Technology for utilizing abandoned agaric bags to make plates through hot pressing

A technology for pressing boards and fungus, which is applied in the direction of flat products, wood processing appliances, household components, etc., can solve the problem of affecting the scope of application of waste fungus bag boards, not suitable for processing boards from the contents of waste fungus bags, and difficulty in achieving board density and static To solve problems such as bending strength, achieve the best economic and social benefits, high production efficiency, and no environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

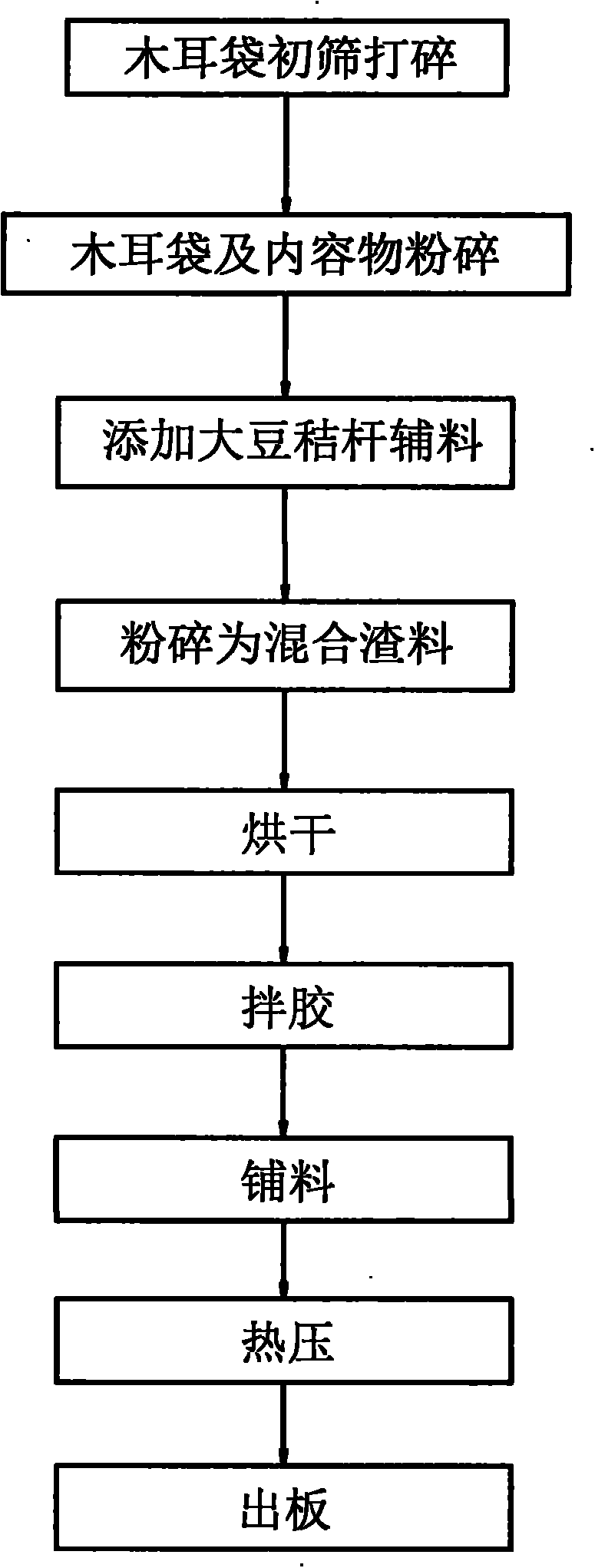

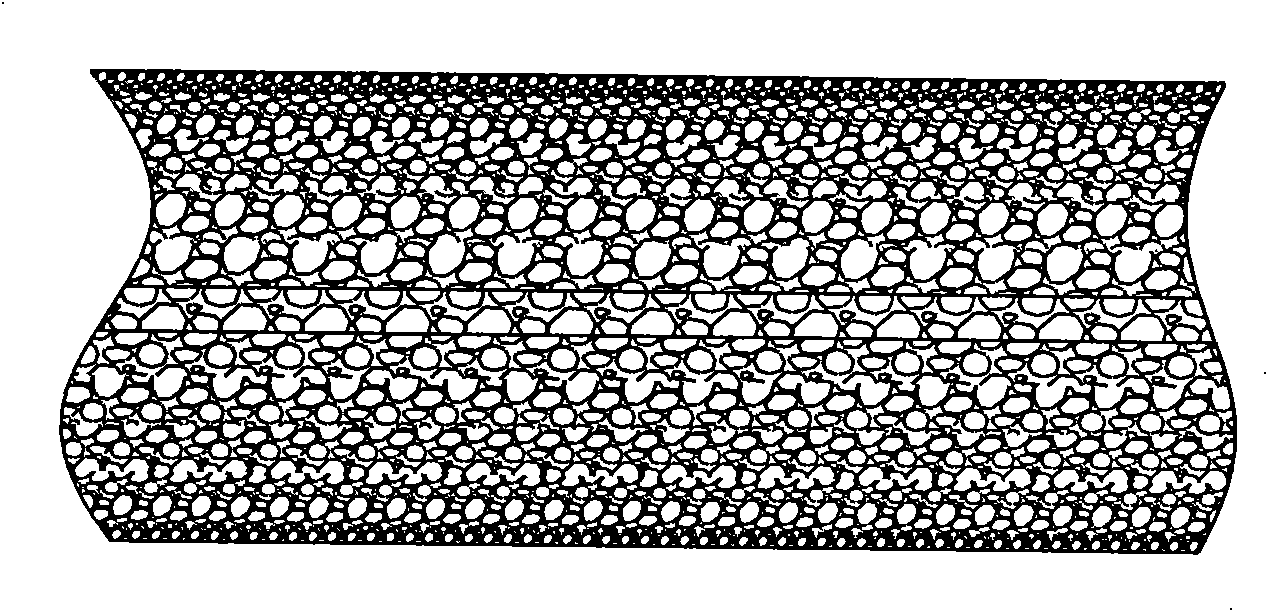

[0036] Attached below figure 1 , attached figure 2 The present invention is described in detail below.

[0037] Such as figure 1 , figure 2 As shown, the present invention mixes the contents of discarded fungus bags with 30% soybean stalks evenly, after crushing and drying, adds a certain amount of urea-formaldehyde resin and additives, stirs, paves, and hot-presses to make qualified artificial boards ; The thickness of the artificial sheet is 8-12mm and the density of the artificial sheet is 0.7-0.8g / cm 3 ; The static bending strength of the artificial board is 10-13MPA.

[0038] The steps are:

[0039] 1) At the site where the discarded fungus bags are purchased, the discarded fungus bags are initially screened and crushed;

[0040] The waste fungus bag is a cylindrical plastic bag with both ends sealed, and the inside is filled with a nutrient matrix. In order to ensure the subsequent crushing operation, the waste fungus bag needs to be peeled first. After removing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Static bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com