Composite of metal and thermoplastic resin

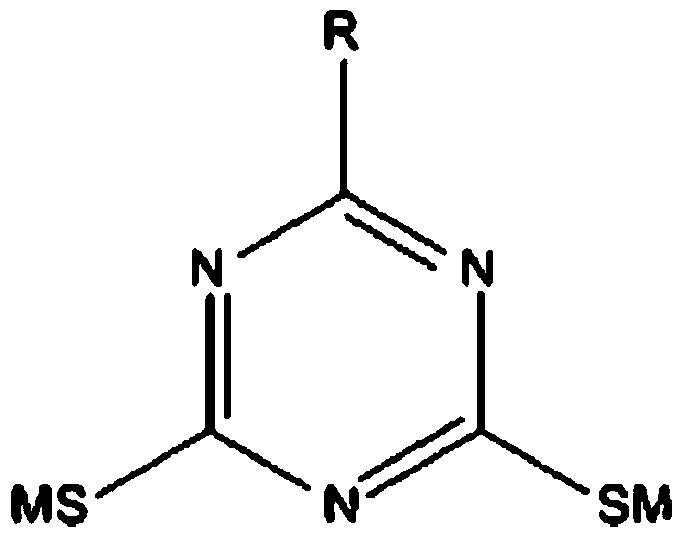

A thermoplastic resin, composite technology, used in metal layered products, electronic equipment, household components, etc., can solve the problems of insufficient chemical resistance, reduced component function, insufficient rigidity, etc., to improve the fixed state and improve the electrical conductivity. The effect of high sexual and reinforcing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

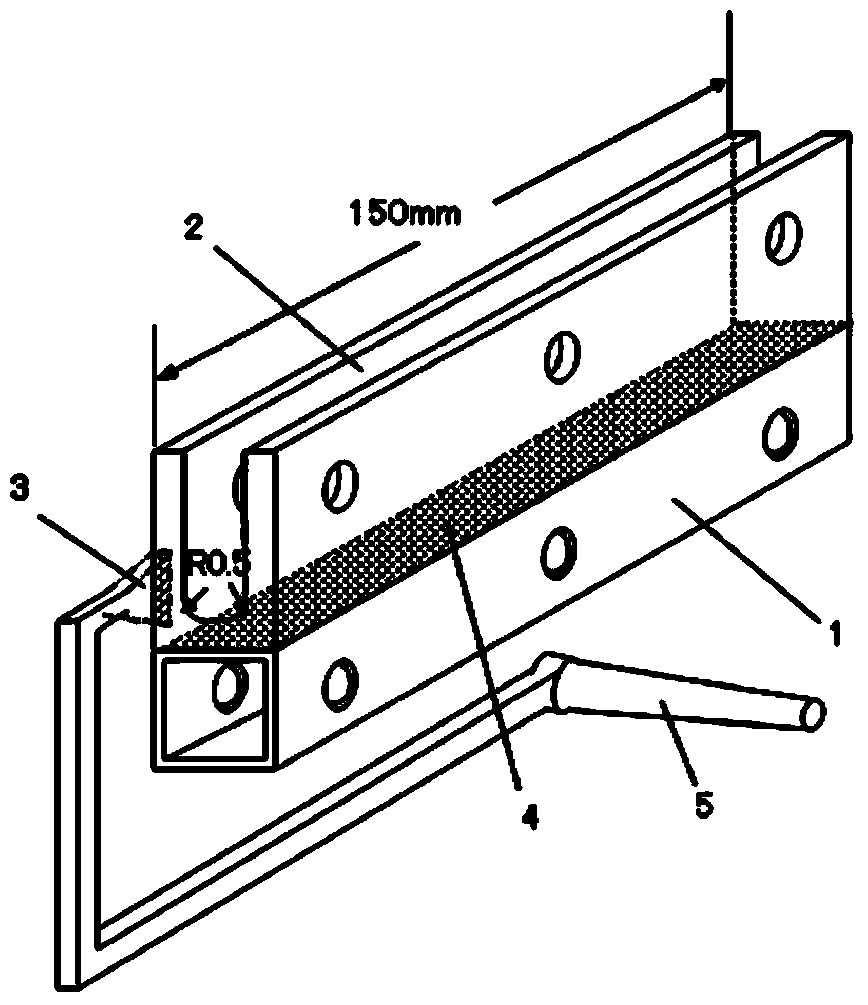

[0114] Use the natural convection dryer SONW-450 of Azowan Co., Ltd. set at 200°C to preheat the aluminum test piece surface-treated through treatment 1, and set the test piece at a place where it can be molded. figure 1 In the mold of the composite body, the mold is installed on the injection molding machine SE-100D of Sumitomo Heavy Industries Co., Ltd., and the poly The amide resin composition is introduced into the injection molding machine, and injected into a mold with a mold temperature of 150°C at a resin temperature of 260°C, and after applying a holding pressure of 40MPa for 40 seconds, it is cooled in the mold for 45 seconds to obtain figure 1 complex of shapes. The strength measurement and bondability evaluation of the obtained composite were performed. Moreover, the measurement of the linear expansion coefficient was performed based on the cut-out test piece. The results are shown in Table 1.

Embodiment 2

[0116] A composite was obtained in the same manner as in Example 1 except that (a-1) was 25% by mass and (a-6) was 75% by mass in Example 1. The strength measurement and bondability evaluation of the obtained composite were performed. Moreover, the measurement of the linear expansion coefficient was performed based on the cut-out test piece. The results are shown in Table 1.

Embodiment 3

[0118] A composite was obtained in the same manner as in Example 1 except that (a-1) was 50% by mass and (a-6) was 50% by mass in Example 1. The strength measurement and bondability evaluation of the obtained composite were performed. In addition, the linear expansion coefficient and the crystallization temperature were measured based on the cut-out test pieces. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com