Biodiesel reaction still

A biodiesel and reaction kettle technology, applied in the field of chemical equipment, can solve the problems of inability to meet high-efficiency production, poor heating effect, and high production cost, and achieve the effects of improving heat exchange efficiency, low equipment cost, and improving thermal insulation capability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

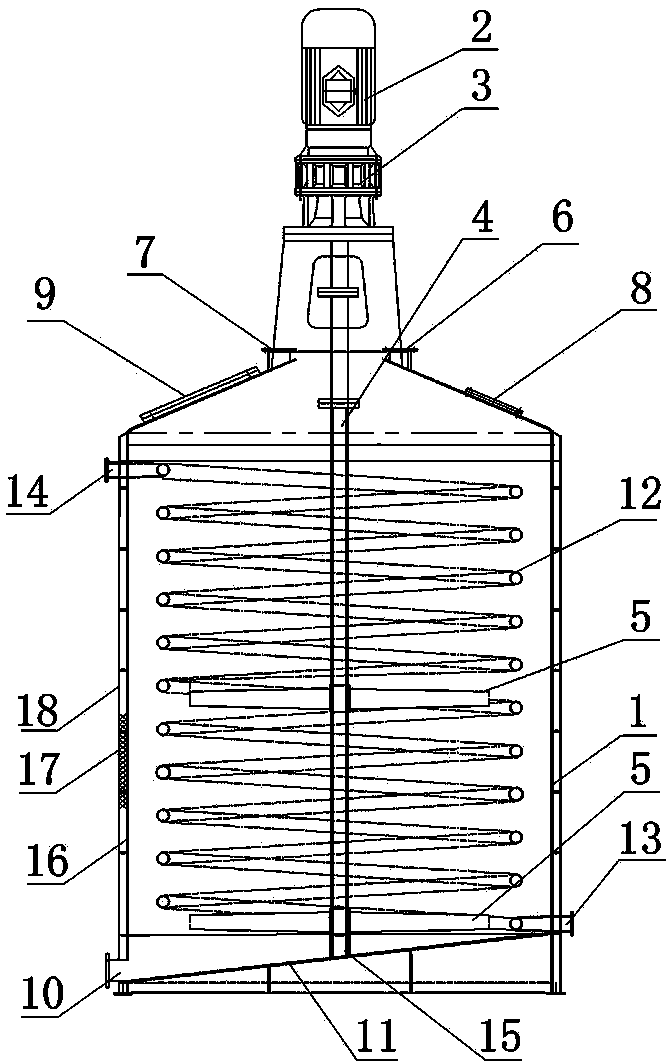

[0012] Such as figure 1 As shown, the biodiesel reactor includes a container 1, the top of the container 1 is equipped with a transmission device through the machine base, and the transmission device includes a motor 2 and a reducer 3, and the output end of the reducer 3 is equipped with a stirring shaft 4. The stirring shaft 4 extends into the container 1, and blades 5 are installed on the stirring shaft 4 in the container 1. The top of the container 1 is provided with a feed port A6, a feed port B7, an observation hole 8 and an inspection hole 9. The container 1 The bottom of the side wall is provided with a discharge port 10, the bottom surface of the container 1 is an inclined plane 11 inclined to the discharge port 10, a spiral heating tube 12 is also provided in the container 1, and the corresp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com