Screening equipment for promoting output of color zone of white-light LED lamp bead and screening method thereof

A technology of LED lamp beads and screening equipment, which is applied in chemical instruments and methods, separating solids from solids with airflow, filtering and sieving, etc., can solve the problem of low output rate of LED lamp bead color area and affect product reliability and other issues to achieve stable efficiency, stable internal conditions, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

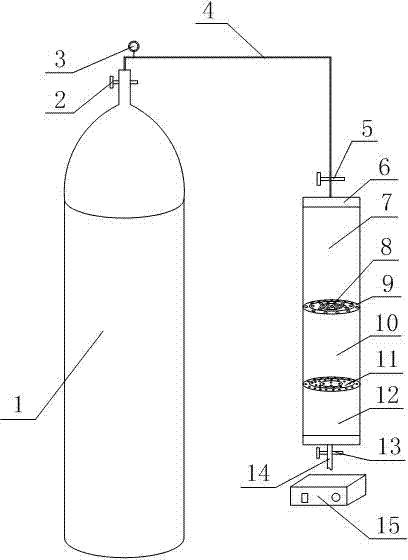

[0022] Such as figure 1 As shown, the screening equipment used to improve the output of the white LED lamp bead color area includes an internal hollow screening equipment 6, and the inside of the screening equipment 6 is provided with several layers of filter membranes, and there are gaps between each layer of filter membranes , the outer wall of the filter membrane is in contact with the inner wall of the screening device 6 to form a sealed structure, and the center of each layer of filter membrane is arranged on the same lead vertical line, each layer of filter membrane is provided with a filter through hole, and the filter set above The aperture of the filter through-hole in the membrane is greater than the aperture of the filter through-hole in the adjacent filter membrane below it; one end of the screening device 6 is connected with a steel cylinder 1 filled with nitrogen, and the other end is provided with a magnetic stirrer 15, a magnetic stirrer 15 It is arranged direc...

Embodiment 2

[0025] Such as figure 1 As shown, on the basis of Example 1, the gas outlet of the steel cylinder 1 is connected with a pipeline 4, the pipeline 4 communicates with the inside of the screening device 6, the pipeline 4 is provided with a barometer 3, and the barometer 3 is arranged on the steel cylinder 1 and Between the screening equipment 6; the pipeline 4 is provided with a valve one 2, the valve one 2 is arranged at the gas outlet position of the steel cylinder 1, and the valve one 2 is arranged between the steel cylinder 1 and the barometer 3; the pipeline 4 is provided with Valve two 5, valve two 5 are arranged between the barometer 3 and the screening equipment 6; An outlet pipe 14 is arranged between the screening equipment 6 and the magnetic stirrer 15, and one end of the outlet pipe 14 communicates with the inside of the screening equipment 6. The centerline of the trachea 14 coincides with the centerline of the screening device 6 , the outlet pipe 14 is provided with...

Embodiment 3

[0027] The screening method used to improve the output of the white LED lamp bead color area, open the screening equipment, install two filter membranes with pore diameters of 13 μm and 15 μm in the screening equipment to form three filter chambers, and filter membranes with a pore size of 15 μm Set it directly above the filter membrane 2 with a pore size of 13 μm, keep the same distance between the filter membranes, and close the valve 3 at the same time; prepare fluorescent glue by purchasing phosphor powder with a marked particle size of 15 μm, the particle size error of the phosphor powder It is ±1μm. Stir the fluorescent glue, a total of 100g, and put it into the first-stage filter chamber. After the magnets are installed in the first-stage filter chamber and the second-stage filter chamber, seal the screening equipment and fix it on the iron stand , so that the screening equipment is directly above the magnetic stirrer, and the screening equipment is connected to the ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com