Electrochromic devices with anti-iridescence coatings

An electrochromic and coating technology, applied in the direction of coating, layered products, glass/slag layered products, etc., can solve the problem of color generation and achieve the effect of high incident angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

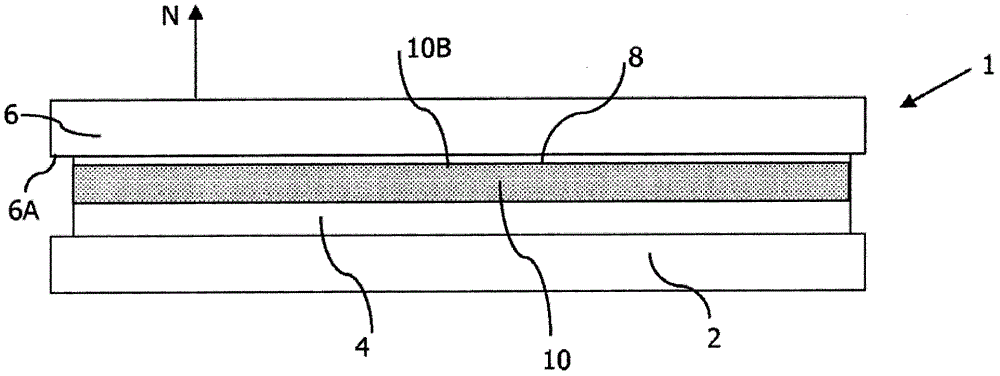

[0114] Substrate 2 is a 6 mm thick sheet of soda-lime-silicate glass.

[0115] Functional system 4 is a solid-state electrochromic system that is deposited directly on substrate 2 and consists of the following stack, starting from substrate 2:

[0116] 500nm thick ITO layer, which forms the first electrode coating / 55nm thick iridium oxide layer, which forms the first electrochromic layer / 150nm thick tungsten oxide and 300nm thick tantalum oxide layer, which forms the electrolyte / 400nm thick doped h + Tungsten oxide, which forms the second electrochromic layer / 100nm thick ITO layer, which forms the second electrode coating.

[0117] The laminate interlayer is in contact with the functional system 4 . The laminated interlayer consisted of 0.76 thick polyurethane boards.

[0118] Reflection control coating 8 is 70nm thick Si 3 N 4 layer.

[0119] The reflection control paint 8 is deposited directly on the counter substrate 6 .

[0120] The laminated interlayer 10 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com