Catalyst for methyl tert-butyl ether cracking reaction to prepare isobutene and preparation method thereof

A technology of methyl tert-butyl ether and isobutylene, which is applied in the field of cracking catalysts and its preparation, can solve the problems of easy drop-off of sulfonic acid groups, short service life of catalysts, and deactivation of catalysts, and achieve high temperature resistance, high activity, highly selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

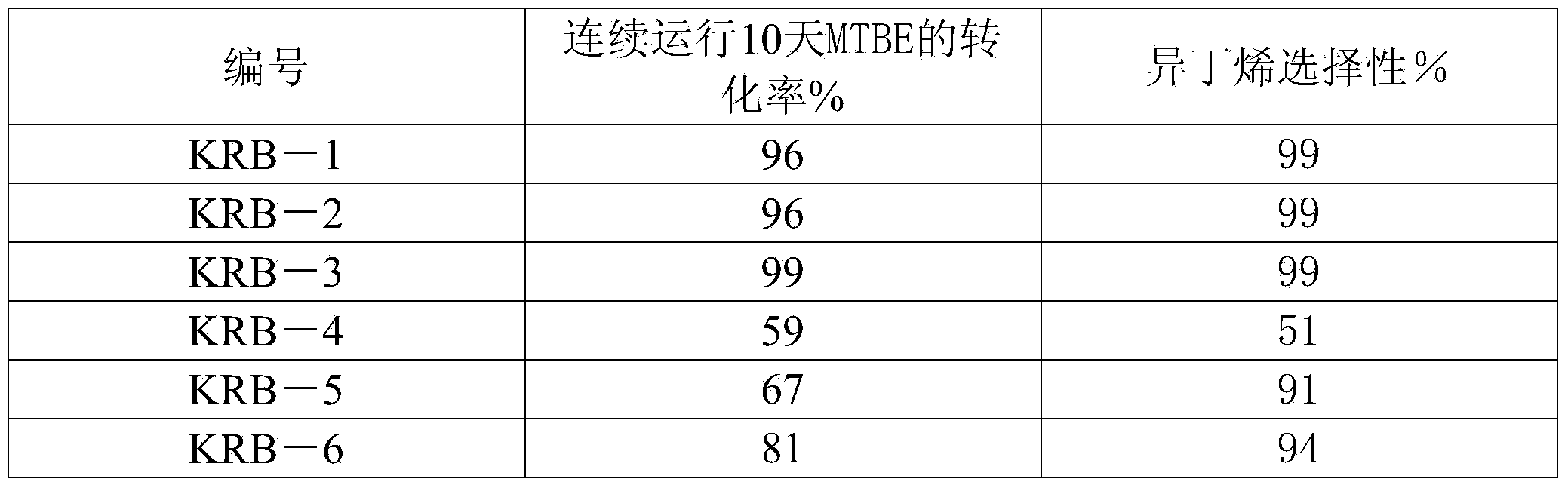

Embodiment 1

[0019] Put the perfluorosulfonic acid resin into the reaction kettle, add methanol as a dispersant, in terms of mass, methanol / perfluorosulfonic acid resin = 400%; then add boron trifluoride ether solution, the solution mass concentration is 30% , by mass, boron trifluoride / perfluorosulfonic acid resin = 5%, the temperature is 50°C, stirred for 48 hours, and washed repeatedly with methanol to obtain the reaction catalyst product of methyl tert-butyl ether cracking to isobutylene, the code is KRB- 1.

Embodiment 2

[0021] On a mass basis, boron trifluoride / perfluorosulfonic acid resin=10%, and the others are the same as in Example 1, and the obtained product number is KRB-2.

Embodiment 3

[0023] In terms of mass, boron trifluoride / perfluorosulfonic acid resin=20%, the others are the same as in Example 1, and the obtained product number is KRB-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com