Livestock feed and preparation method thereof

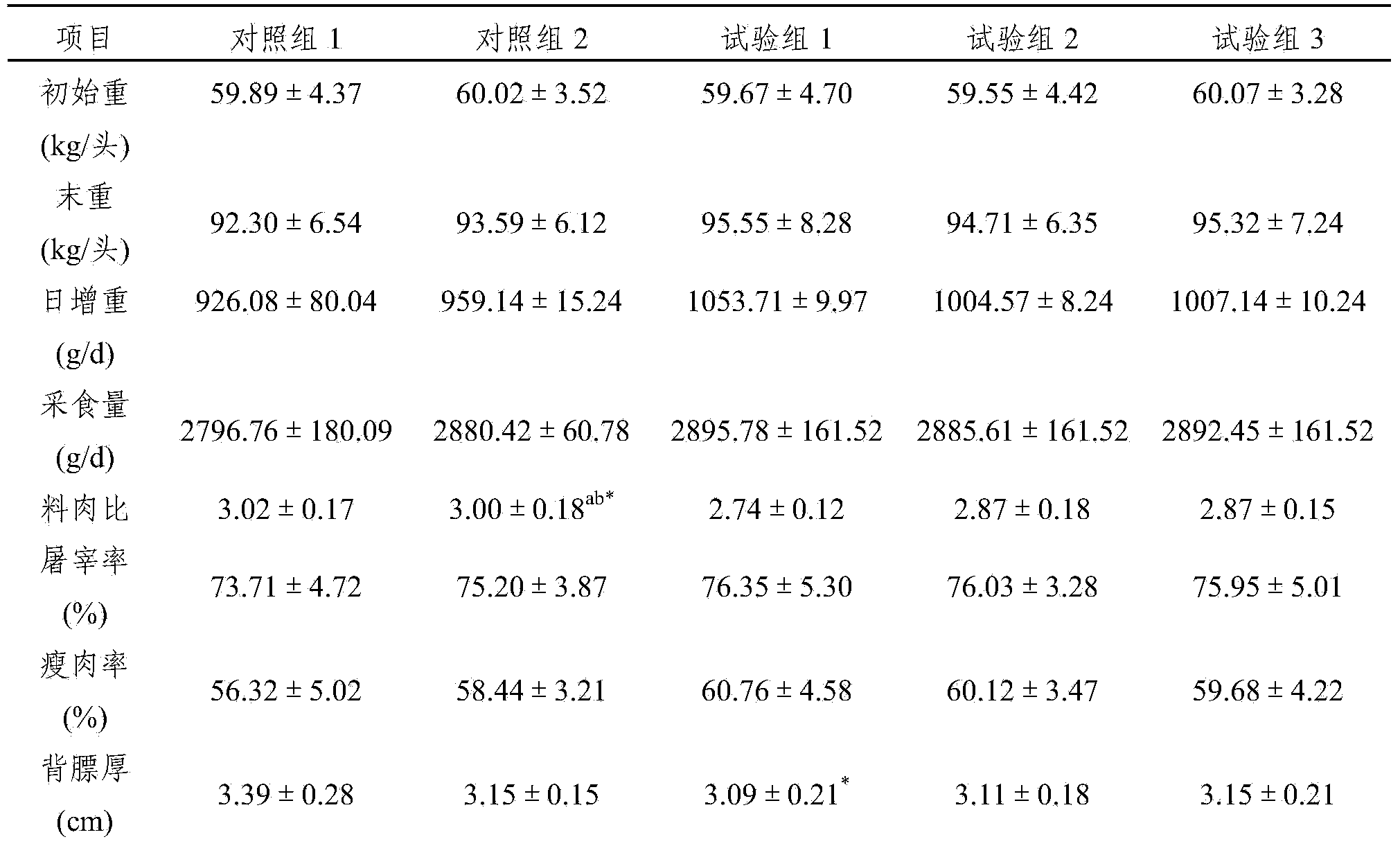

A technology of feed and fermented feed, which is applied in the field of feed and microbial fermentation, can solve the problems of unsafe, high cost, low extraction rate, etc., and achieve the effects of easy digestion, reduction of feed-to-meat ratio of livestock and poultry, and low content of anti-nutritional factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Mix 20kg of perilla powder, 16kg of rattan tea powder, and 10kg of corn flour evenly, then add 20kg of molasses (fresh wet basis) and 200kg of clean water to make a thick slurry, heat up to 95°C, soak and sterilize for 4 hours, then cool down, wait for When the temperature drops to 36-37°C, add 12kg of compound seed liquid (including 8kg of Bacillus licheniformis seed liquid and 4.0kg of Lactobacillus plantarum seed liquid). Soybean meal powder, 150kg puffed soybean powder, 150kg bran and 60kg4% premix, after second solid-state fermentation for 72 hours, dried to make perilla and rattan tea growth-promoting fermented feed.

Embodiment 2

[0028] Mix 2kg of perilla powder, 20kg of rattan tea powder, and 1kg of corn flour evenly, then add 20kg of molasses (fresh wet basis) and 100kg of clean water to make a thick slurry, heat up to 100°C, soak and sterilize for 4 hours, then cool down. When the temperature drops to 36-37°C, add 5kg of compound seed liquid (including 3kg of Bacillus licheniformis seed liquid and 2kg of plant Lactobacillus seed liquid), and after a thick slurry fermentation for 96 hours, mix in 800kg of corn flour and 100kg of puffed soybean meal Flour, 50kg puffed soybean powder, 150kg bran, after second solid state fermentation for 72h, dry to make perilla and rattan tea growth-promoting fermented feed.

Embodiment 3

[0030] Mix 200kg of perilla powder, 200kg of rattan tea powder, and 120kg of corn flour evenly, then add 180kg of molasses (fresh wet basis) and 2500kg of clean water to make a thick slurry, heat up to 95°C, soak and sterilize for 4 hours, then cool down. When the temperature drops to 35-36°C, add 160kg of compound seed liquid (including 100kg of Bacillus licheniformis seed liquid and 60.0kg of plant Lactobacillus seed liquid). Soybean meal powder, 1200kg of expanded soybean meal, 1000kg of bran and 600kg of 4% premix, and after a second solid-state fermentation for 72 hours, were dried to make perilla and rattan tea growth-promoting fermented feed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com