four-junction cell film layer 202 ...

Embodiment 2

[0057] ginseng Figure 6 As shown, the solar cell includes a substrate 101, a GaInAs-based cell film layer 102 formed above the substrate 101, and a GaInAs-based cell film layer bonded AlGaInP / (Al)GaInP / GaInNAs(Sb) / GaInNAs(Sb) four-junction The battery film layer 202, the GaInAs-based battery film layer and the AlGaInP / (Al)GaInP / GaInNAs(Sb) / GaInNAs(Sb) four-junction battery film layer all adopt a double-layer mesa structure, and the GaInAs-based battery film layer and the AlGaInP / An electrode 401 , 402 , 403 and 403 is provided on the exposed surface of each mesa structure in the (Al)GaInP / GaInNAs(Sb) / GaInNAs(Sb) four-junction battery film layer. .

[0058] The substrate 101 is an InP substrate, and may also be other substrates such as silicon, metal, or plastic.

[0059] The GaInAs-based battery film layer 102 and the AlGaInP / (Al)GaInP / GaInNAs(Sb) / GaInNAs(Sb) four-junction battery film layer 202 are bonded through the metal thin film layer 301 . In other embodiments, dire...

no. 2 Embodiment

[0068] This embodiment provides a method for bonding an integrated GaInAs-based battery film layer 102 with an AlGaInP / (Al)GaInP / GaInNAs(Sb) / GaInNAs(Sb) four-junction battery film layer 202 and preparing a four-electrode terminal. The preparation process includes:

[0069] Step 1: Grow a GaInAs-based battery film layer 102 on an InP substrate 101 by MBE or MOCVD, and grow an AlGaInP / (Al)GaInP / GaInNAs(Sb) / GaInNAs(Sb) four-junction inverted on the GaAs substrate 201 Battery film layer 202 .

[0070] Step 2: Bond the GaInNAs(Sb) surface of the AlGaInP / (Al)GaInP / GaInNAs(Sb) / GaInNAs(Sb) four-junction battery film layer 202 to the exposed surface of the GaInAs-based battery film layer 102 by wafer bonding technology.

[0071] After the AlGaInP / (Al)GaInP / GaInNAs(Sb) / GaInNAs(Sb) four-junction battery film layer 202 and the GaInAs-based battery film layer 102 were respectively organically cleaned, they were soaked in a hydrogen fluoride solution with a volume ratio of 7:100 for 30 se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com